Toyota Yaris: Sfi System / Engine Oil Pressure Sensor/Switch "A" Circuit Short to Battery (P052012,P052014)

DESCRIPTION

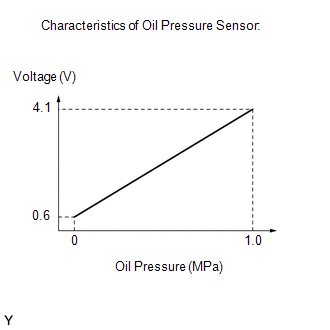

The oil pressure sensor (engine oil pressure and temperature sensor) utilizes a semiconductor type pressure sensor that changes resistance in accordance with changes in pressure. An internal electrical signal that varies with the change in resistance is amplified and sent to the ECM as the engine oil pressure signal.

| DTC No. | Detection Item | DTC Detection Condition | Trouble Area | MIL | Note |

|---|---|---|---|---|---|

| P052012 | Engine Oil Pressure Sensor/Switch "A" Circuit Short to Battery | The oil pressure sensor (engine oil pressure and temperature sensor) output voltage is higher than 4.495 V for 5 seconds or more (1 trip detection logic). |

| Comes on | SAE: P0523 |

| P052014 | Engine Oil Pressure Sensor/Switch "A" Circuit Short to Ground or Open | The oil pressure sensor (engine oil pressure and temperature sensor) output voltage is below 0.159 V for 5 seconds or more (1 trip detection logic). |

| Comes on | SAE: P0522 |

| DTC No. | Data List |

|---|---|

| P052012 | Engine Oil Pressure |

| P052014 |

MONITOR DESCRIPTION

The ECM calculates the engine oil pressure based on the output voltage of the oil pressure sensor (engine oil pressure and temperature sensor). If the signal output from the oil pressure sensor is outside of the specified range, the MIL is illuminated and a DTC is stored.

MONITOR STRATEGY

| Frequency of Operation | Continuous |

CONFIRMATION DRIVING PATTERN

- Connect the GTS to the DLC3.

- Turn the ignition switch to ON.

- Turn the GTS on.

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

- Turn the ignition switch off and wait for at least 30 seconds.

- Turn the ignition switch to ON.

- Turn the GTS on.

- Wait 10 seconds or more.

- Enter the following menus: Powertrain / Engine / Trouble Codes.

-

Read the pending DTCs.

HINT:

- If a pending DTC is output, the system is malfunctioning.

- If a pending DTC is not output, perform the following procedure.

- Enter the following menus: Powertrain / Engine / Utility / All Readiness.

- Input the DTC: P052012 or P052014.

-

Check the DTC judgment result.

GTS Display

Description

NORMAL

- DTC judgment completed

- System normal

ABNORMAL

- DTC judgment completed

- System abnormal

INCOMPLETE

- DTC judgment not completed

- Perform driving pattern after confirming DTC enabling conditions

HINT:

- If the judgment result is NORMAL, the system is normal.

- If the judgment result is ABNORMAL, the system is malfunctioning.

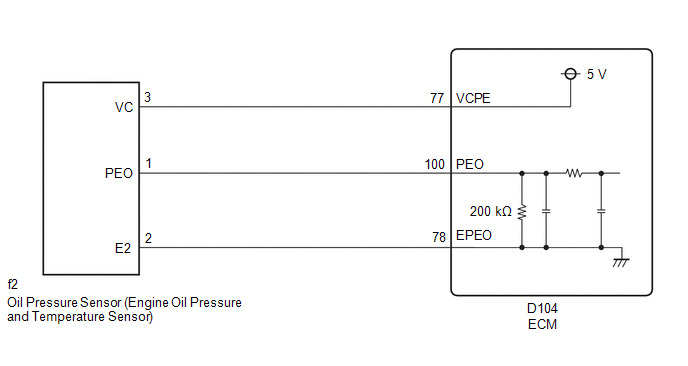

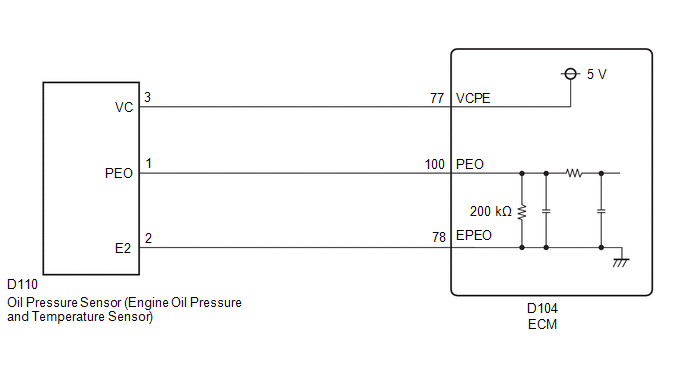

WIRING DIAGRAM

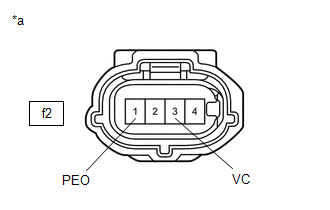

Production date from 2021/04 to 2021/07 Production date from 2021/07

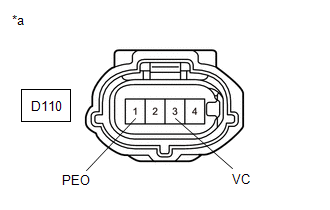

Production date from 2021/07

CAUTION / NOTICE / HINT

HINT:

Read Freeze Frame Data using the GTS. The ECM records vehicle and driving condition information as Freeze Frame Data the moment a DTC is stored. When troubleshooting, Freeze Frame Data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, if the air fuel ratio was lean or rich, and other data from the time the malfunction occurred.

PROCEDURE

| 1. | CHECK VEHICLE SPECIFICATION |

(a) Check the vehicle specification

| Result | Proceed to |

|---|---|

| Production date from 2021/04 to 2021/07 | A |

| Production date from 2021/07 | B |

| B |

| GO TO STEP 4 |

|

| 2. | CHECK HARNESS AND CONNECTOR |

HINT:

Make sure that the connector is properly connected. If it is not, securely connect it and check for DTCs again.

(a) Disconnect the oil pressure sensor (engine oil pressure and temperature sensor) connector.

(b) Turn the ignition switch to ON.

| (c) Measure the voltage according to the value(s) in the table below. Standard Voltage:

|

|

(d) Turn the ignition switch off and wait for at least 30 seconds.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| f2-1(PEO) - f2-2(E2) | Ignition switch off | 190 to 210 kΩ |

| f2-2(E2) - Body ground | Always | Below 1 Ω |

| OK |

| REPLACE OIL PRESSURE SENSOR (ENGINE OIL PRESSURE AND TEMPERATURE SENSOR) |

|

| 3. | CHECK HARNESS AND CONNECTOR (OIL PRESSURE SENSOR (ENGINE OIL PRESSURE AND TEMPERATURE SENSOR) - ECM) |

(a) Disconnect the oil pressure sensor (engine oil pressure and temperature sensor) connector.

(b) Disconnect the ECM connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| f2-2(E2) - D104-78(EPEO) | Always | Below 1 Ω |

| f2-1(PEO) - D104-100(PEO) | Always | Below 1 Ω |

| f2-3(VC) - D104-77(VCPE) | Always | Below 1 Ω |

| f2-2(E2) or D104-78(EPEO) - Body ground and other terminals | Always | 10 kΩ or higher |

| f2-1(PEO) or D104-100(PEO) - Body ground and other terminals | Always | 10 kΩ or higher |

| f2-3(VC) or D104-77(VCPE) - Body ground and other terminals | Always | 10 kΩ or higher |

| OK |

| REPLACE ECM |

| NG |

| REPAIR OR REPLACE HARNESS OR CONNECTOR |

| 4. | CHECK HARNESS AND CONNECTOR |

HINT:

Make sure that the connector is properly connected. If it is not, securely connect it and check for DTCs again.

(a) Disconnect the oil pressure sensor (engine oil pressure and temperature sensor) connector.

(b) Turn the ignition switch to ON.

| (c) Measure the voltage according to the value(s) in the table below. Standard Voltage:

|

|

(d) Turn the ignition switch off and wait for at least 30 seconds.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| D110-1(PEO) - D110-2(E2) | Ignition switch off | 190 to 210 kΩ |

| D110-2(E2) - Body ground | Always | Below 1 Ω |

| OK |

| REPLACE OIL PRESSURE SENSOR (ENGINE OIL PRESSURE AND TEMPERATURE SENSOR) |

|

| 5. | CHECK HARNESS AND CONNECTOR (OIL PRESSURE SENSOR (ENGINE OIL PRESSURE AND TEMPERATURE SENSOR) - ECM) |

(a) Disconnect the oil pressure sensor (engine oil pressure and temperature sensor) connector.

(b) Disconnect the ECM connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| D110-2(E2) - D104-78(EPEO) | Always | Below 1 Ω |

| D110-1(PEO) - D104-100(PEO) | Always | Below 1 Ω |

| D110-3(VC) - D104-77(VCPE) | Always | Below 1 Ω |

| D110-2(E2) or D104-78(EPEO) - Body ground and other terminals | Always | 10 kΩ or higher |

| D110-1(PEO) or D104-100(PEO) - Body ground and other terminals | Always | 10 kΩ or higher |

| D110-3(VC) or D104-77(VCPE) - Body ground and other terminals | Always | 10 kΩ or higher |

| OK |

| REPLACE ECM |

| NG |

| REPAIR OR REPLACE HARNESS OR CONNECTOR |

Brake Switch "A"/"B" Signal Cross Coupled (P05042B)

Brake Switch "A"/"B" Signal Cross Coupled (P05042B)

DESCRIPTION The stop light switch assembly is a duplex system that transmits two signals: STP and ST1-. These two signals are used by the ECM to monitor whether or not the brake system is working properly...

Engine Oil Pressure Sensor/Switch "A" Signal Stuck High (P052024,P05202A)

Engine Oil Pressure Sensor/Switch "A" Signal Stuck High (P052024,P05202A)

DESCRIPTION Refer to DTC P052012. Click here

DTC No. Detection Item DTC Detection Condition Trouble Area MIL Note P052024 Engine Oil Pressure Sensor/Switch "A" Signal Stuck High The oil pressure sensor output voltage is higher than the threshold value (1 trip detection logic)...

Other information:

Toyota Yaris XP210 (2020-2026) Owner's Manual: Towing Description

We recommend that towing be done only by your Toyota dealer or a commercial tow-truck service. Proper lifting and towing are necessary to prevent damage to the vehicle. Government and local laws must be followed. A towed vehicle usually should have its drive wheels (front wheels) off the ground...

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Data List / Active Test

DATA LIST / ACTIVE TEST DATA LIST (BRAKE) NOTICE: In the table below, the values listed under "Normal Condition" are reference values. Do not depend solely on these reference values when deciding whether a part is faulty or not. HINT: Using the GTS to read the Data List allows the values or states of switches, sensors, actuators and other items to be read without removing any parts...

Categories

- Manuals Home

- Toyota Yaris Owners Manual

- Toyota Yaris Service Manual

- Headlights

- Fuse Panel Description

- Brake System Control Module "A" System Voltage System Voltage Low (C137BA2)

- New on site

- Most important about car

Turning the Engine Off

Stop the vehicle completely. Manual transaxle: Shift into neutral and set the parking brake.Automatic transaxle: Shift the selector lever to the P position and set the parking brake.

Press the push button start to turn off the engine. The ignition position is off.