Toyota Yaris: G16e-gts (engine Control) / Crankshaft Position Sensor

Components

COMPONENTS

ILLUSTRATION

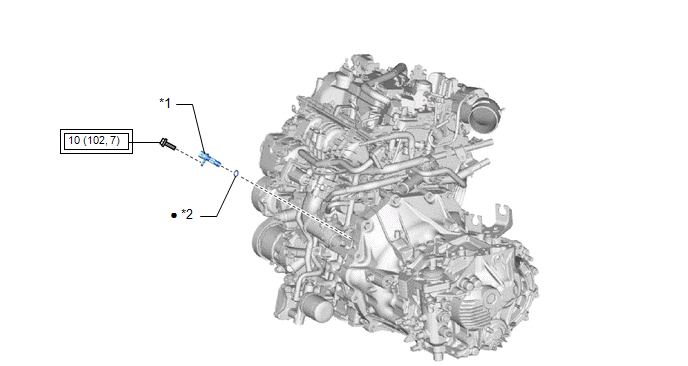

| *1 | CRANKSHAFT POSITION SENSOR | *2 | O-RING |

| Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping" : N*m (kgf*cm, ft.*lbf) | ● | Non-reusable part |

Removal

REMOVAL

PROCEDURE

1. REMOVE STARTER ASSEMBLY

Click here

2. REMOVE CRANKSHAFT POSITION SENSOR

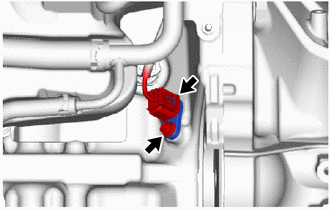

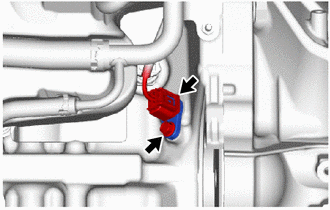

| (a) Disconnect the crankshaft position sensor connector. |

|

(b) Remove the bolt and crankshaft position sensor from the cylinder block sub-assembly.

NOTICE:

If the crankshaft position sensor has been struck or dropped, replace it.

| (c) Remove the O-ring from the crankshaft position sensor. NOTICE:

|

|

Installation

INSTALLATION

PROCEDURE

1. INSTALL CRANKSHAFT POSITION SENSOR

| (a) Clean the O-ring groove of the crankshaft position sensor. NOTICE: Make sure the O-ring groove is free of foreign matter. |

|

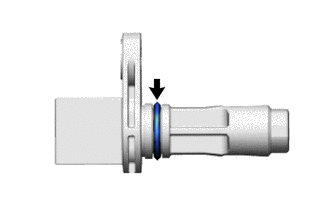

(b) Install a new O-ring to the crankshaft position sensor.

NOTICE:

Set the O-ring on the tip of the crankshaft position sensor and roll it into the O-ring groove with bare hands to install it.

(c) Check if the O-ring is twisted.

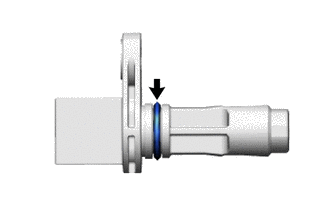

| (d) Install the crankshaft position sensor to the cylinder block sub-assembly with the bolt. Torque: 10 N·m {102 kgf·cm, 7 ft·lbf} NOTICE:

|

|

(e) Connect the crankshaft position sensor connector.

2. INSTALL STARTER ASSEMBLY

Click here

3. INSPECT FOR ENGINE OIL LEAK

Click here

Installation

Installation

INSTALLATION PROCEDURE 1. INSTALL CAMSHAFT POSITION SENSOR (for Intake Side) (a) Clean the O-ring groove of the camshaft position sensor. NOTICE: Make sure the O-ring groove is free of foreign matter...

Ecm

Ecm

..

Other information:

Toyota Yaris XP210 (2020-2026) Owner's Manual: Dashboard Illumination

When the position lights are turned on with the ignition switched ON, the brightness of the instrument panel illumination is dimmed. When the position lights are turned on, the position lights indicator light in the combination meter turns on. Refer to Headlights...

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Terminals Of Ecu

TERMINALS OF ECU CHECK AWD ECU ASSEMBLY (a) Measure the voltage and resistance of the connector. Terminal No. (Symbol) Terminal Description Condition Specified Condition O119-1 (GND) - Body ground Ground Always Below 1 Ω O119-2 (BSLC) - O119-1 (GND) AWD ECU assembly power supply Always 11 to 14 V O119-13 (T1H) - O119-1 (GND) Temperature sensor (+) input Ignition switch ON 0...

Categories

- Manuals Home

- Toyota Yaris Owners Manual

- Toyota Yaris Service Manual

- Maintenance

- Battery Monitor Module General Electrical Failure (P058A01)

- How to connect USB port/Auxiliary jack

- New on site

- Most important about car

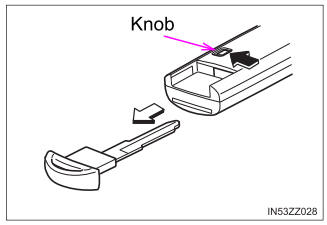

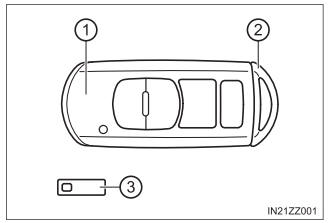

Keys

To use the auxiliary key, press the knob and pull out the auxiliary key from the smart key.