Toyota Yaris: Charging System / Charging Failure

PROCEDURE

| 1. | CHECK GENERATOR PULLEY WITH CLUTCH (ON-VEHICLE INSPECTION) |

(a) Start the engine and visually check that the generator rotor assembly (fan) in the generator assembly is operating.

OK:

The generator rotor assembly (fan) is operating.

| NG |

| REPLACE GENERATOR PULLEY WITH CLUTCH |

|

| 2. | CHECK GENERATOR PULLEY WITH CLUTCH (UNIT INSPECTION) |

(a) Remove the generator assembly.

Click here

(b) Check the installation condition of the generator pulley cap.

OK:

The generator pulley cap is not loose or missing.

(c) Check for forming of particles due to friction (for dry type pulley) or grease leaks (for wet type pulley).

OK:

There are no large amounts of particles (for dry type pulley) or grease leaks (for wet type pulley).

(d) Check the generator pulley with clutch for misalignment (interference with the generator assembly).

OK:

The generator pulley with clutch is not misaligned (no interference with the generator assembly).

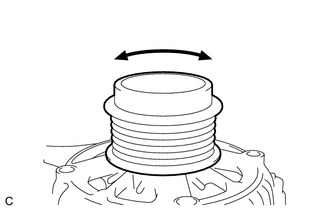

| (e) Turn the generator pulley with clutch clockwise and counterclockwise by hand and check for noise. OK: Noise does not occur when turned in either direction. |

|

(f) Turn the generator pulley with clutch clockwise and counterclockwise by hand and visually check for runout.

OK:

The generator pulley with clutch does not have runout.

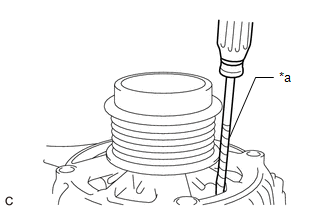

| (g) Hold the generator rotor assembly (fan) in the generator assembly with a screwdriver with its tip wrapped with protective tape, and check that the generator pulley with clutch locks when turned clockwise and turns freely when turned counterclockwise. OK: The generator pulley with clutch locks when turned clockwise and turns freely when turned counterclockwise. |

|

| OK |

| REPLACE GENERATOR ASSEMBLY |

| NG |

| REPLACE GENERATOR PULLEY WITH CLUTCH |

Lost Communication with Battery Monitor Module Missing Message (P162B87)

Lost Communication with Battery Monitor Module Missing Message (P162B87)

DESCRIPTION The ECM and battery state sensor assembly each detect reception malfunctions. A battery state sensor assembly reception malfunction detected by the battery state sensor assembly is sent to the ECM via LIN communication...

Noise Occurs from V-ribbed Belt or Generator Assembly

Noise Occurs from V-ribbed Belt or Generator Assembly

PROCEDURE 1. CONFIRM PROBLEM SYMPTOM (a) Confirm the problem symptom. Symptom Proceed to Noise occurs from V-ribbed belt A Noise occurs from generator assembly B B

GO TO STEP 6

A

2...

Other information:

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Driver Side Power Window does not Operate with Power Window Master Switch

DESCRIPTION When the ignition switch is ON, the power window regulator motor assembly (for driver door) is operated by the multiplex network master switch assembly. The power window regulator motor assembly (for driver door) has motor, regulator and ECU functions...

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Parts Location

PARTS LOCATION ILLUSTRATION *1 BRAKE MASTER CYLINDER RESERVOIR ASSEMBLY - BRAKE FLUID LEVEL WARNING SWITCH *2 THERMISTOR ASSEMBLY *3 ECM *4 BRAKE ACTUATOR ASSEMBLY - SKID CONTROL ECU ILLUSTRATION *1 HEADLIGHT ASSEMBLY RH *2 HEADLIGHT ASSEMBLY LH *3 HEADLIGHT UNIT ASSEMBLY RH *4 HEADLIGHT UNIT ASSEMBLY LH *5 HEADLIGHT CORD *6 OUTER REAR VIEW MIRROR ASSEMBLY RH - SIDE TURN SIGNAL LIGHT ASSEMBLY RH *7 OUTER REAR VIEW MIRROR ASSEMBLY LH - SIDE TURN SIGNAL LIGHT ASSEMBLY LH *8 REAR COMBINATION LIGHT ASSEMBLY RH *9 REAR COMBINATION LIGHT ASSEMBLY LH *10 REAR TURN SIGNAL LIGHT LED ILLUSTRATION *1 MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) *2 POWER DISTRIBUTION BOX ASSEMBLY - ECU-DCC NO...

Categories

- Manuals Home

- Toyota Yaris Owners Manual

- Toyota Yaris Service Manual

- Fuel Gauge

- Engine & Hybrid System

- Brake System Control Module "A" System Voltage System Voltage Low (C137BA2)

- New on site

- Most important about car

Fuel Gauge

The fuel gauge shows approximately how much fuel is remaining in the tank when the ignition is switched ON. We recommend keeping the tank over 1/4 full.