Toyota Yaris: Pre-collision System / Utility

UTILITY

NOTICE:

If any of the following parts have been replaced, perform beam/optical axis learning. Otherwise all systems that use the parts may be affected.

-

Millimeter Wave Radar Sensor Assembly:

HINT:

Beam axis alignment of the millimeter wave radar sensor assembly can be performed using either Triangle Target, Flat Surface Target or Driving Adjustment.

Triangle Target: Click here

Flat Surface Target: Click here

Driving Adjustment: Click here

-

Forward Recognition Camera:

HINT:

Forward recognition camera axis alignment can be performed by using either One Time Recognition, Sequential Recognition or Driving Adjustment.

One Time Recognition: Click here

Sequential Recognition: Click here

Driving Adjustment: Click here

Initialization

Initialization

INITIALIZATION STEERING SENSOR ZERO POINT CALIBRATION (a) Start the engine. (b) Drive the vehicle straight ahead at 35 km/h (22 mph) or more for 5 seconds or more...

Problem Symptoms Table

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE NOTICE: When replacing the combination meter assembly, always replace it with a new one. If a combination meter assembly which was installed to another vehicle is used, the information stored in it will not match the information from the vehicle and a DTC may be stored...

Other information:

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Components

C..

Toyota Yaris XP210 (2020-2026) Owner's Manual: Outside Mirrors

Mirror type Flat type (driver’s side) Flat surface mirror. Convex type (front passenger side) The mirror has single curvature on its surface. Power mirror adjustment The ignition must be switched to ACC or ON position. To adjust: Rotate the mirror switch to the left or right to choose the left or right side mirror...

Categories

- Manuals Home

- Toyota Yaris Owners Manual

- Toyota Yaris Service Manual

- Battery Monitor Module General Electrical Failure (P058A01)

- Headlights

- How to connect USB port/Auxiliary jack

- New on site

- Most important about car

Refueling

Before refueling, close all the doors, windows, and the liftgate/trunk lid, and switch the ignition OFF.

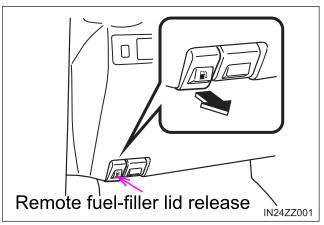

To open the fuel-filler lid, pull the remote fuel-filler lid release.