Toyota Yaris: Canister / Inspection

INSPECTION

PROCEDURE

1. CHECK CANISTER (FUEL SUCTION WITH PUMP AND GAUGE TUBE ASSEMBLY)

(a) Visually check the canister (fuel suction with pump and gauge tube assembly).

(1) Visually check the canister (fuel suction with pump and gauge tube assembly) for cracks or damage.

If cracks or damage are found, replace the canister (fuel suction with pump and gauge tube assembly).

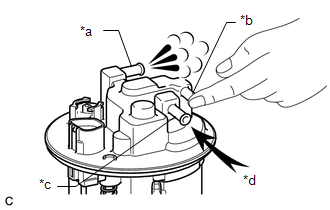

(b) Inspect the airflow of the canister (fuel suction with pump and gauge tube assembly).

| (1) Close the port (B) and check that air flows from the port (A) when air is blown into the port (C). OK: Air flows from the port (A). |

|

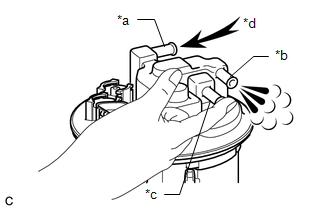

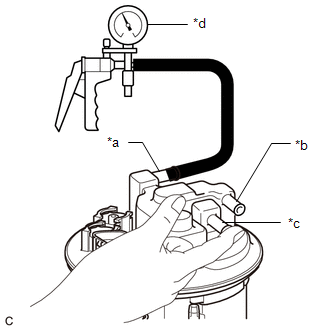

(c) Inspect the check valve.

| (1) Close the port (C) and check that air flows from the port (B) when air is blown into the port (A). OK: Air flows from the port (B). |

|

| (2) Using a vacuum pump, apply vacuum to the port (A) with the port (C) closed and check that air flows into the port (B). OK: The vacuum is maintained at first. By gradually increasing the vacuum, air flows and the vacuum decreases after the vacuum reaches a certain level. |

|

Removal

Removal

REMOVAL CAUTION / NOTICE / HINT The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during canister (fuel suction plate sub-assembly) removal/installation are shown below...

Installation

Installation

INSTALLATION PROCEDURE 1. INSTALL FUEL MAIN VALVE ASSEMBLY Click here

2. INSTALL FUEL PUMP Click here

3. INSTALL FUEL SENDER GAUGE ASSEMBLY Click here

4...

Other information:

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Removal

REMOVAL CAUTION / NOTICE / HINT The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed, installed, or replaced during the front stabilizer bar removal/installation are shown below...

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Failure to Restart from IG-ON Engine Stall

DESCRIPTION This is the troubleshooting procedure for situations where the engine does not restart when attempting to restart it after either a failed engine start occurred under stop and start system control, or a mis-operation during vehicle takeoff resulted in an engine stall...

Categories

- Manuals Home

- Toyota Yaris Owners Manual

- Toyota Yaris Service Manual

- How to use USB mode

- Diagnostic Trouble Code Chart

- Brake System Control Module "A" System Voltage System Voltage Low (C137BA2)

- New on site

- Most important about car

Fuel Gauge

The fuel gauge shows approximately how much fuel is remaining in the tank when the ignition is switched ON. We recommend keeping the tank over 1/4 full.