Toyota Yaris: Engine Assembly / Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed, installed, or replaced during the engine assembly removal/installation are shown below.

Necessary Procedure After Parts Removed/Installed/Replaced| Replaced Part or Performed Procedure | Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed | Link |

|---|---|---|---|

| Inspection After Repair |

|

|

| Front wheel alignment adjustment | ECU Data Initialization | Active torque split AWD system |

|

| Calibration |

|

|

CAUTION:

-

Because the weight of the engine with transaxle assembly is extremely heavy, make sure to follow the work procedures described in the repair manual.

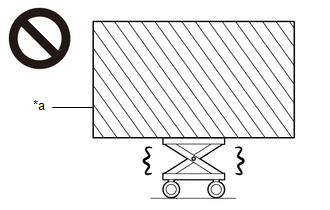

*a

Heavy object exceeding the capacity of the engine lifter

- If work is not performed according to the procedures described in the repair manual, there is a danger that the engine lifter could drop and components could fall down.

-

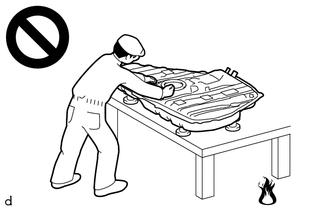

Do not touch the engine or exhaust manifold converter sub-assembly when they are hot.

*a

High temperature areas

- Touching the engine or exhaust manifold converter sub-assembly when they are hot could result in burns.

-

Never perform work on fuel system components near any possible ignition sources.

- Vaporized fuel could ignite, resulting in a serious accident.

-

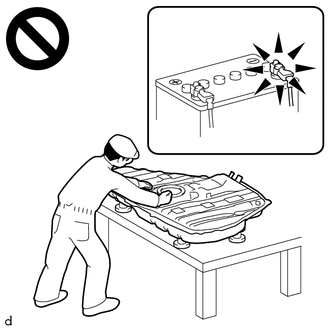

Do not perform work on fuel system components without first disconnecting the cable from the negative (-) auxiliary battery terminal.

- Sparks could cause vaporized fuel to ignite, resulting in a serious accident.

NOTICE:

This procedure includes the removal of small-head bolts. Refer to Small-Head Bolts of Basic Repair Hint to identify the small-head bolts.

Click here

HINT:

When the cable is disconnected / reconnected to the auxiliary battery terminal, systems temporarily stop operating. However, each system has a function that completes learning the first time the system is used.

-

Learning completes when vehicle is driven

Effect/Inoperative Function When Necessary Procedures are not Performed

Necessary Procedures

Link

Lane tracing assist system

Drive the vehicle straight ahead at 35 km/h (22 mph) or more for 5 second or more.

Pre-collision system

Stop and start system

Drive the vehicle until stop and start control is permitted (approximately 5 to 60 minutes)

-

Learning completes when vehicle is operated normally

Effect/Inoperative Function When Necessary Procedures are not Performed

Necessary Procedures

Link

Power door lock control system

- Back door opener

Perform door unlock operation with door control switch or electrical key transmitter sub-assembly switch.

Air conditioning system

After the ignition switch is turned to ON, the servo motor standard position is recognized.

-

PROCEDURE

1. PRECAUTION

NOTICE:

After turning the engine switch off, waiting time may be required before disconnecting the cable from the negative (-) auxiliary battery terminal. Therefore, make sure to read the disconnecting the cable from the negative (-) auxiliary battery terminal notices before proceeding with work.

Click here

2. RECOVER REFRIGERANT FROM REFRIGERATION SYSTEM

Click here

3. DISCHARGE FUEL SYSTEM PRESSURE

Click here

4. DISCONNECT CABLE FROM NEGATIVE AUXILIARY BATTERY TERMINAL

Click here

5. ALIGN FRONT WHEELS FACING STRAIGHT AHEAD

6. REMOVE FRONT WHEELS

Click here

7. REMOVE NO. 1 ENGINE UNDER COVER ASSEMBLY

Click here

8. REMOVE ENGINE UNDER COVER RH

Click here

9. REMOVE ENGINE UNDER COVER LH

Click here

10. REMOVE CENTER NO. 4 ENGINE UNDER COVER

Click here

11. SEPARATE FRONT FENDER LINER LH

Click here

12. SEPARATE FRONT FENDER LINER RH

Click here

13. DRAIN ENGINE OIL

Click here

14. DRAIN ENGINE COOLANT

Click here

15. DRAIN MANUAL TRANSAXLE OIL

Click here

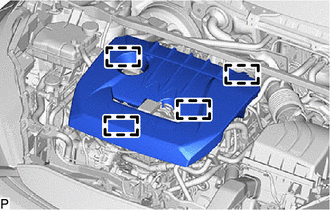

16. REMOVE NO. 1 ENGINE COVER SUB-ASSEMBLY

| (a) Disengage the 4 clamps and remove the No. 1 engine cover sub-assembly. NOTICE: Attempting to disengage both front and rear clips at the same time may cause the No. 1 engine cover sub-assembly to break. |

|

17. REMOVE WINDSHIELD WIPER MOTOR AND LINK

Click here

18. REMOVE NO. 1 FRONT VENTILATOR SEAL

Click here

19. REMOVE WATER GUARD PLATE RH

Click here

20. REMOVE OUTER COWL TOP PANEL SUB-ASSEMBLY

Click here

21. REMOVE AIR CLEANER ASSEMBLY

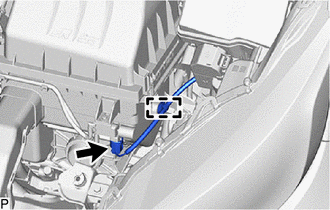

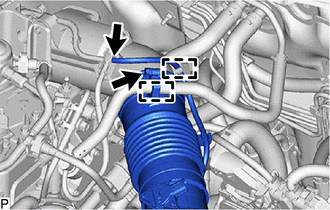

| (a) Disconnect the vacuum switching valve connector. |

|

(b) Disengage the clamp from the air cleaner cap sub-assembly.

| (c) Disconnect the mass air flow meter connector. |

|

(d) Disengage the clamp from the air cleaner cap sub-assembly.

| (e) Remove the 2 clips. |

|

| (f) Disconnect the vacuum transmitting hose. |

|

(g) Disengage the clamp from the intake air pipe.

(h) Disconnect the vacuum hose assy.

(i) Loosen the hose clamp.

(j) Remove the air cleaner assembly.

22. REMOVE AIR CLEANER BRACKET

| (a) Disengage the clamp from the air cleaner bracket. |

|

(b) Remove the 2 bolts and air cleaner bracket from the vehicle.

23. REMOVE NO. 1 RELAY BLOCK COVER

| (a) Remove the 3 claws and No. 1 relay block cover from the engine room relay block. |

|

24. REMOVE JUNKTION BLOCK COVER

| (a) Remove the junktion block cover. |

|

25. DISCONNECT WIRE HARNESS

| (a) Disengage the clamp to separate the engine wire from the vehicle. |

|

(b) Remove the 2 bolts to separate the engine wire from the vehicle.

| (c) Disengage the clamp to separate the engine wire from the vehicle. |

|

| (d) Remove the 2 nuts. |

|

(e) Disconnect the 3 connectors from the engine room relay block.

(f) Disengage the 2 claws to separate the engine wire from the engine room relay block.

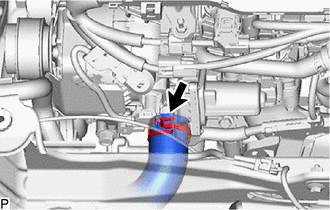

26. DISCONNECT NO. 1 RADIATOR HOSE

| (a) Slide the clip and disconnect the No. 1 radiator hose from the water outlet. |

|

27. DISCONNECT NO. 2 RADIATOR HOSE

| (a) Slide the clip and disconnect the No. 2 radiator hose from the water inlet with thermostat sub-assembly. |

|

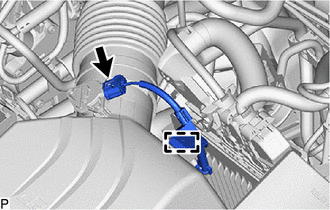

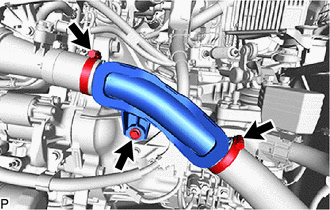

28. REMOVE NO. 2 AIR TUBE

| (a) Loosen the 2 hose clamps. |

|

(b) Remove the bolt and remove the No. 2 air tube.

29. REMOVE ECM

Click here

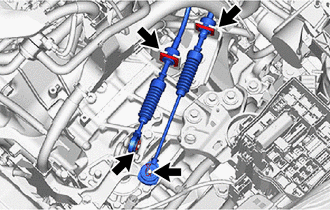

30. DISCONNECT TRANSMISSION CONTROL CABLE ASSEMBLY

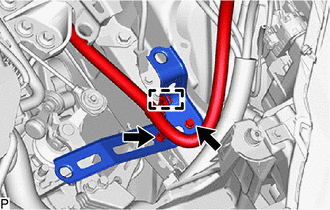

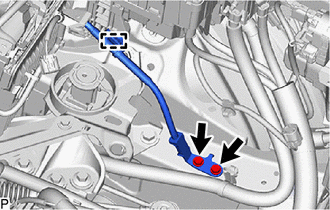

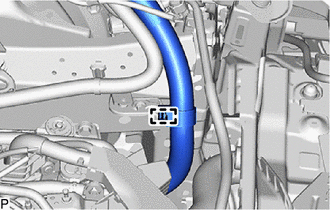

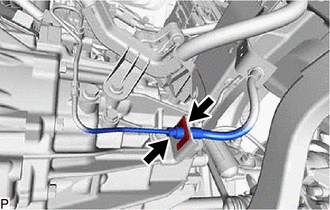

| (a) Remove the 2 clips A to disconnect the transmission control cable assembly from the manual transaxle assembly. |

|

(b) Remove the 2 clips B to disconnect the transmission control cable assembly from control cable bracket assembly.

31. DISCONNECT UNION TO CONNECTOR TUBE HOSE

Click here

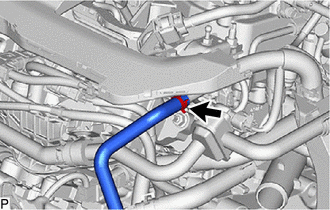

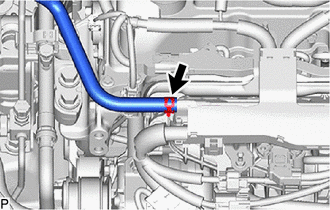

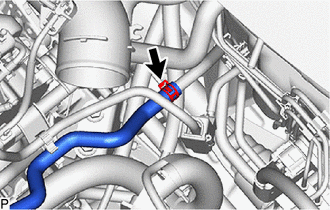

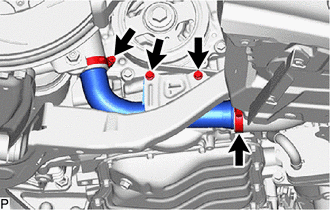

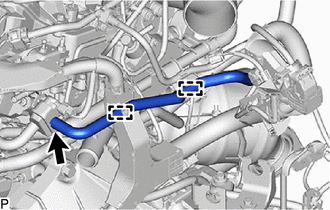

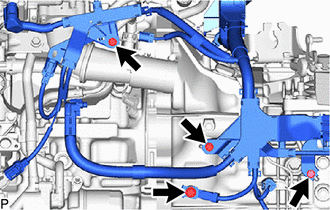

32. REMOVE NO. 1 WATER BY-PASS HOSE

| (a) Slide the clip and disconnect the No. 1 water by-pass hose from the No. 4 water by-pass pipe. |

|

33. REMOVE NO. 2 WATER BY-PASS HOSE

| (a) Slide the clip and disconnect the No. 2 water by-pass hose from the No. 4 water by-pass pipe. |

|

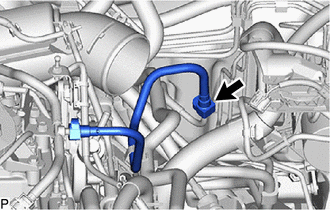

34. DISCONNECT NO. 1 FUEL VAPOR FEED HOSE

| (a) Slide the clip and disconnect the No. 1 fuel vapor hose from the fuel tank to canister tube. |

|

35. DISCONNECT OUTLET HEATER WATER HOSE

Click here

36. DISCONNECT INLET HEATER WATER HOSE

Click here

37. DISCONNECT FUEL TUBE SUB-ASSEMBLY

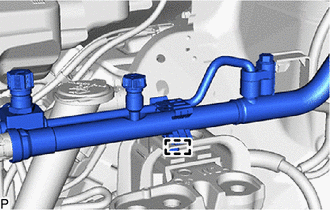

| (a) Remove the No. 1 fuel pipe clamp for the fuel tube sub-assembly. |

|

| (b) Disconnect the fuel tube sub-assembly from the fuel pipe. Click here

|

|

38. DISCONNECT SUCTION HOSE SUB-ASSEMBLY

Click here

39. DISCONNECT NO. 1 COOLER REFRIGERANT DISCHARGE HOSE

Click here

40. SECURE STEERING WHEEL ASSEMBLY

Click here

41. REMOVE COLUMN HOLE COVER SILENCER SHEET

Click here

42. DISCONNECT NO. 2 STEERING INTERMEDIATE SHAFT ASSEMBLY

Click here

43. REMOVE FRONT DRIVE SHAFT ASSEMBLY

Click here

44. DISCONNECT NO. 1 CLUTCH HOSE

| (a) Using a 10 mm union nut wrench, disconnect the bleeder clutch release tube from the No. 1 clutch hose. |

|

(b) Remove the clip and disconnect the No. 1 clutch hose from the clutch flexible hose bracket.

45. REMOVE NO. 1 AIR TUBE

| (a) Remove tha 2 bolts. |

|

(b) Lossen the 2 hose clamps and remove the No. 1 air tube.

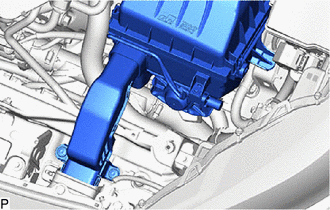

46. REMOVE ENGINE ASSEMBLY WITH TRANSAXLE

(a) Set the engine assembly with transaxle on an engine lifter.

NOTICE:

- Using height adjustment attachments and plate lift attachments, keep the engine assembly with transaxle and front suspension crossmember sub-assembly level.

- Do not perform any procedures while the engine assembly is suspended because doing so may cause the engine assembly to drop, resulting in injury. However, the engine assembly needs to be suspended when it is installed to or removed from an engine stand.

- To prevent the engine assembly from unexpectedly moving, securely support the engine assembly until it is secured to an engine stand.

- To prevent the oil pan sub-assembly from deforming, do not place any attachments under the oil pan sub-assembly of the engine assembly with transaxle.

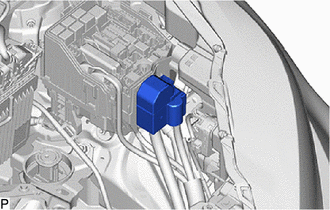

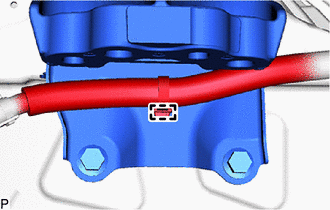

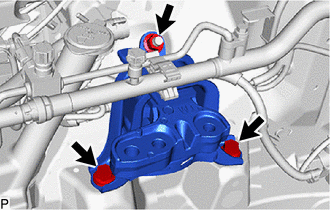

| (b) Remove the 3 bolts and separate the engine mounting insulator sub-assembly RH from the engine mounting bracket RH. |

|

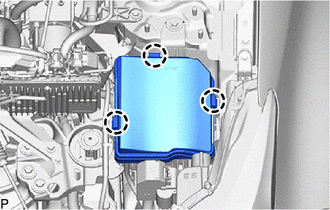

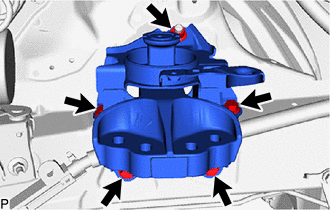

| (c) Remove the 4 bolts and separate the engine mounting insulator LH from the hybrid vehicle transaxle assembly. |

|

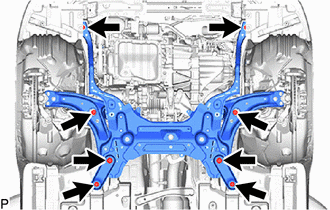

| (d) Remove the 8 bolts to separate the front suspension crossmember sub-assembly from the vehicle. |

|

(e) Operate the engine lifter and remove the engine assembly with transaxle from the vehicle.

NOTICE:

- Make sure that the engine assembly with transaxle is clear of all wiring and hoses.

- While lowering the engine assembly with transaxle from the vehicle, do not allow it to contact the vehicle.

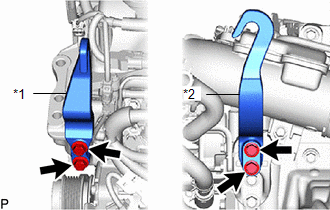

47. INSTALL ENGINE HANGERS

(a) Install the No. 1 engine hanger and No. 2 engine hanger with the 4 bolts as shown in the illustration.

| *1 | No. 1 Engine Hanger |

| *2 | No. 2 Engine Hanger |

| Bolt |

Torque:

43 N·m {438 kgf·cm, 32 ft·lbf}

| No. 1 Engine Hanger | 12281-25030 12281-25040 |

| No. 2 Engine Hanger | 12282-18010 12282-18020 |

| Bolt | 91552-F1045 91552-F1060 |

(b) Using an engine sling device and engine lift, secure the engine assembly with transaxle.

NOTICE:

- Pay attention to the angle of the sling device as the engine assembly or No. 1 engine hanger and No. 2 engine hanger may be damaged or deformed if the angle is incorrect.

- Do not perform any procedures while the engine assembly is suspended because doing so may cause the engine assembly to drop, resulting in injury. However, the engine assembly needs to be suspended when it is installed to or removed from an engine stand.

48. REMOVE ENGINE MOUNTING INSULATOR LH

HINT:

Perform this procedure only when replacement of the engine mounting insulator LH is necessary.

| (a) Disengage the clamp from the engine mounting insulator LH. |

|

| (b) Remove the 5 bolts, nut and engine mounting insulator LH from the vehicle. |

|

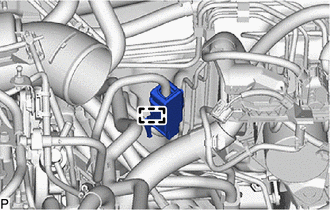

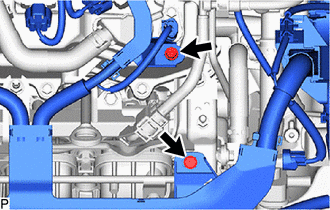

49. REMOVE RESERVE TANK ASSEMBLY

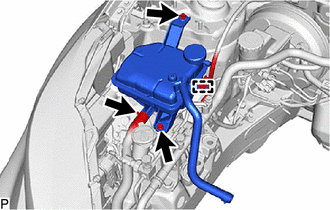

| (a) Slide the clip and remove the No.3 water by-pass hose from the reserve tank assy. |

|

(b) Disengage the clamp and remove the engine wire from the reserve tank assy.

(c) Remove the 2 bolts and remove the reserve tank assy from the vehicle.

50. REMOVE ENGINE MOUNTING INSULATOR SUB-ASSEMBLY RH

HINT:

Perform this procedure only when replacement of the engine mounting insulator sub-assembly RH is necessary.

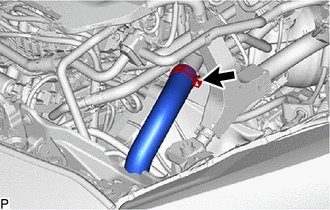

| (a) Remove the clamp and disconnect the air conditioner tube. |

|

| (b) Remove the 2 bolts, nut and engine mounting insulator sub-assembly RH from the vehicle. |

|

51. REMOVE NO. 1 FUEL VAPOR FEED HOSE

| (a) Disengage the 2 clamps from the engine assembly with transaxle. |

|

(b) Slide the clip and remove the No. 1 fuel vapor feed hose from the engine assembly with transaxle.

52. REMOVE STARTER ASSEMBLY

Click here

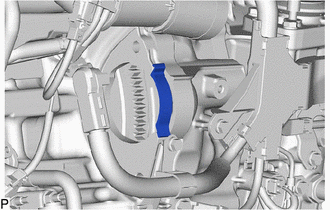

53. REMOVE FLYWHEEL HOUSING SIDE COVER

| (a) Remove the flywheel housing side cover from the cylinder block sub-assembly. |

|

54. REMOVE FAN AND GENERATOR V BELT

Click here

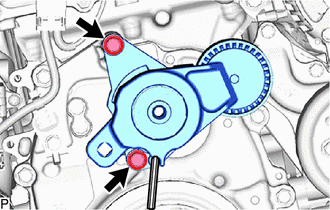

55. REMOVE V-RIBBED BELT TENSIONER ASSEMBLY

| (a) Remove the 2 bolts and V-ribbed belt tensioner assembly from the timing chain cover assembly. |

|

56. REMOVE GENERATOR WITH REGULATOR ASSEMBLY

Click here

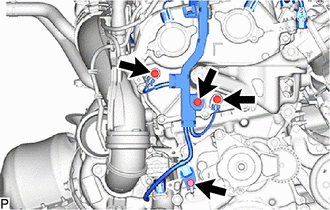

57. REMOVE ENGINE WIRE

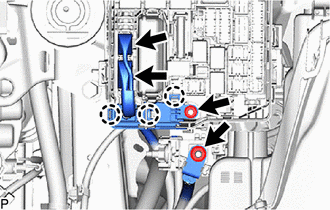

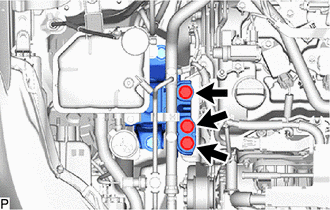

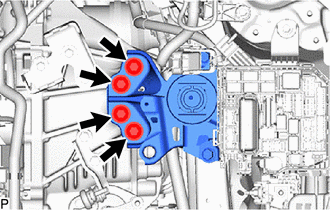

| (a) Remove the 4 bolts. |

|

| (b) Remove the 4 bolts. |

|

(c) Remove the 2 bolts.

| (d) Remove the 2 bolts. |

|

(e) Disconnect all the clamps and connectors and remove the engine wire from the engine assembly with transaxle.

58. REMOVE EXHAUST MANIFOLD CONVERTER SUB-ASSEMBLY

Click here

59. REMOVE PROPELLER SHAFT HEAT INSULATOR

Click here

60. REMOVE MANUAL TRANSAXLE ASSEMBLY

Click here

61. REMOVE COVER AND DISC CLUTCH SET

Click here

62. REMOVE FLYWHEEL SUB-ASSEMBLY

Click here

63. REMOVE NO. 1 CRANKSHAFT POSITION SENSOR PLATE

Click here

64. INSTALL ENGINE ASSEMBLY TO ENGINE STAND

(a) Install the engine assembly to an engine stand.

65. REMOVE ENGINE HANGERS

(a) Remove the 4 bolts, No. 1 engine hanger and No. 2 engine hanger.

Components

Components

COMPONENTS ILLUSTRATION

*1 NO. 1 ENGINE UNDER COVER ASSEMBLY *2 ENGINE UNDER COVER RH *3 ENGINE UNDER COVER LH *4 CENTER NO. 4 ENGINE UNDER COVER

N*m (kgf*cm, ft...

Installation

Installation

INSTALLATION CAUTION / NOTICE / HINT CAUTION: The engine assembly with transaxle is very heavy. Be sure to follow the procedure described in the repair manual, or the engine lifter may suddenly drop...

Other information:

Toyota Yaris XP210 (2020-2026) Owner's Manual: Outside the United States/Canada

Government regulations in the United States/Canada require that automobiles meet specific emission regulations and safety standards. Therefore, vehicles built for use in the United States/Canada may differ from those sold in other countries. The differences may make it difficult or even impossible for your vehicle to receive satisfactory servicing in other countries...

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Air Inlet Damper Control Servo Motor Actuator Stuck Off (B143B7F)

DESCRIPTION The No. 1 blower damper servo sub-assembly sends pulse signals to inform the air conditioning amplifier assembly of the damper position. The air conditioning amplifier assembly activates the motor (normal or reverse) based on these signals to move the air inlet damper to the appropriate position, which controls the air inlet switching...

Categories

- Manuals Home

- Toyota Yaris Owners Manual

- Toyota Yaris Service Manual

- Opening and Closing the Liftgate/Trunk Lid

- Fuel Gauge

- Diagnostic Trouble Code Chart

- New on site

- Most important about car

Turning the Engine Off

Stop the vehicle completely. Manual transaxle: Shift into neutral and set the parking brake.Automatic transaxle: Shift the selector lever to the P position and set the parking brake.

Press the push button start to turn off the engine. The ignition position is off.