Toyota Yaris: Camshaft Position Sensor / Removal

REMOVAL

PROCEDURE

1. SEPARATE ENGINE WIRE

| (a) Remove the bolt and engine wire. |

|

2. REMOVE IGNITION COIL ASSEMBLY

| (a) Disconnect the ignition coil assembly connector. |

|

(b) Remove the bolt and ignition coil assembly.

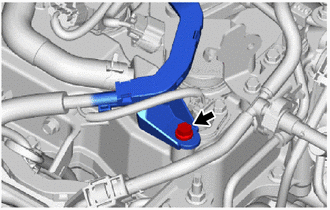

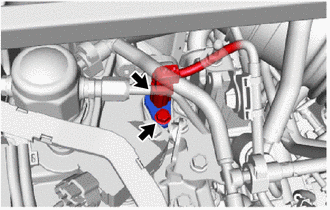

3. REMOVE CAMSHAFT POSITION SENSOR (for Intake Side)

| (a) Disconnect the camshaft position sensor connector. |

|

(b) Remove the bolt and camshaft position sensor from the cylinder head cover sub-assembly.

NOTICE:

If the camshaft position sensor has been struck or dropped, replace it.

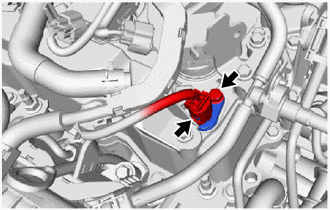

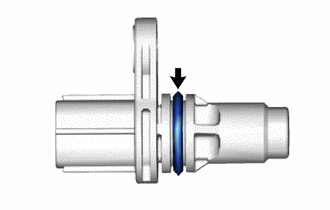

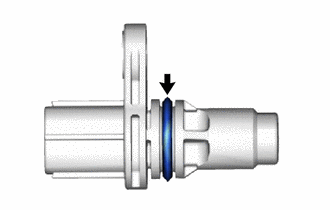

| (c) Remove the O-ring from the camshaft position sensor. NOTICE:

|

|

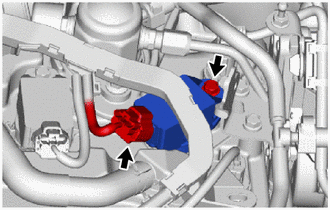

4. REMOVE CAMSHAFT POSITION SENSOR (for Exhaust Side)

| (a) Disconnect the camshaft position sensor connector. |

|

(b) Remove the bolt and camshaft position sensor from the cylinder head cover sub-assembly.

NOTICE:

If the camshaft position sensor has been struck or dropped, replace it.

| (c) Remove the O-ring from the camshaft position sensor. NOTICE:

|

|

Components

Components

COMPONENTS ILLUSTRATION

*A for Intake Side *B for Exhaust Side *1 CAMSHAFT POSITION SENSOR *2 IGNITION COIL ASSEMBLY *3 ENGINE WIRE *4 O-RING

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping" : N*m (kgf*cm, ft...

Installation

Installation

INSTALLATION PROCEDURE 1. INSTALL CAMSHAFT POSITION SENSOR (for Intake Side) (a) Clean the O-ring groove of the camshaft position sensor. NOTICE: Make sure the O-ring groove is free of foreign matter...

Other information:

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Steering Angle Sensor Supply Voltage Circuit Circuit Short to Ground or Open (C14FE14)

DESCRIPTION This DTC is stored when the skid control ECU (brake actuator assembly) receives a power supply malfunction signal from the steering sensor. DTC No. Detection Item DTC Detection Condition Trouble Area DTC Output from C14FE14 Steering Angle Sensor Supply Voltage Circuit Circuit Short to Ground or Open When the +BS terminal voltage is from 9...

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Lost Communication with ECM/PCM "A" Missing Message (U010087,U010187,U012687,U012987,U015587)

DESCRIPTION The following DTCs are stored when there is a communication malfunction between the millimeter wave radar sensor and each sensor or ECU. DTC No. Detection Item DTC Detection Condition Trouble Area U010087 Lost Communication with ECM/PCM "A" Missing Message When the ignition switch is ON for 3 seconds or more, an ECM communication malfunction continues for approximately 3 seconds or more...

Categories

- Manuals Home

- Toyota Yaris Owners Manual

- Toyota Yaris Service Manual

- Maintenance

- Immobilizer System

- Diagnostic Trouble Code Chart

- New on site

- Most important about car

Turning the Engine Off

Stop the vehicle completely. Manual transaxle: Shift into neutral and set the parking brake.Automatic transaxle: Shift the selector lever to the P position and set the parking brake.

Press the push button start to turn off the engine. The ignition position is off.