Toyota Yaris: Air Fuel Ratio Sensor (for Sensor 1) / Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed, installed, or replaced during the air fuel ratio sensor removal/installation are shown below.

Necessary Procedure After Parts Removed/Installed/Replaced| Replacement Part or Procedure | Necessary Procedure | Effect/Inoperative when not Performed | Link |

|---|---|---|---|

| Inspection after repair |

|

|

CAUTION:

-

When the engine is hot, do not touch high-temperature areas such as the engine or exhaust manifold.

- Touching high-temperature areas such as the engine and exhaust manifold could result in burns.

PROCEDURE

1. REMOVE WINDSHIELD WIPER MOTOR AND LINK

Click here

2. REMOVE FRONT NO. 1 VENTILATOR SEAL

Click here

3. REMOVE WATER GUARD PLATE RH

Click here

4. REMOVE OUTER COWL TOP PANEL SUB-ASSEMBLY

Click here

5. SEPARATE NO. 1 AIR CLEANER HOSE

Click here

6. REMOVE INTAKE AIR RESONATOR

Click here

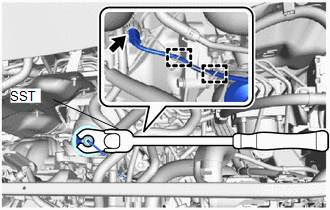

7. REMOVE AIR FUEL RATIO SENSOR

| (a) Disconnect the air fuel ratio sensor connector. |

|

(b) Disengage the 2 clamps.

(c) Using SST, remove the air fuel ratio sensor from the exhaust manifold.

SST: 09224-00012

NOTICE:

If the air fuel ratio sensor has been struck or dropped, replace it.

Components

Components

COMPONENTS ILLUSTRATION

*1 WATER GUARD PLATE LH *2 NO. 1 FRONT VENTILATOR SEAL *3 OUTER COWL TOP PANEL SUB-ASSEMBLY - -

N*m (kgf*cm, ft...

Inspection

Inspection

INSPECTION PROCEDURE 1. INSPECT AIR FUEL RATIO SENSOR (a) Measure the resistance according to the value(s) in the table below. Standard Resistance: Tester Connection Condition Specified Condition D102-1(HA1A) - D102-2(+B) 20°C (68°F) 1...

Other information:

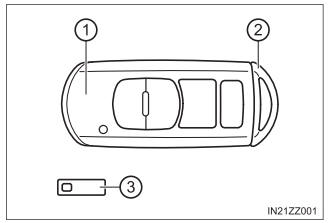

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Back Door Entry Lock and Unlock Functions do not Operate

DESCRIPTION If the entry lock and unlock functions do not operate for the back door only, the request code may not be being transmitted from the back door. If the entry functions for other doors operate properly, communication between the electrical key transmitter sub-assembly and the smart door control receiver assembly is normal...

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Internal Control Module Software Incompatibility Not Programmed (U030051,U030057)

DESCRIPTION The forward recognition camera receives vehicle information from the ECM via CAN communication. DTC U030051 is stored when the vehicle information from the ECM cannot be confirmed. The forward recognition camera receives the vehicle information from the ECM via CAN communication...

Categories

- Manuals Home

- Toyota Yaris Owners Manual

- Toyota Yaris Service Manual

- Key Battery Replacement

- Battery Monitor Module General Electrical Failure (P058A01)

- Immobilizer System

- New on site

- Most important about car

Keys

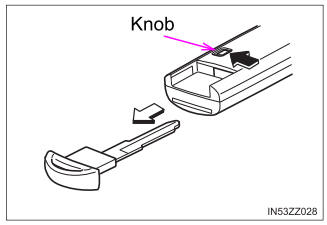

To use the auxiliary key, press the knob and pull out the auxiliary key from the smart key.