Toyota Yaris: Sfi System / Mass or Volume Air Flow Sensor "A" Circuit Short to Battery (P010012,P010014)

DESCRIPTION

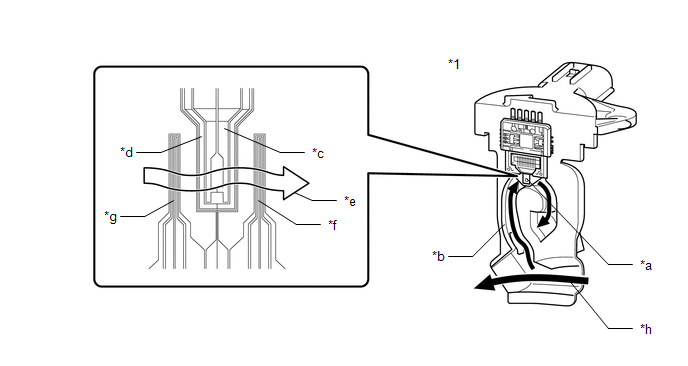

The mass air flow meter sub-assembly is a sensor that measures the intake air volume using the following built-in components:

- By-pass passage (allows some of the intake air to flow past a silicon chip sensor)

- Silicon chip sensor (uses a heater control bridge circuit and temperature sensor bridge circuit to detect the difference in the temperature of the intake air that passes the sensors positioned before and after the heater).

- Control circuit (converts the difference in temperature into a pulse signal and performs correction)

Intake air flows over the temperature sensor (before heater), the heater, and then the temperature sensor (after heater) on the silicon chip sensor in the by-pass passage. As the intake air is warmed up when it is exposed to the heater, the temperature of the intake air flowing over the temperature sensor (after heater) is higher than that over the temperature sensor (before heater). The difference in temperature of the intake air at each temperature sensor varies depending on the velocity of the intake air that flows over the silicon chip sensor. The temperature sensor bridge circuit detects the difference in temperature, and the control circuit converts it into a pulse signal and outputs it to the ECM. When the temperature detected by the temperature sensor (before heater) is higher than that detected by the temperature sensor (after heater), backflow of the intake air is detected.

The ECM calculates the intake air amount based on the pulse signal received from the mass air flow meter sub-assembly, and uses it to determine the fuel injection duration necessary for an optimal air-fuel ratio.

The heater control bridge circuit includes temperature sensors and power transistor, and maintains the heater temperature at a specific temperature.

HINT:

When DTCs are stored, the ECM enters fail-safe mode. During fail-safe mode, the ECM calculates the fuel injection duration based on the engine speed and throttle valve angle. Fail-safe mode continues until a pass condition is detected.

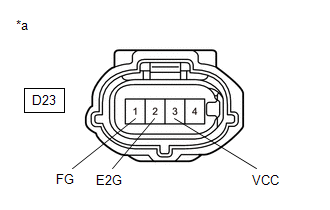

| *1 | Mass Air Flow Meter Sub-assembly | - | - |

| *a | Silicon Chip Sensor | *b | By-pass Duct |

| *c | Heater | *d | Heater Thermistor |

| *e | Intake Air | *f | Temperature Sensor (After Heater) |

| *g | Temperature Sensor (Before Heater) | *h | Air Flow |

| DTC No. | Detection Item | DTC Detection Condition | Trouble Area | MIL | Note |

|---|---|---|---|---|---|

| P010012 | Mass or Volume Air Flow Sensor "A" Circuit Short to Battery | The mass air flow meter sub-assembly output frequency is higher than 9.8 kHz for 3 seconds or more (1 trip detection logic). |

| Comes on | SAE: P0103 |

| P010014 | Mass or Volume Air Flow Sensor "A" Circuit Short to Ground or Open | The mass air flow meter sub-assembly output frequency is less than 0.1 kHz for 3 seconds or more (1 trip detection logic). |

| Comes on | SAE: P0102 |

MONITOR DESCRIPTION

If there is a defect or an open or short circuit in the mass air flow meter sub-assembly, the frequency level deviates from the normal operating range. The ECM interprets this deviation as a malfunction in the mass air flow meter sub-assembly circuit and stores a DTC.

Example:

When the sensor output frequency remains less than 0.1 kHz, or higher than 9.8 kHz for 3 seconds, the ECM stores a DTC.

MONITOR STRATEGY

| Frequency of Operation | Continuous |

CONFIRMATION DRIVING PATTERN

- Connect the GTS to the DLC3.

- Turn the ignition switch to ON.

- Turn the GTS on.

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

- Turn the ignition switch off and wait for at least 30 seconds.

- Turn the ignition switch to ON.

- Turn the GTS on.

- Wait 5 seconds or more [A].

- Enter the following menus: Powertrain / Engine / Trouble Codes [B].

-

Read the pending DTCs.

HINT:

- If a pending DTC is output, the system is malfunctioning.

- If a pending DTC is not output, perform the following procedure.

- Enter the following menus: Powertrain / Engine / Utility / All Readiness.

- Input the DTC: P010012 or P010014.

-

Check the DTC judgment result.

GTS Display

Description

NORMAL

- DTC judgment completed

- System normal

ABNORMAL

- DTC judgment completed

- System abnormal

INCOMPLETE

- DTC judgment not completed

- Perform driving pattern after confirming DTC enabling conditions

HINT:

- If the judgment result is NORMAL, the system is normal.

- If the judgment result is ABNORMAL, the system has a malfunction.

- If the judgment result is INCOMPLETE, perform steps [A] through [B] again.

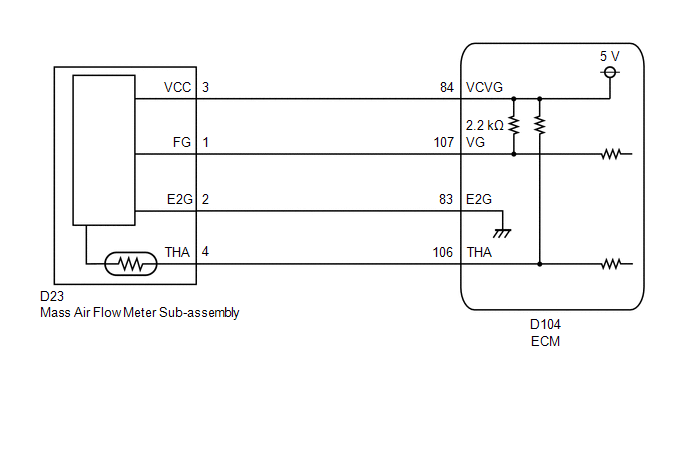

WIRING DIAGRAM

CAUTION / NOTICE / HINT

HINT:

Read Freeze Frame Data using the GTS. The ECM records vehicle and driving condition information as Freeze Frame Data the moment a DTC is stored. When troubleshooting, Freeze Frame Data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, if the air fuel ratio was lean or rich, and other data from the time the malfunction occurred.

PROCEDURE

| 1. | CHECK HARNESS AND CONNECTOR |

HINT:

Make sure that the connector is properly connected. If it is not, securely connect it and check for DTCs again.

(a) Disconnect the mass air flow meter sub-assembly connector.

(b) Turn the ignition switch to ON.

| (c) Measure the voltage according to the value(s) in the table below. Standard Voltage:

|

|

(d) Turn the ignition switch off and wait for at least 30 seconds.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| D23-3(VCC) - D23-1(FG) | Ignition switch off | 2.09 to 2.31 kΩ |

| D23-2(E2G) - Body ground | Always | Below 1 Ω |

HINT:

Perform "Inspection After Repair" after replacing the mass air flow meter sub-assembly.

Click here

| OK |

| REPLACE MASS AIR FLOW METER SUB-ASSEMBLY |

|

| 2. | CHECK HARNESS AND CONNECTOR (MASS AIR FLOW METER SUB-ASSEMBLY - ECM) |

(a) Disconnect the mass air flow meter sub-assembly connector.

(b) Disconnect the ECM connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| D23-3(VCC) - D104-84(VCVG) | Always | Below 1 Ω |

| D23-1(FG) - D104-107(VG) | Always | Below 1 Ω |

| D23-2(E2G) - D104-83(E2G) | Always | Below 1 Ω |

| D23-3(VCC) or D104-84(VCVG) - Body ground and other terminals | Always | 10 kΩ or higher |

| D23-1(FG) or D104-107(VG) - Body ground and other terminals | Always | 10 kΩ or higher |

| OK |

| REPLACE ECM |

| NG |

| REPAIR OR REPLACE HARNESS OR CONNECTOR |

Barometric Pressure - Turbocharger / Supercharger Boost Sensor "A" Signal Compare Failure (P00CF62)

Barometric Pressure - Turbocharger / Supercharger Boost Sensor "A" Signal Compare Failure (P00CF62)

DESCRIPTION At ignition switch to ON or during idling, the No. 2 turbo pressure sensor and the atmospheric pressure sensor built into the ECM are at atmospheric pressure and their outputs match...

Manifold Absolute Pressure / Barometric Pressure Sensor Circuit Short to Ground (P010511)

Manifold Absolute Pressure / Barometric Pressure Sensor Circuit Short to Ground (P010511)

DESCRIPTION

The No. 1 turbo pressure sensor detects the intake manifold pressure as a change in voltage. The ECM calculates the intake manifold pressure based on this voltage...

Other information:

Toyota Yaris XP210 (2020-2025) Reapir and Service Manual: Trouble in Passenger Airbag ON/OFF Indicator

DESCRIPTION This circuit detects the airbag cut off switch cylinder sub-assembly status. The passenger airbag ON/OFF indicator comes on to inform the driver of the instrument panel passenger without door airbag assembly status (activated or deactivated)...

Toyota Yaris XP210 (2020-2025) Reapir and Service Manual: Components

COMPONENTS ILLUSTRATION *A w/o LSD *B w/ LSD *1 FRONT DIFFERENTIAL RING GEAR *2 FRONT NO. 1 DIFFERENTIAL CASE SUB-ASSEMBLY *3 FRONT DIFFERENTIAL PINION SHAFT STRAIGHT PIN - - N*m (kgf*cm, ft.*lbf): Specified torque - - ILLUSTRATION *A w/o LSD - - *1 FRONT NO...

Categories

- Manuals Home

- Toyota Yaris Owners Manual

- Toyota Yaris Service Manual

- Immobilizer System

- Headlights

- How to use USB mode

- New on site

- Most important about car

Front Seat Belt Pretensioners

The front seat belt pretensioners are designed to deploy in moderate or severe frontal, near frontal collisions.

In addition, the pretensioners operate when a side collision or a rollover accident is detected. The pretensioners operate differently depending on what types of air bags are equipped. For more details about the seat belt pretensioner operation, refer to the SRS Air Bag Deployment Criteria.