Toyota Yaris: Turbocharger / Inspection

INSPECTION

PROCEDURE

1. INSPECT TURBOCHARGER SUB-ASSEMBLY

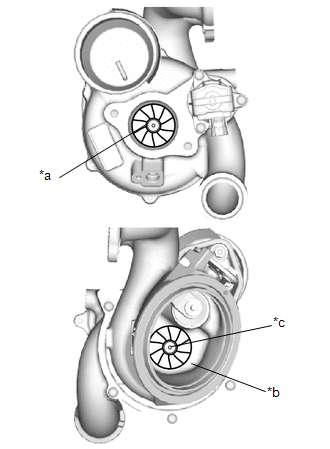

| (a) Check if the compressor side impeller and exhaust side turbine are damaged or defective. HINT: Wear on the center of the exhaust side turbine is not a malfunction. |

|

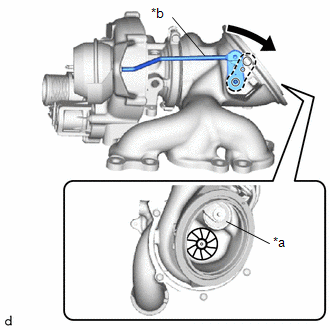

| (b) Move the rod by hand and check that the waste gate valve is not stuck. |

|

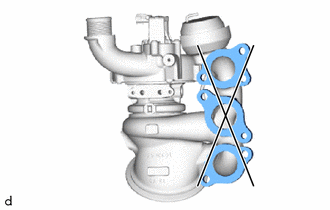

| (c) Using a straightedge and feeler gauge, check the turbocharger sub-assembly installation surface for warpage. Standard Warpage: 0.15 mm (0.00591 in.) or less If the result is not as specified, replace the turbocharger sub-assembly. |

|

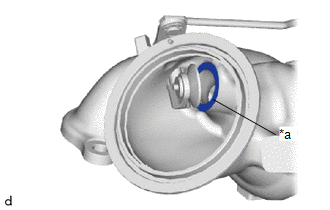

| (d) Close the waste gate valve and using a feeler gauge, measure the clearance between the waste gate valve and the contact surface of the valve port of the turbine with valve housing sub-assembly waste gate. Standard Clearance: 0.15 mm (0.00591 in.) or less If the result is not as specified, replace the turbocharger sub-assembly. |

|

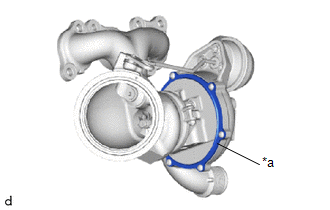

| (e) Check the areas shown in the illustration for oil leakage. OK: There are no oil leaks from the compressor with bearing housing sub-assembly. NOTICE: Oil on the inlet side of the compressor is from oil in the blow-by gas and is not a malfunction. If the result is not as specified, replace the turbocharger sub-assembly. |

|

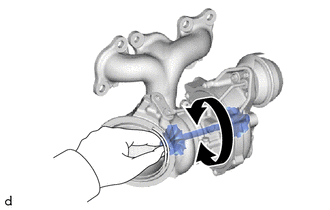

| (f) Rotate the compressor wheel by hand as shown in the illustration, and check that the compressor wheel rotates smoothly. OK: Compressor wheel rotates smoothly. HINT: If the compressor wheel does not rotate smoothly, replace the turbocharger sub-assembly. |

|

(g) Check that the turbine shaft rotates smoothly.

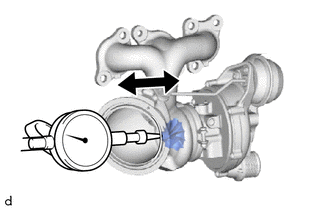

| (1) Set a dial indicator to the outlet side of the turbine shaft. |

|

(2) Move the turbine shaft in the axial direction and check for play.

Standard Axial Play:

0.15 mm (0.00591 in.) or less

If the result is not as specified, replace the turbocharger sub-assembly.

2. INSPECT WASTE GATE VALVE ACTUATOR

(a) Check the waste gate valve actuator hose for cracks and damage.

(b) Check the waste gate valve actuator with bracket assembly air hole.

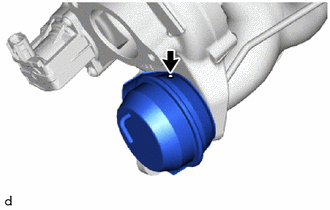

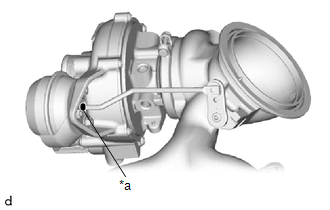

| (1) Check that the waste gate valve actuator air hole shown in the illustration is not clogged. |

|

(c) Check the waste gate valve actuator with bracket assembly travel.

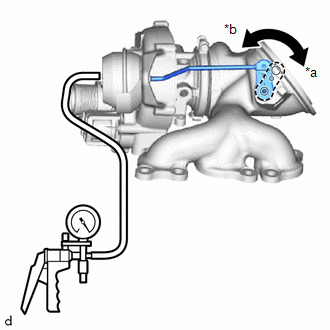

(1) Connect a vacuum pump to the waste gate valve actuator.

| (2) Using a vacuum pump, apply a vacuum of 30 +/- 4.0 kPa (225 +/- 30 mmHg, 8.8 +/- 1.2 in. Hg) to the diaphragm chamber to operate the waste gate valve actuator. OK: The waste gate valve closes when vacuum is applied. NOTICE: Do not apply a vacuum of 65 kPa (488 mmHg, 19.2 in. Hg) or more to the waste gate valve actuator as doing so may damage the diaphragm. HINT: If the waste gate valve actuator does not operate, replace the turbocharger sub-assembly. |

|

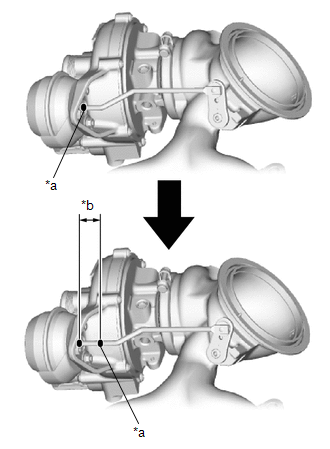

| (3) Place a paint mark on the waste gate valve actuator rod from the waste gate valve actuator bracket as shown in the illustration. |

|

(4) Using a vernier caliper, measure the distance from the waste gate valve actuator bracket to the paint mark at a vacuum of 0 kPa (0 mmHg, 0 in. Hg).

| *a | Paint Mark |

| *b | Travel of Waste Gate Valve Actuator |

| Vacuum at 0 kPa (0 mmHg, 0 in. Hg) |

Standard:

15 mm (0.591 in.) or more

If the result is not as specified, replace the turbocharger sub-assembly.

NOTICE:

If the result is not as specified when replacing the turbocharger sub-assembly, and check the travel of the waste gate valve actuator again.

(5) Disconnect the vacuum pump from the waste gate valve actuator.

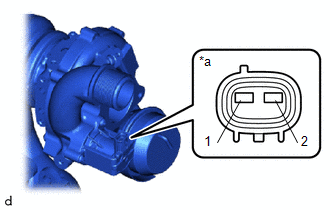

3. INSPECT INTAKE AIR CONTROL VALVE (AIR BY-PASS VALVE ASSEMBLY)

(a) Inspect the resistance.

| (1) Measure the resistance according to the value(s) in the table below. Standard Resistance:

If the result is not as specified, replace the turbocharger sub-assembly. |

|

Removal

Removal

REMOVAL CAUTION / NOTICE / HINT The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during exhaust manifold removal/installation are shown below...

Installation

Installation

INSTALLATION PROCEDURE 1. INSTALL STUD BOLT (a) Using an E8 "TORX" socket wrench, install the stud bolt to the turbocharger sub-assembly. Torque: 10 N·m {102 kgf·cm, 7 ft·lbf} 2...

Other information:

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Turbocharger Noise

DESCRIPTION HINT: Turbocharger noise is classified into two types. These are whistling sound and chattering sound. During troubleshooting, first determine the type of noise. Type of Abnormal Noise Outline of Abnormal Noise Major Trouble Area Whistling sound (airflow sound) The whistling sound volume and pitch are proportional to the turbocharger or engine speed...

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Precaution

PRECAUTION CAUTION REGARDING INTERFERENCE WITH ELECTRONIC DEVICES CAUTION: As weak radio waves are emitted from the electrical key transmitter sub-assembly, if a pacemaker is being used, be sure to read the pacemaker instruction manual and the following...

Categories

- Manuals Home

- Toyota Yaris Owners Manual

- Toyota Yaris Service Manual

- Headlights

- How to connect USB port/Auxiliary jack

- Opening and Closing the Liftgate/Trunk Lid

- New on site

- Most important about car

Fuel-Filler Lid and Cap

WARNING

When removing the fuel-filler cap, loosen the cap slightly and wait for any hissing to stop, then remove it

Fuel spray is dangerous. Fuel can burn skin and eyes and cause illness if ingested. Fuel spray is released when there is pressure in the fuel tank and the fuel-filler cap is removed too quickly.