Toyota Yaris: Air Fuel Ratio Sensor (for Sensor 2) / Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed, installed, or replaced during the No. 2 air fuel ratio sensor removal/installation are shown below.

Necessary Procedure After Parts Removed/Installed/Replaced| Replacement Part or Procedure | Necessary Procedure | Effect/Inoperative when not Performed | Link |

|---|---|---|---|

| Inspection after repair |

|

|

CAUTION:

-

When the engine is hot, do not touch high-temperature areas such as the engine or exhaust pipe.

- Touching high-temperature areas such as the engine and exhaust pipe could result in burns.

PROCEDURE

1. REMOVE CENTER NO. 4 ENGINE UNDER COVER

Click here

2. REMOVE CENTER FRONT FLOOR BRACE

Click here

3. REMOVE CENTER NO. 1 FLOOR BRACE

Click here

4. REMOVE NO. 2 AIR FUEL RATIO SENSOR

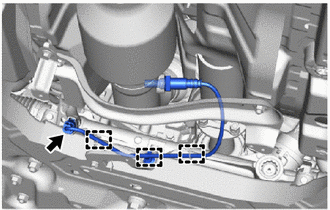

| (a) Disconnect the No. 2 air fuel ratio sensor connector. |

|

(b) Disengage the 3 wire harness clamps.

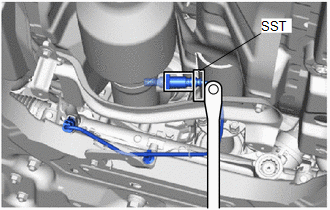

| (c) Using SST, remove the No. 2 air fuel ratio sensor from the front exhaust pipe assembly. SST: 09224-00012 NOTICE: If the No. 2 air fuel ratio sensor has been struck or dropped, replace it. |

|

Components

Components

COMPONENTS ILLUSTRATION

*1 NO. 2 AIR FUEL RATIO SENSOR *2 CENTER NO. 1 FLOOR BRACE *3 CENTER FRONT FLOOR BRACE *4 CENTER NO. 4 ENGINE UNDER COVER

N*m (kgf*cm, ft...

Inspection

Inspection

INSPECTION PROCEDURE 1. INSPECT NO. 2 AIR FUEL RATIO SENSOR (a) Measure the resistance according to the value(s) in the table below. Standard Resistance: Tester Connection Condition Specified Condition D109-1(HA1B) - D109-2(+B) 20°C (68°F) 1...

Other information:

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Turbocharger Noise

DESCRIPTION HINT: Turbocharger noise is classified into two types. These are whistling sound and chattering sound. During troubleshooting, first determine the type of noise. Type of Abnormal Noise Outline of Abnormal Noise Major Trouble Area Whistling sound (airflow sound) The whistling sound volume and pitch are proportional to the turbocharger or engine speed...

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Backup Boost Converter "A" Control CPU Signal Invalid (P060629)

DESCRIPTION The engine stop and start ECU can detect open circuits when signals such as the boost, standby request or overheating signal cannot be sent to the backup boost converter control IC from the stop and start control IC in the engine stop and start ECU...

Categories

- Manuals Home

- Toyota Yaris Owners Manual

- Toyota Yaris Service Manual

- Fuel Gauge

- G16e-gts (engine Mechanical)

- How to connect USB port/Auxiliary jack

- New on site

- Most important about car

Fuel Gauge

The fuel gauge shows approximately how much fuel is remaining in the tank when the ignition is switched ON. We recommend keeping the tank over 1/4 full.