Toyota Yaris: Charging System / Noise Occurs from V-ribbed Belt or Generator Assembly

PROCEDURE

| 1. | CONFIRM PROBLEM SYMPTOM |

(a) Confirm the problem symptom.

| Symptom | Proceed to |

|---|---|

| Noise occurs from V-ribbed belt | A |

| Noise occurs from generator assembly | B |

| B |

| GO TO STEP 6 |

|

| 2. | CHECK FAN AND GENERATOR V BELT |

(a) Check the fan and generator V belt for wear or damage.

OK:

The fan and generator V belt is not worn or damaged.

| NG |

| REPLACE FAN AND GENERATOR V BELT |

|

| 3. | CHECK GENERATOR PULLEY WITH CLUTCH FOR WEAR |

(a) Check the generator pulley with clutch grooves for wear or damage.

OK:

The generator pulley with clutch grooves are not worn or damaged.

| NG |

| REPLACE GENERATOR PULLEY WITH CLUTCH |

|

| 4. | CHECK FOR NOISE WHILE CLUTCH PULLEY IS OPERATING |

(a) Start the engine and check the generator pulley with clutch for looseness.

OK:

The generator pulley with clutch is not loose.

| NG |

| TIGHTEN GENERATOR PULLEY WITH CLUTCH TO SPECIFIED TORQUE |

|

| 5. | INSPECT GENERATOR PULLEY WITH CLUTCH (UNIT INSPECTION) |

(a) Remove the generator assembly.

Click here

(b) Check the installation condition of the generator pulley cap.

OK:

The generator pulley cap is not loose or missing.

(c) Check for forming of particles due to friction (for dry type pulley) or grease leaks (for wet type pulley).

OK:

There are no large amounts of particles (for dry type pulley) or grease leaks (for wet type pulley).

(d) Check the generator pulley with clutch for misalignment (interference with the generator assembly).

OK:

The generator pulley with clutch is not misaligned (no interference with the generator assembly).

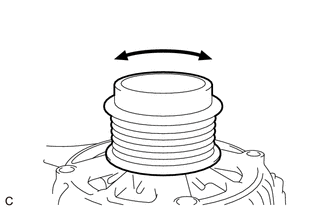

| (e) Turn the generator pulley with clutch clockwise and counterclockwise by hand and check for noise. OK: Noise does not occur when turned in either direction. |

|

(f) Turn the generator pulley with clutch clockwise and counterclockwise by hand and visually check for runout.

OK:

The generator pulley with clutch does not have runout.

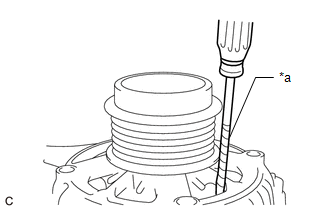

| (g) Hold the generator rotor assembly (fan) in the generator assembly with a screwdriver with its tip wrapped with protective tape, and check that the generator pulley with clutch locks when turned clockwise and turns freely when turned counterclockwise. OK: The generator pulley with clutch locks when turned clockwise and turns freely when turned counterclockwise. |

|

| OK |

| INSPECT PULLEY OTHER THAN GENERATOR ASSEMBLY PULLEY |

| NG |

| REPLACE GENERATOR PULLEY WITH CLUTCH |

| 6. | CHECK FOR NOISE WHEN ROTOR IS TURNING FREELY |

(a) Perform a road test and check that noise does not occur when decelerating.

OK:

Noise does not occur.

(b) Stop the engine and check that generator pulley with clutch noise does not occur as the engine stops.

OK:

Noise does not occur.

| NG |

| REPLACE GENERATOR PULLEY WITH CLUTCH |

|

| 7. | CHECK ENGAGEMENT OF GENERATOR PULLEY WITH CLUTCH |

(a) Remove the generator assembly.

Click here

(b) Hold the generator rotor assembly (fan) in the generator assembly with a screwdriver with its tip wrapped with protective tape, and check that the generator pulley with clutch locks when turned from counterclockwise (free turning direction) to clockwise (locking direction).

OK:

The generator pulley with clutch locks.

| OK |

| REPAIR OR REPLACE GENERATOR ASSEMBLY |

| NG |

| REPLACE GENERATOR PULLEY WITH CLUTCH |

Charging Failure

Charging Failure

PROCEDURE 1. CHECK GENERATOR PULLEY WITH CLUTCH (ON-VEHICLE INSPECTION) (a) Start the engine and visually check that the generator rotor assembly (fan) in the generator assembly is operating...

Generator

Generator

..

Other information:

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Millimeter Wave Radar Sensor Communication Stop Mode

DESCRIPTION Detection Item Symptom Trouble Area Millimeter Wave Radar Sensor Communication Stop Mode Communication stop for "Front Radar" is indicated on the "Communication Bus Check" screen of the GTS. Click here Millimeter wave radar sensor assembly branch line or connector Power source circuit of millimeter wave radar sensor assembly Millimeter wave radar sensor assembly ground circuit Millimeter wave radar sensor assembly WIRING DIAGRAM CAUTION / NOTICE / HINT CAUTION: When performing the confirmation driving pattern, obey all speed limits and traffic laws...

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Barometric Pressure - Turbocharger / Supercharger Boost Sensor "A" Signal Compare Failure (P00CF62)

DESCRIPTION At ignition switch to ON or during idling, the No. 2 turbo pressure sensor and the atmospheric pressure sensor built into the ECM are at atmospheric pressure and their outputs match. DTC No. Detection Item DTC Detection Condition Trouble Area MIL Note P00CF62 Barometric Pressure - Turbocharger / Supercharger Boost Sensor "A" Signal Compare Failure 15 kPa [2...

Categories

- Manuals Home

- Toyota Yaris Owners Manual

- Toyota Yaris Service Manual

- Immobilizer System

- Headlights

- Battery Monitor Module General Electrical Failure (P058A01)

- New on site

- Most important about car

Break-In Period

No special break-in is necessary, but a few precautions in the first 600 miles (1,000 km) may add to the performance, economy, and life of the vehicle.

Do not race the engine. Do not maintain one constant speed, either slow or fast, for a long period of time. Do not drive constantly at full-throttle or high engine rpm for extended periods of time. Avoid unnecessary hard stops. Avoid full-throttle starts.