Toyota Yaris: Shift And Select Lever Shaft / Disassembly

DISASSEMBLY

PROCEDURE

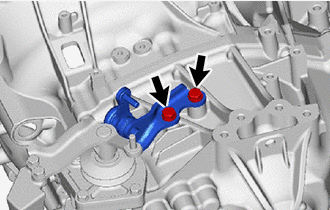

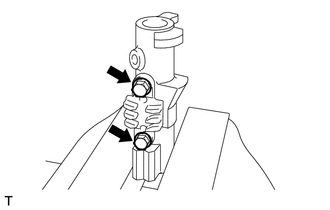

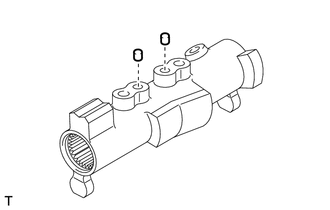

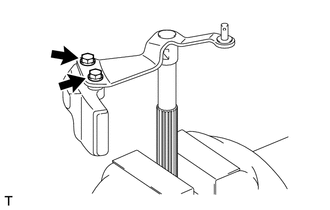

1. REMOVE SELECTING BELL CRANK ASSEMBLY

| (a) Remove the 2 bolts and selecting bell crank assembly from the manual transmission case. |

|

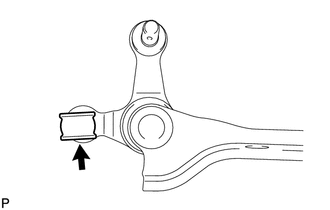

2. REMOVE CONTROL SHIFT LEVER BUSHING

| (a) Remove the control shift lever bushing from the selecting bell crank assembly. |

|

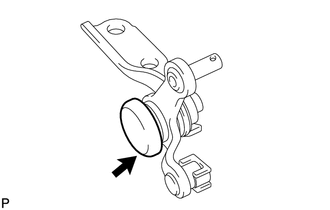

3. REMOVE NO. 1 SELECTING BELL CRANK DUST COVER

| (a) Remove the No. 1 selecting bell crank dust cover from the selecting bell crank assembly. |

|

4. REMOVE BACK-UP LIGHT SWITCH ASSEMBLY

Click here

5. REMOVE NEUTRAL POSITION SWITCH

Click here

6. REMOVE NO. 1 LOCK BALL ASSEMBLY

Click here

7. REMOVE NO. 2 LOCK BALL ASSEMBLY

Click here

8. REMOVE SHIFT GATE PIN

Click here

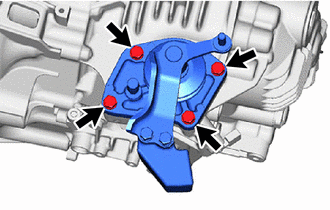

9. REMOVE SHIFT AND SELECT LEVER ASSEMBLY

| (a) Remove the 4 bolts and shift and select lever assembly from the manual transmission case. |

|

10. REMOVE NO. 1 SHIFT LEVER INNER

| (a) Using a pin punch and hammer, remove the slotted spring pin from the No. 1 shift lever inner. |

|

| (b) Remove the No. 1 shift lever inner and shift interlock plate from the shift and select lever shaft. |

|

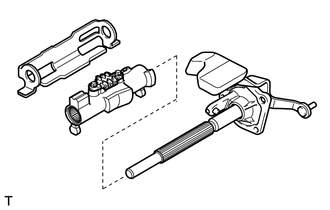

11. REMOVE SHIFT AND SELECT LEVER SHAFT

| (a) Remove the control shaft cover and the shift and select lever boot from the shift and select lever shaft. |

|

12. REMOVE SHIFT GATE PLATE

| (a) Remove the 2 bolts and shift gate plate from the No. 1 shift lever inner. |

|

13. REMOVE PIN

| (a) Remove the 2 pins from the No. 1 shift lever inner. |

|

14. REMOVE SHIFT LEVER DAMPER

| (a) Remove the 2 bolts and shift lever damper from the shift lever shaft. |

|

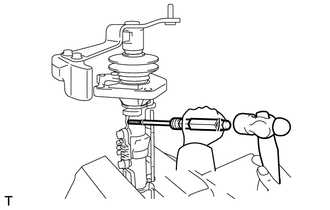

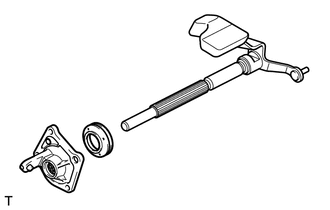

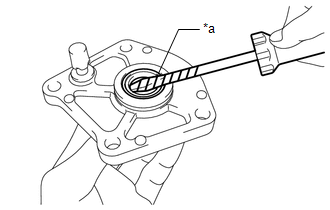

15. REMOVE CONTROL SHAFT COVER OIL SEAL

| (a) Using a screwdriver with its tip wrapped with protective tape, remove the control shaft cover oil seal from the control shaft cover. |

|

Components

Components

COMPONENTS ILLUSTRATION

*1 SHIFT AND SELECT LEVER ASSEMBLY *2 NO. 1 SELECTING BELL CRANK DUST COVER *3 SELECTING BELL CRANK ASSEMBLY *4 CONTROL SHIFT LEVER BUSHING *5 SHIFT GATE PIN *6 NO...

Reassembly

Reassembly

REASSEMBLY PROCEDURE 1. INSTALL CONTROL SHAFT COVER OIL SEAL (a) Using SST and a hammer, install a control shaft cover oil seal to the control shaft cover...

Other information:

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Stop And Start System Cancel Switch Assembly

ComponentsCOMPONENTS ILLUSTRATION *1 ECO RUN CANCEL SWITCH ASSEMBLY (COMBINATION SWITCH ASSEMBLY) - - RemovalREMOVAL PROCEDURE 1. REMOVE ECO RUN CANCEL SWITCH ASSEMBLY (COMBINATION SWITCH ASSEMBLY) Click here InspectionINSPECTION PROCEDURE 1...

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: A/F (O2) Sensor Positive Current Control Bank 1 Sensor 2 Circuit Short to Ground (P22AB11,P22AB12,P22AB13,P22AB16,P22AB17,P22B211,P22B212)

DESCRIPTION Refer to DTC P003612. Click here DTC No. Detection Item DTC Detection Condition Trouble Area MIL Note P22AB11 A/F (O2) Sensor Positive Current Control Bank 1 Sensor 2 Circuit Short to Ground The A1B+ voltage is 1.43 V or less for 5 seconds or more (2 trip detection logic)...

Categories

- Manuals Home

- Toyota Yaris Owners Manual

- Toyota Yaris Service Manual

- Brake System Control Module "A" System Voltage System Voltage Low (C137BA2)

- To Set Speed

- Removal

- New on site

- Most important about car

Fuel Gauge

The fuel gauge shows approximately how much fuel is remaining in the tank when the ignition is switched ON. We recommend keeping the tank over 1/4 full.