Toyota Yaris: Air Fuel Ratio Sensor (for Sensor 2) / Inspection

INSPECTION

PROCEDURE

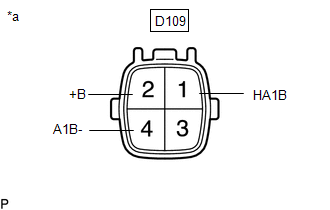

1. INSPECT NO. 2 AIR FUEL RATIO SENSOR

| (a) Measure the resistance according to the value(s) in the table below. Standard Resistance:

If the result is not as specified, replace the No. 2 air fuel ratio sensor. |

|

Removal

Removal

REMOVAL CAUTION / NOTICE / HINT The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed, installed, or replaced during the No...

Installation

Installation

INSTALLATION PROCEDURE 1. INSTALL NO. 2 AIR FUEL RATIO SENSOR (a) Using SST, install the No. 2 air fuel ratio sensor to the front exhaust pipe assembly...

Other information:

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Components

C..

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Brake Actuator Operation Sound is Loud during Initial Check

CAUTION / NOTICE / HINT NOTICE: After replacing the skid control ECU (brake actuator assembly), perform "Calibration". Click here PROCEDURE 1. PERFORM ROAD TEST (a) After turning the ignition switch to ON, compare the operating sound of the brake actuator the first time the vehicle speed reaches approximately 25 km/h (16 mph) with a known good vehicle of the same model...

Categories

- Manuals Home

- Toyota Yaris Owners Manual

- Toyota Yaris Service Manual

- How to use USB mode

- Engine Start Function When Key Battery is Dead

- Removal

- New on site

- Most important about car

Break-In Period

No special break-in is necessary, but a few precautions in the first 600 miles (1,000 km) may add to the performance, economy, and life of the vehicle.

Do not race the engine. Do not maintain one constant speed, either slow or fast, for a long period of time. Do not drive constantly at full-throttle or high engine rpm for extended periods of time. Avoid unnecessary hard stops. Avoid full-throttle starts.

Copyright © 2026 www.toyaris4.com