Toyota Yaris: Vehicle Stability Control System / Brake System Control Module "A" System Voltage System Voltage Low (C137BA2)

DESCRIPTION

If a malfunction is detected in the power supply circuit, the skid control ECU (brake actuator assembly) stores this DTC and the fail-safe function prohibits ABS operation.

This DTC is stored when the +BS terminal voltage meets one of the DTC detection conditions due to a malfunction in the power supply or charging circuit such as the auxiliary battery or alternator circuit, etc.

The DTC is cleared when the +BS terminal voltage returns to normal.

| DTC No. | Detection Item | DTC Detection Condition | Trouble Area | DTC Output from |

|---|---|---|---|---|

| C137BA2 | Brake System Control Module "A" System Voltage System Voltage Low | Any of the following is detected:

|

| Brake |

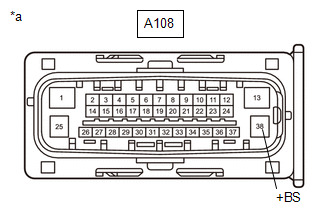

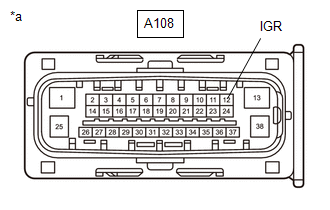

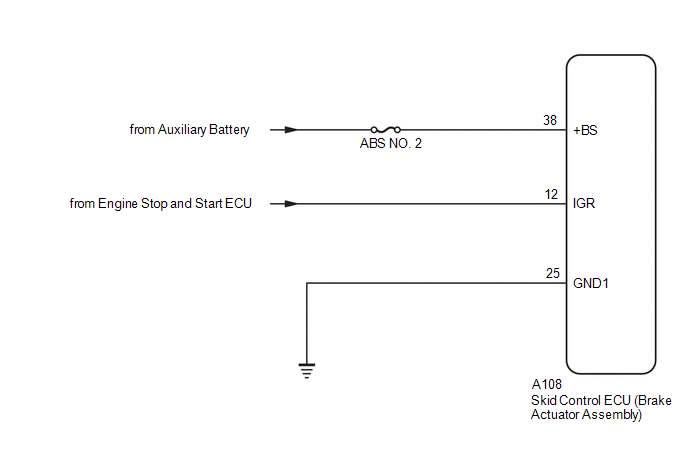

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- Inspect the fuses for circuits related to this system before performing the following procedure.

-

After replacing the skid control ECU (brake actuator assembly), perform "Calibration".

Click here

PROCEDURE

| 1. | CHECK AUXILIARY BATTERY |

(a) Check the auxiliary battery voltage.

Standard Voltage:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| Positive (+) auxiliary battery terminal - Negative (-) auxiliary battery terminal | Always | 11 to 14 V |

| NG |

| CHECK OR REPLACE CHARGING SYSTEM OR AUXILIARY BATTERY |

|

| 2. | CHECK HARNESS AND CONNECTOR (+BS TERMINAL) |

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors.

OK:

The connector is securely connected.

| (b) Disconnect the A108 skid control ECU (brake actuator assembly) connector. |

|

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| A108-38 (+BS) - Body ground | Always | 11 to 14 V |

| NG |

| REPAIR OR REPLACE HARNESS OR CONNECTOR (+BS CIRCUIT) |

|

| 3. | CHECK HARNESS AND CONNECTOR (IGR TERMINAL) |

(a) Turn the ignition switch to ON.

| (b) Measure the voltage according to the value(s) in the table below. Standard Voltage:

|

|

| NG |

| REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 4. | CHECK HARNESS AND CONNECTOR (GND1 TERMINAL) |

(a) Turn the ignition switch off.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| A108-25 (GND1) - Body ground | 1 minute or more after disconnecting the cable from the negative (-) auxiliary battery terminal | Below 1 Ω |

| NG |

| REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 5. | CLEAR DTC |

(a) Reconnect the A108 skid control ECU (brake actuator assembly) connector.

(b) Operate the GTS to clear the codes.

Chassis > Brake > Clear DTCs(c) Press the DTC clear button.

(d) Turn the ignition switch off.

|

| 6. | RECONFIRM DTC |

(a) Based on the Freeze Frame Data and interview with the customer, attempt to reproduce the conditions when the malfunction occurred.

(b) Operate the GTS to read the DTCs.

Chassis > Brake > Trouble Codes(c) Check if the same DTC is output.

| Result | Proceed to |

|---|---|

| C137BA2 is not output | A |

| C137BA2 is output | B |

| A |

| USE SIMULATION METHOD TO CHECK |

| B |

| REPLACE BRAKE ACTUATOR ASSEMBLY |

ECM Communication (C124A00)

ECM Communication (C124A00)

DESCRIPTION DTC No. Detection Item DTC Detection Condition Trouble Area DTC Output from C124A00 ECM Communication Any of the following is detected:

The engine type, powertrain variation, engine stop and start ECU availability and destination information sent from the ECM do not match the information stored in the skid control ECU (brake actuator assembly)...

Brake System Control Module "A" System Voltage System Voltage High (C137BA3)

Brake System Control Module "A" System Voltage System Voltage High (C137BA3)

DESCRIPTION If a malfunction is detected in the power supply circuit, the skid control ECU (brake actuator assembly) stores this DTC and the fail-safe function prohibits ABS operation...

Other information:

Toyota Yaris XP210 (2020-2025) Reapir and Service Manual: Security Indicator Light Does not Blink

DESCRIPTION The certification ECU (smart key ECU assembly) blinks the security indicator light (combination meter assembly) when the immobiliser is set (engine switch off). The certification ECU (smart key ECU assembly) receives the security indicator light signal from the main body ECU (multiplex network body ECU) via CAN communication when the theft deterrent system is in the arming preparation state or alarm sounding state...

Toyota Yaris XP210 (2020-2025) Reapir and Service Manual: Removal

REMOVAL CAUTION / NOTICE / HINT HINT: Use the same procedure for the RH side and LH side. The following procedure is for the LH side. If the rear speed sensor rotor needs to be replaced, replace the rear axle hub and bearing assembly. PROCEDURE 1...

Categories

- Manuals Home

- Toyota Yaris Owners Manual

- Toyota Yaris Service Manual

- Removal

- Adjustment

- Engine & Hybrid System

- New on site

- Most important about car

Liftgate/Trunk Lid

WARNING

Never allow a person to ride in the luggage compartment/trunk

Allowing a person to ride in the luggage compartment/trunk is dangerous. The person in the luggage compartment/trunk could be seriously injured or killed during sudden braking or a collision.

Do not drive with the liftgate/trunk lid open