Toyota Yaris: Differential Case / Reassembly

REASSEMBLY

PROCEDURE

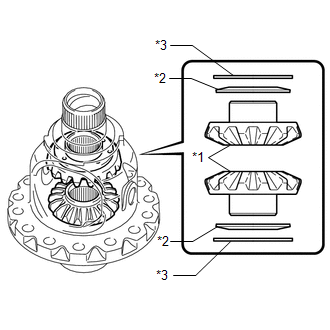

1. INSTALL FRONT DIFFERENTIAL SIDE GEAR (w/o LSD)

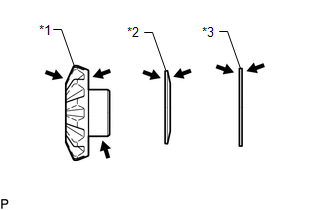

(a) Coat the front differential side gear, front No. 1 differential side gear thrust washer and conical spring with gear oil.

| *1 | Front Differential Side Gear |

| *2 | Conical Spring |

| *3 | Front No. 1 Differential Side Gear Thrust Washer |

| Gear Oil |

| (b) Install the 2 front differential side gears, 2 front No. 1 differential side gear thrust washers and 2 conical springs to the front No. 1 differential case sub-assembly. NOTICE:

|

|

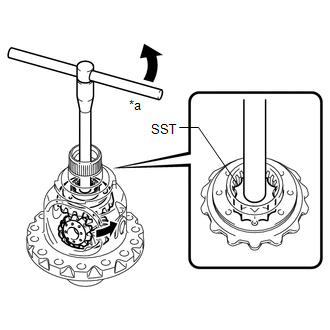

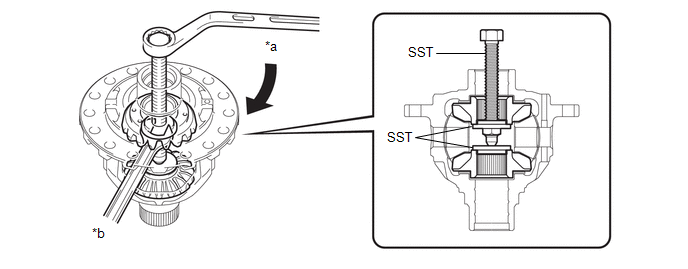

(c) Set SST as shown in the illustration and tighten it.

| *a | Turn | *b | Hold |

SST: 09528-52010

09528-05010

09953-05010

NOTICE:

Do not overtighten SST, as doing so will damage the front differential side gear, conical spring, front No. 1 differential side gear thrust washer and front No. 1 differential case sub-assembly.

HINT:

- Tighten SST to create the necessary clearance to install the front differential pinions.

- When installing the front differential pinions, do not overtighten SST, as it is necessary to rotate the front differential side gears.

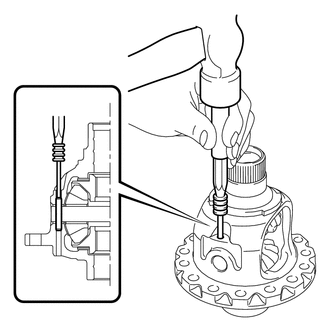

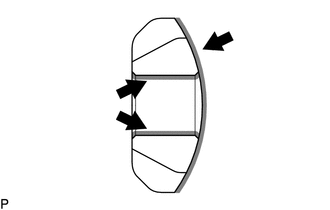

(d) Coat the front differential pinion and front differential pinion thrust washer with gear oil.

| Gear Oil |

| (e) Using SST as shown in the illustration, rotate the front differential side gear and install the 2 front differential pinions and 2 front differential pinion thrust washers. SST: 09528-52010 09528-05030 CAUTION: Be careful not to catch your fingers between the front differential pinion and front No. 1 differential case sub-assembly. NOTICE: Do not drop the front differential pinion and front differential pinion thrust washer. |

|

2. INSPECT FRONT DIFFERENTIAL PINION BACKLASH (w/o LSD)

Click here

3. INSTALL FRONT NO. 1 DIFFERENTIAL PINION SHAFT (w/o LSD)

(a) Coat a front No. 1 differential pinion shaft with gear oil.

| Gear Oil |

(b) Install the front No. 1 differential pinion shaft to the front No. 1 differential case sub-assembly so that the hole for the front differential pinion shaft straight pin is aligned with the hole in the front No. 1 differential case sub-assembly.

4. INSPECT FRONT NO. 1 DIFFERENTIAL CASE SUB-ASSEMBLY (w/o LSD)

Click here

5. INSTALL FRONT DIFFERENTIAL PINION SHAFT STRAIGHT PIN (w/o LSD)

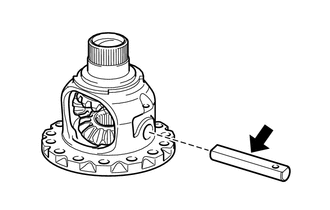

| (a) Using a 5 mm pin punch and hammer, install the front differential pinion shaft straight pin to the front No. 1 differential case sub-assembly. |

|

| (b) Using a chisel and hammer, stake the front No. 1 differential case sub-assembly. |

|

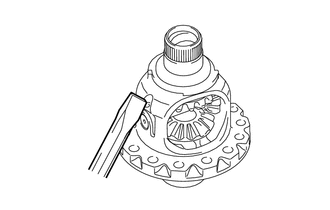

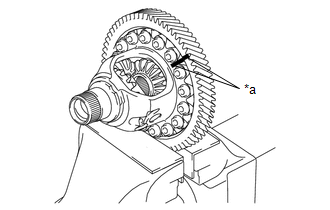

6. INSTALL FRONT DIFFERENTIAL RING GEAR

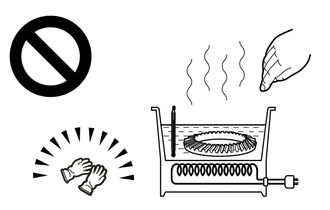

(a) Using a heater, heat the front differential ring gear to 90 to 100°C (194 to 212°F).

CAUTION:

Use thick gloves to protect your hands as the front differential ring gear is hot.

(b) Clean the contact surface of the front No. 1 differential case sub-assembly and front differential ring gear.

| (c) While aligning the matchmarks, quickly install the front differential ring gear to the front No. 1 differential case sub-assembly with the 16 bolts. Torque: 106 N·m {1081 kgf·cm, 78 ft·lbf} |

|

Inspection

Inspection

INSPECTION PROCEDURE 1. INSPECT FRONT NO. 1 DIFFERENTIAL CASE SUB-ASSEMBLY (a) Using SST, rotate the front differential side gear as shown in the illustration...

Differential Oil Seal (for Lh Side)

Differential Oil Seal (for Lh Side)

ComponentsCOMPONENTS ILLUSTRATION

*1 FRONT DRIVE SHAFT OIL SEAL LH - - ● Non-reusable part

MP grease ReplacementREPLACEMENT CAUTION / NOTICE / HINT The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during the front drive shaft oil seal LH removal/installation are shown below...

Other information:

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Terminals Of Ecu

TERMINALS OF ECU NOTICE: After the ignition switch is turned off, there may be a waiting time before disconnecting the negative (-) auxiliary battery terminal. Click here When disconnecting and reconnecting the auxiliary battery, there is an automatic learning function that completes learning when the respective system is used...

Toyota Yaris XP210 (2020-2026) Owner's Manual: Installing Child-Restraint Systems

Accident statistics reveal that a child is safer in the rear seat. The front passenger’s seat is clearly the worst choice for any child under 12, and with rear-facing child-restraint systems it is clearly unsafe due to air bags. Some child-restraint systems now come with tethers and therefore must be installed on the seats that take tethers to be effective...

Categories

- Manuals Home

- Toyota Yaris Owners Manual

- Toyota Yaris Service Manual

- Opening and Closing the Liftgate/Trunk Lid

- How to use USB mode

- Engine & Hybrid System

- New on site

- Most important about car

Key Suspend Function

If a key is left in the vehicle, the functions of the key left in the vehicle are temporarily suspended to prevent theft of the vehicle.

To restore the functions, press the unlock button on the functions-suspended key in the vehicle.