Toyota Yaris: Input Shaft / Reassembly

REASSEMBLY

PROCEDURE

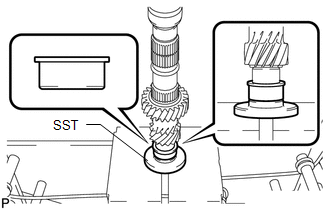

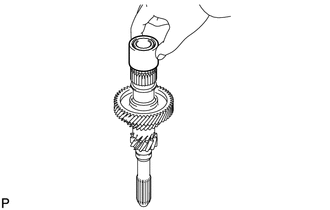

1. INSTALL INPUT SHAFT FRONT BEARING INNER RACE

| (a) Using SST and a press, install the input shaft front bearing inner race to the input shaft. SST: 09608-00071 |

|

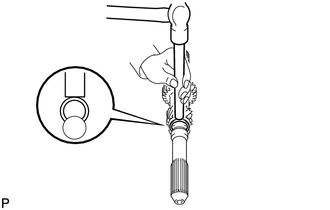

2. INSTALL INPUT SHAFT SNAP RING

| (a) Using a brass bar and hammer, tap a new input shaft snap ring to the input shaft. |

|

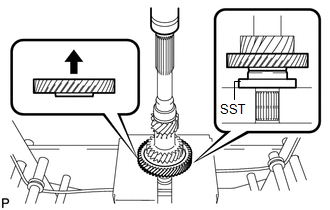

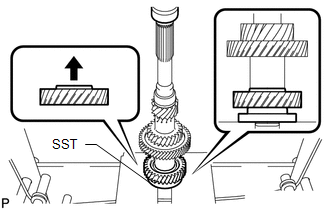

3. INSTALL 4TH DRIVE GEAR

| (a) Using SST and a press, install the 4th drive gear to the input shaft. SST: 09309-14040 |

|

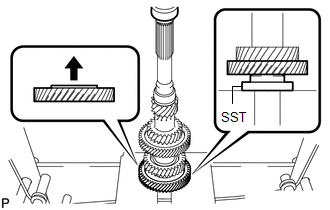

4. INSTALL 3RD DRIVE GEAR

| (a) Install the spacer to the input shaft. |

|

| (b) Using SST and a press, install the 3rd drive gear to the input shaft. SST: 09309-14040 |

|

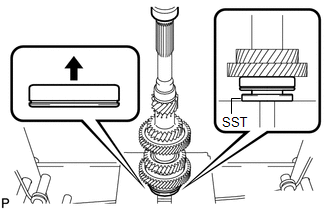

5. INSTALL 6TH DRIVE GEAR

| (a) Using SST and a press, install the 6th drive gear to the input shaft. SST: 09309-14040 |

|

6. INSTALL INPUT SHAFT REAR RADIAL BALL BEARING

| (a) Using SST and a press, install the input shaft rear radial ball bearing to the input shaft. SST: 09506-30012 |

|

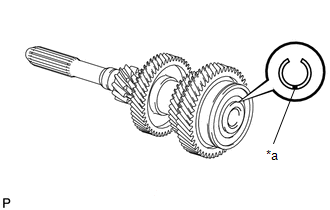

7. INSTALL INPUT SHAFT REAR BEARING SHAFT SNAP RING

| (a) Select a new input shaft rear bearing shaft snap ring, using the table below, that makes the thrust clearance of the input shaft bearing less than 0.1 mm (0.00394 in.). Input Shaft Rear Bearing Shaft Snap Ring Thickness:

|

|

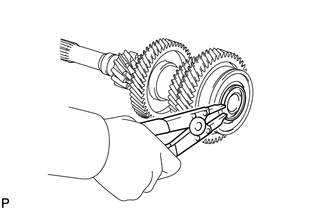

| (b) Using a snap ring expander, install the input shaft rear bearing shaft snap ring to the input shaft. |

|

Inspection

Inspection

INSPECTION PROCEDURE 1. INSPECT INPUT SHAFT (a) Check the input shaft for wear and damage.

(b) Using a dial indicator, measure the input shaft runout...

Intelligent Manual Transmission Switch

Intelligent Manual Transmission Switch

ComponentsCOMPONENTS ILLUSTRATION

*1 INTELLIGENT MANUAL TRANSMISSION SWITCH (COMBINATION SWITCH ASSEMBLY) - - InspectionINSPECTION PROCEDURE 1...

Other information:

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Precaution

PRECAUTION CHARGING SYSTEM PRECAUTION NOTICE: Check that the battery cables are connected to the correct terminals. Disconnect the battery cables when the auxiliary battery is given a quick charge. Do not perform tests with a high voltage insulation resistance tester...

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Installation

INSTALLATION PROCEDURE 1. INSTALL REAR CONSOLE BOX ASSEMBLY (a) Engage the claws and guides to install the rear console box assembly as shown in the illustration. Install in this Direction (1) Install in this Direction (2) (b) Install the 2 bolts and 2 screws...

Categories

- Manuals Home

- Toyota Yaris Owners Manual

- Toyota Yaris Service Manual

- Immobilizer System

- Brake System Control Module "A" System Voltage System Voltage Low (C137BA2)

- G16e-gts (engine Mechanical)

- New on site

- Most important about car

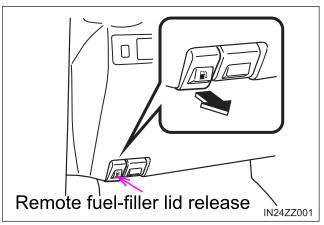

Refueling

Before refueling, close all the doors, windows, and the liftgate/trunk lid, and switch the ignition OFF.

To open the fuel-filler lid, pull the remote fuel-filler lid release.