Toyota Yaris: Stop And Start System / Terminals Of Ecu

TERMINALS OF ECU

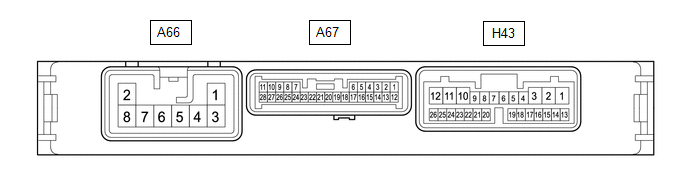

ENGINE STOP AND START ECU

(a) Disconnect the engine stop and start ECU connectors.

(b) Measure the resistance and voltage according to the value(s) in the table below.

| Play at SpinBet for top online casino games and bonuses in New Zealand Terminal No. (Symbol) | Terminal Description | Condition | Specified Condition |

|---|---|---|---|

| A66-1 (BIN2) - Body ground | Auxiliary battery | Always | 9.5 to 14 V |

| A66-2 (GND2) - Body ground | Ground | Always | Below 1 Ω |

| A66-3 (BIN1) - Body ground | Auxiliary battery | Always | 9.5 to 14 V |

| A66-8 (GND1) - Body ground | Ground | Always | Below 1 Ω |

| A67-1 (+B) - Body ground | Power source of engine stop and start ECU | Ignition switch ON | 9.5 to 14 V |

| A67-6 (DGND) - Body ground | Ground | Always | Below 1 Ω |

| A67-10 (NE) - Body ground | Engine speed signal from ECM | Always | Pulse generation (see waveform 1) |

| H43-13 (CANH) - Body ground | CAN communication | Always | 200 Ω or higher |

| H43-14 (CANL) - Body ground | CAN communication | Always | 200 Ω or higher |

| H43-15 (LC1H) - Body round | Local bus communication line | Always | 200 Ω or higher |

| H43-16 (LC1L) - Body round | Local bus communication line | Always | 200 Ω or higher |

| H43-18 (IGP) - Body ground | Ignition switch signal | Ignition switch ON | 9.5 to 14 V |

| H43-19 (ACC) - Body ground | Ignition switch signal | Ignition switch ACC | 9.5 to 14 V |

| H43-21 (IGR) - Body ground | Ignition switch signal | Ignition switch ON | 9.5 to 14 V |

(c) Reconnect the engine stop and start ECU connectors.

(d) Measure the resistance, voltage and pulse according to the value(s) in the table below.

| Terminal No. (Symbol) | Terminal Description | Condition | Specified Condition |

|---|---|---|---|

| A67-3 (BRE2) - Body ground | Ground (vacuum sensor assembly) | Always | Below 1 Ω |

| A67-7 (BNT1) - A67-6 (DGND) | Engine hood courtesy switch (hood lock assembly) signal |

| Below 1.5 V |

| 8 to 14 V | ||

| A67-8 (TMN) - A67-25 (TME2) | Neutral position switch signal |

| 2.7 to 4.3 V |

| 0.7 to 1.9 V | ||

| A67-10 (NE) - A67-6 (DGND) | Engine speed signal from ECM | Idling after engine warmed up | Pulse generation (See waveform 1) |

| A67-13 (PB) - A67-3 (BRE2) | Vacuum sensor assembly signal |

| 1.6 to 2.0 V |

| 2.2 to 2.6 V | ||

| 3.4 to 3.8 V | ||

| A67-14 (BRVC) - A67-6 (DGND) | Vacuum sensor assembly power supply |

| 4.5 to 5.5 V |

| A67-17 (CLL) - A67-6 (DGND) | Clutch switch assembly signal |

| 8 to 14 V |

| Below 1.5 V | ||

| A67-19 (DON2) - A67-6 (DGND) | External backup boost converter (eco run vehicle converter assembly) signal | Engine running | Pulse generation (See waveform 2) |

| A67-21 (STA) - A67-6 (DGND) | Starter pinion operation signal | Cranking | 6.0 V or more |

| A67-26 (TMVC) - A67-6 (DGND) | Neutral position switch power supply |

| 4.5 to 5.5 V |

| H43-23 (IG31) - A67-6 (DGND) | Backup boost converter signal | Ignition switch ON | 10.5 to 16 V |

| H43-3 (IG41) - A67-6 (DGND) | Backup boost converter signal | Ignition switch ON | 10.5 to 16 V |

| H43-5 (ECAN) - A67-6 (DGND) | Stop and start system cancel switch (combination switch assembly) signal |

| Below 1.5 V |

| 8 to 14 V | ||

| H43-10 (IG12) - A67-6 (DGND) | Backup boost converter signal | Ignition switch ON | 10.5 to 16 V |

| H43-11 (B43) - A67-6 (DGND) | Backup boost converter signal | Always | 10.5 to 16 V |

| H43-18 (IGP) - A67-6 (DGND) | Ignition switch signal | Ignition switch ACC | Below 1 V |

| Ignition switch ON | 9.5 to 14 V | ||

| H43-19 (ACC) - A67-6 (DGND) | Ignition switch signal | Ignition switch off | Below 1 V |

| Ignition switch ACC | 9.5 to 14 V | ||

| H43-21 (IGR) - A67-6 (DGND) | Ignition switch signal | Ignition switch ACC | Below 1 V |

| Ignition switch ON | 9.5 to 14 V | ||

| H43-23 (IG31) - A67-6 (DGND) | Backup boost converter signal | Ignition switch ON | 10.5 to 16 V |

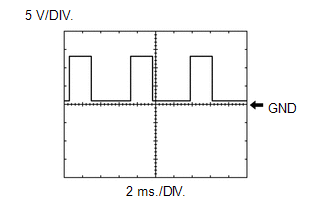

(e) Waveform 1

| Item | Content |

|---|---|

| Tester Connection | A67-10 (NE) - A67-6 (DGND) |

| Tool Setting | 5 V/DIV., 2 ms./DIV. |

| Condition | Idling after engine warmed up |

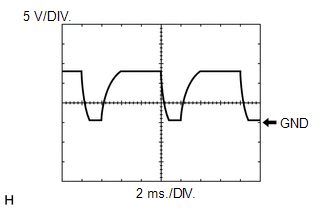

(f) Waveform 2

| Item | Content |

|---|---|

| Tester Connection | A67-19 (DON2) - A67-6 (DGND) |

| Tool Setting | 5 V/DIV., 2 ms./DIV. |

| Condition | Engine running |

Problem Symptoms Table

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE Stop and Start System Symptom Suspected Area Link Stop and start system does not operate Refer to "Stop and Start System does not Operate"

Refer to "Stop and Start System does not Operate (Battery Condition)"

Restarting after a short period of time from an idling stop Refer to "Restarting after a Short Period of Time from an Idling Stop"

After engine stops due to stop and start system, engine does not restart Refer to "After Engine Stops due to Stop and Start System, Engine does not Restart"

Failure to restart from IG-ON engine stall Refer to "Failure to Restart from IG-ON Engine Stall"

Stop and start cancel indicator does not operate Combination meter assembly

Indicator circuit (CAN communication system)

Engine stop and start ECU

Stop and start indicator does not operate Combination meter assembly

Indicator circuit (CAN communication system)

Engine stop and start ECU

Stop and start control cannot be canceled ECAN terminal voltage

Stop and start cancel switch circuit

Multi-information display screen does not change after pressing steering pad switch assembly...

Diagnosis System

Diagnosis System

DIAGNOSIS SYSTEM DESCRIPTION When troubleshooting a vehicle with a diagnosis system, the only difference from the usual troubleshooting procedure is connecting the GTS to the vehicle and reading various data output from the engine stop and start ECU...

Other information:

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Removal

REMOVAL CAUTION / NOTICE / HINT The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed, installed, or replaced during the curtain shield airbag assembly removal/installation are shown below...

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Inspection

INSPECTION PROCEDURE 1. INSPECT FRONT DRIVE SHAFT ASSEMBLY (a) Check that there is no excessive play in the radial direction of the outboard joint. (b) Check that the inboard joint slides smoothly in the thrust direction. (c) Check that there is no excessive play in the radial direction of the inboard joint...

Categories

- Manuals Home

- Toyota Yaris Owners Manual

- Toyota Yaris Service Manual

- Opening and Closing the Liftgate/Trunk Lid

- G16e-gts (engine Mechanical)

- How to use USB mode

- New on site

- Most important about car

Front Seat Belt Pretensioners

The front seat belt pretensioners are designed to deploy in moderate or severe frontal, near frontal collisions.

In addition, the pretensioners operate when a side collision or a rollover accident is detected. The pretensioners operate differently depending on what types of air bags are equipped. For more details about the seat belt pretensioner operation, refer to the SRS Air Bag Deployment Criteria.