Toyota Yaris: Power Steering Ecu / Installation

INSTALLATION

CAUTION / NOTICE / HINT

NOTICE:

After performing the update ECU security key procedure, make sure to perform the initialization procedure for when the cable has been disconnected and reconnected to the negative (-) auxiliary battery terminal.

PROCEDURE

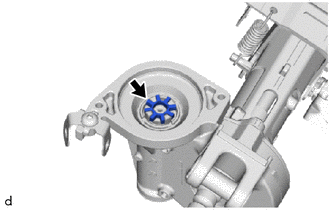

1. INSTALL ELECTRIC POWER STEERING MOTOR SHAFT DAMPER

| Grease |

(a) Apply grease to a new electric power steering motor shaft damper.

NOTICE:

First wipe off the existing grease from the serrated part, and then apply the dedicated grease supplied with a new power steering ECU assembly or electric power steering column sub-assembly.

| (b) Install the electric power steering motor shaft damper to the electric power steering column sub-assembly. |

|

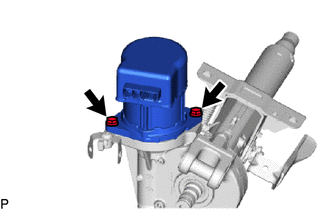

2. INSTALL POWER STEERING ECU ASSEMBLY

NOTICE:

- Do not drop the power steering ECU assembly, strike it with tools or subject it to impacts.

- If the power steering ECU assembly is subjected to an impact, replace it with a new one.

- Do not pull the wire harness of the electric power steering column sub-assembly.

- Do not allow any moisture to come into contact with the power steering ECU assembly.

- Do not loosen any bolts not mentioned in the procedure.

- Do not allow any foreign matter to contaminate the power steering ECU assembly.

| (a) Temporarily install the power steering ECU assembly to the electric power steering column sub-assembly with the 2 bolts. NOTICE: When temporarily installing the 2 bolts to the power steering ECU assembly, do not tighten them all the way down. |

|

| (b) Using a 10 mm hexagon socket wrench, install the steering wheel assembly set bolt to the steering main shaft. NOTICE: Do not apply excessive torque to the steering wheel assembly set bolt by using a tool such as an impact wrench. HINT: The steering wheel assembly set bolt is used for turning the steering main shaft during inspection of the steering main shaft rotating torque. Remove the steering wheel assembly set bolt after performing this inspection. |

|

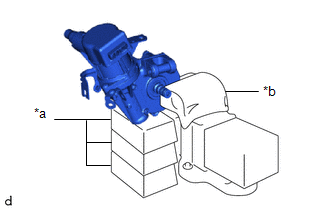

| (c) Secure the steering column assembly in a vise using aluminum plates, cloths and wooden blocks. NOTICE:

|

|

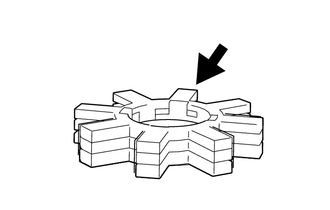

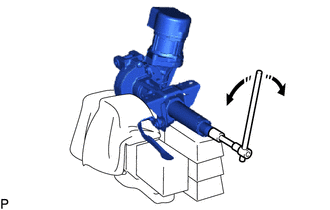

| Rotate |

(d) Rotate the steering main shaft 180 degrees counterclockwise and then 180 degrees clockwise at a speed of 60 rpm, and repeat 2 to 3 times to center the axis of the power steering ECU assembly. [*1]

(e) Tighten the 2 bolts. [*2]

Torque:

18.5 N·m {189 kgf·cm, 14 ft·lbf}

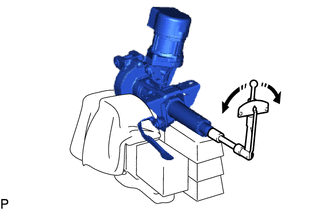

(f) Using a torque wrench, measure the turning torque of the steering main shaft.

Preload:

1.0 to 2.2 N*m (11 to 22 kgf*cm, 9 to 19 in.*lbf)

NOTICE:

Ensure that there is no abnormal resistance during rotation.

| Turn |

(g) If the turning torque is not as specified, loosen the 2 bolts and repeat steps [*1] and [*2] to recenter the axis of the power steering ECU assembly.

(h) Remove the steering wheel assembly set bolt.

(i) Connect the connector.

3. INSTALL STEERING LOCK ACTUATOR OR UPPER BRACKET ASSEMBLY

Click here

4. ALIGN FRONT WHEELS FACING STRAIGHT AHEAD

5. INSTALL STEERING COLUMN ASSEMBLY

Click here

6. INSTALL NO. 2 STEERING INTERMEDIATE SHAFT ASSEMBLY

Click here

7. CONNECT NO. 2 STEERING INTERMEDIATE SHAFT ASSEMBLY

Click here

8. INSTALL COLUMN HOLE COVER SILENCER SHEET

Click here

9. INSTALL NO. 1 AIR DUCT

Click here

10. INSTALL STOP LIGHT SWITCH ASSEMBLY

Click here

11. INSTALL LOWER INSTRUMENT PANEL FINISH PANEL ASSEMBLY

Click here

12. CONNECT HOOD LOCK CONTROL LEVER SUB-ASSEMBLY

Click here

13. INSTALL NO. 1 INSTRUMENT SIDE PANEL

Click here

14. INSTALL FRONT DOOR OPENING TRIM WEATHERSTRIP LH

Click here

15. INSTALL NO. 1 INSTRUMENT PANEL UNDER COVER SUB-ASSEMBLY

Click here

16. INSTALL COWL SIDE TRIM BOARD LH

Click here

17. INSTALL FRONT DOOR SCUFF PLATE LH

Click here

18. INSTALL CONSOLE BOX ASSEMBLY

Click here

19. INSTALL TURN SIGNAL SWITCH ASSEMBLY WITH SPIRAL CABLE SUB-ASSEMBLY

Click here

20. INSTALL UPPER STEERING COLUMN COVER

Click here

21. INSTALL LOWER STEERING COLUMN COVER

Click here

22. ALIGN FRONT WHEELS FACING STRAIGHT AHEAD

23. ADJUST SPIRAL CABLE WITH SENSOR SUB-ASSEMBLY

Click here

24. INSTALL STEERING WHEEL ASSEMBLY

Click here

25. INSTALL HORN BUTTON ASSEMBLY

Click here

26. CONNECT CABLE TO NEGATIVE AUXILIARY BATTERY TERMINAL

Click here

27. UPDATE ECU SECURITY KEY

Click here

28. PERFORM POWER STEERING ECU INITIAL SETTING

Click here

29. INSPECT HORN BUTTON ASSEMBLY

(a) Make sure that the horn sounds.

If the horn does not sound, inspect the horn system.

Click here

30. PERFORM CODE REGISTRATION

HINT:

When replacing the steering lock actuator or upper bracket assembly, perform code registration.

Click here

31. CHECK STEERING WHEEL CENTER POINT

Click here

32. PERFORM DIAGNOSTIC SYSTEM CHECK

Click here

33. INSPECT SRS WARNING LIGHT

Click here

34. INITIALIZATION AFTER RECONNECTING AUXILIARY BATTERY TERMINAL

HINT:

When disconnecting and reconnecting the auxiliary battery, there is an automatic learning function that completes learning when the respective system is used.

Click here

Removal

Removal

REMOVAL CAUTION / NOTICE / HINT The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during the power steering ECU assembly removal/installation are shown below...

Other information:

Toyota Yaris XP210 (2020-2026) Owner's Manual: Refueling

Before refueling, close all the doors, windows, and the liftgate/trunk lid, and switch the ignition OFF. To open the fuel-filler lid, pull the remote fuel-filler lid release. To remove the fuel-filler cap, turn it counterclockwise. Attach the removed cap to the inner side of the fuel-filler lid...

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Components

COMPONENTS ILLUSTRATION *1 FAN AND GENERATOR V BELT *2 ENGINE WIRE *3 NO. 2 AIR HOSE *4 ENGINE UNDER COVER RH *5 NO. 1 AIR TUBE *6 COMPRESSOR ASSEMBLY WITH PULLEY *7 NO. 1 ENGINE UNDER COVER ASSEMBLY - - N*m (kgf*cm, ft...

Categories

- Manuals Home

- Toyota Yaris Owners Manual

- Toyota Yaris Service Manual

- Removal

- How to use USB mode

- Diagnostic Trouble Code Chart

- New on site

- Most important about car

Front Seat Belt Pretensioners

The front seat belt pretensioners are designed to deploy in moderate or severe frontal, near frontal collisions.

In addition, the pretensioners operate when a side collision or a rollover accident is detected. The pretensioners operate differently depending on what types of air bags are equipped. For more details about the seat belt pretensioner operation, refer to the SRS Air Bag Deployment Criteria.