Toyota Yaris: Camshaft Position Sensor / Installation

INSTALLATION

PROCEDURE

1. INSTALL CAMSHAFT POSITION SENSOR (for Intake Side)

| (a) Clean the O-ring groove of the camshaft position sensor. NOTICE: Make sure the O-ring groove is free of foreign matter. |

|

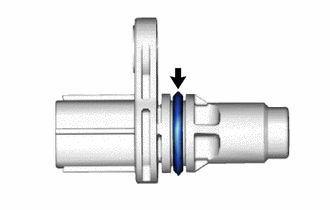

(b) Install a new O-ring to the camshaft position sensor.

NOTICE:

Set the O-ring on the tip of the camshaft position sensor and roll it into the O-ring groove with bare hands to install it.

(c) Check if the O-ring is twisted.

| (d) Install the camshaft position sensor to the cylinder head cover sub-assembly with a new bolt. Torque: 10 N·m {102 kgf·cm, 7 ft·lbf} NOTICE:

|

|

(e) Connect the camshaft position sensor connector.

2. INSTALL CAMSHAFT POSITION SENSOR (for Exhaust Side)

| (a) Clean the O-ring groove of the camshaft position sensor. NOTICE: Make sure the O-ring groove is free of foreign matter. |

|

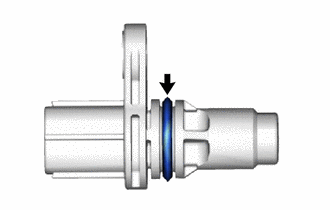

(b) Install a new O-ring to the camshaft position sensor.

NOTICE:

Set the O-ring on the tip of the camshaft position sensor and roll it into the O-ring groove with bare hands to install it.

(c) Check if the O-ring is twisted.

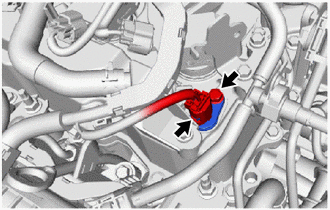

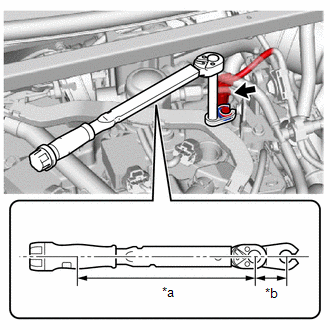

| (d) Using a 10 mm union nut wrench, install the camshaft position sensor to the cylinder head cover sub-assembly with a new bolt. Torque: Specified Tightening Torque : 10 N·m {102 kgf·cm, 7 ft·lbf} NOTICE:

HINT:

|

|

(e) Connect the camshaft position sensor connector.

3. INSTALL IGNITION COIL ASSEMBLY

(a) Install the bolt and ignition coil assembly.

Torque:

10 N·m {102 kgf·cm}

(b) Connect the ignition coil assembly connector.

4. INSTALL ENGINE WIRE

(a) Install the bolt and engine wire.

Torque:

10 N·m {102 kgf·cm}

5. INSPECT FOR ENGINE OIL LEAK

Click here

Removal

Removal

REMOVAL PROCEDURE 1. SEPARATE ENGINE WIRE (a) Remove the bolt and engine wire.

2. REMOVE IGNITION COIL ASSEMBLY (a) Disconnect the ignition coil assembly connector...

Crankshaft Position Sensor

Crankshaft Position Sensor

ComponentsCOMPONENTS ILLUSTRATION

*1 CRANKSHAFT POSITION SENSOR *2 O-RING

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping" : N*m (kgf*cm, ft...

Other information:

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Fuel Rail / System Pressure - Too High (P008800)

DESCRIPTION Refer to DTC P008700. Click here DTC No. Detection Item DTC Detection Condition Trouble Area MIL Note P008800 Fuel Rail / System Pressure - Too High Although the ECM is requesting the fuel pump assembly (for high pressure side) to open the spill control valve, fuel pressure increases 3 MPa (30...

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Reassembly

REASSEMBLY CAUTION / NOTICE / HINT CAUTION: Wear protective gloves. Sharp areas on the parts may injure your hands. PROCEDURE 1. INSTALL BENCH TYPE REAR SEAT CUSHION COVER NOTICE: When installing a bench type rear seat cushion cover, refer to Precaution in order to prevent wrinkles from forming...

Categories

- Manuals Home

- Toyota Yaris Owners Manual

- Toyota Yaris Service Manual

- To Set Speed

- Battery Monitor Module General Electrical Failure (P058A01)

- Maintenance

- New on site

- Most important about car

Front Seat Belt Pretensioners

The front seat belt pretensioners are designed to deploy in moderate or severe frontal, near frontal collisions.

In addition, the pretensioners operate when a side collision or a rollover accident is detected. The pretensioners operate differently depending on what types of air bags are equipped. For more details about the seat belt pretensioner operation, refer to the SRS Air Bag Deployment Criteria.