Toyota Yaris: Cylinder Head / Disassembly

DISASSEMBLY

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during cylinder head removal/installation are shown below.

Necessary Procedure After Parts Removed/Installed/Replaced| Replaced Part or Performed Procedure | Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed | Link |

|---|---|---|---|

| Cylinder head sub-assembly | Inspection after repair |

|

|

PROCEDURE

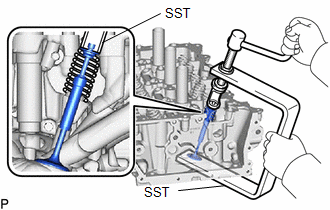

1. REMOVE INTAKE VALVE

| (a) Using SST, compress each compression spring and remove the 6 valve spring retainer locks. SST: 09202-70020 09202-01010 09202-01020 SST: 09202-00021 HINT: Arrange the removed parts in such a way that they can be reinstalled to their original locations. |

|

(b) Remove the 6 valve spring retainers, 6 compression springs and 6 intake valves from the cylinder head sub-assembly.

HINT:

Arrange the removed parts in such a way that they can be reinstalled to their original locations.

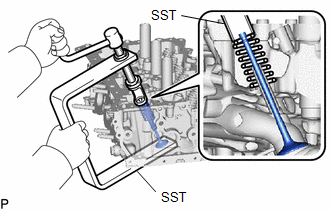

2. REMOVE EXHAUST VALVE

CAUTION:

- The exhaust valve is filled with sodium. Sodium is a strong alkali which may produce a dangerous chemical reaction. Therefore, be very careful when handling and disposing of it.

- Do not disassemble the exhaust valve for the following reasons: 1) If sodium enters your eyes, vision loss may occur. 2) If sodium contacts your skin, burns may occur. 3) If sodium is exposed to a flame and starts a fire due to the chemical reaction that takes place, burns may occur.

- If the exhaust valve is damaged, remove the valve and perform the proper procedures to dispose of the sodium (disposal preparation and actual disposal).

- When removing a damaged exhaust valve, always wear rubber gloves and safety glasses.

- Do not cut the exhaust valve to take out the sodium.

HINT:

- The sodium inside the exhaust valve is safe as long as the sodium is not exposed to air.

- Exhaust valves filled with sodium can be identified by confirming the "NA" identification mark.

| (a) Using SST, compress each compression spring and remove the 6 valve spring retainer locks. SST: 09202-70020 09202-01010 09202-01020 SST: 09202-00021 HINT: Arrange the removed parts in such a way that they can be reinstalled to their original locations. |

|

(b) Remove the 6 valve spring retainers, 6 compression springs and 6 exhaust valves from the cylinder head sub-assembly.

HINT:

Arrange the removed parts in such a way that they can be reinstalled to their original locations.

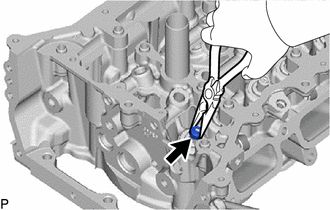

3. REMOVE VALVE STEM OIL SEAL

| (a) Using needle-nose pliers, remove the 12 valve stem oil seals. |

|

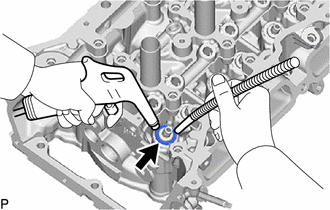

4. REMOVE VALVE SPRING SEAT

| (a) Using compressed air and a Magnet Hand, remove the 12 valve spring seats from the cylinder head sub-assembly by blowing air onto them. |

|

5. REMOVE NO. 1 STRAIGHT SCREW PLUG

NOTICE:

If coolant leaks from a No. 1 straight screw plug or a plug is corroded, replace it.

(a) Using a 6 mm straight hexagon wrench, remove the 2 No. 1 straight screw plugs from the cylinder head sub-assembly.

6. REMOVE NO. 2 STRAIGHT SCREW PLUG

NOTICE:

If coolant leaks from a No. 2 straight screw plug or a plug is corroded, replace it.

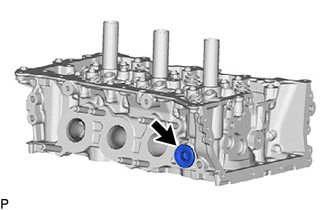

| (a) Using a 10 mm straight hexagon wrench, remove the No. 2 straight screw plug from the cylinder head sub-assembly. |

|

7. REMOVE STUD BOLT

NOTICE:

If a stud bolt is deformed or its threads are damaged, replace it.

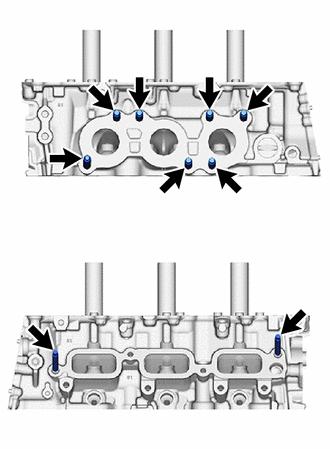

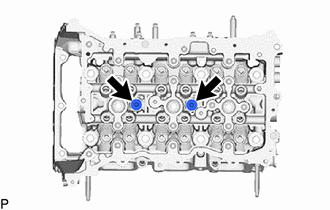

| (a) Using an E8 "TORX" socket wrench, remove the 9 stud bolts. |

|

8. REMOVE STRAIGHT PIN

NOTICE:

If a straight pin is deformed or its threads are damaged, replace it.

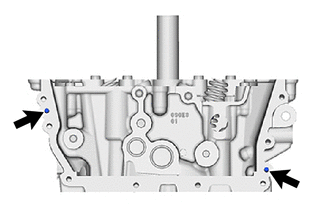

| (a) Remove the 2 straight pin. |

|

9. DISPOSE OF EXHAUST VALVE

CAUTION:

- The exhaust valve is filled with sodium. Sodium is a strong alkali which may produce a dangerous chemical reaction. Therefore, be very careful when handling and disposing of it.

- Do not disassemble the exhaust valve for the following reasons: 1) If sodium enters your eyes, vision loss may occur. 2) If sodium contacts your skin, burns may occur. 3) If sodium is exposed to a flame and starts a fire due to the chemical reaction that takes place, burns may occur.

- If the exhaust valve is damaged, remove the valve and perform the proper procedures to dispose of the sodium (disposal preparation and actual disposal).

- When removing a damaged exhaust valve, always wear rubber gloves and safety glasses.

- Do not cut the exhaust valve to take out the sodium.

NOTICE:

If it is clearly stated that the industrial waste disposal method is dissolution, carry out the process below.

HINT:

- The sodium inside the exhaust valve is safe as long as the sodium is not exposed to air.

- Exhaust valves filled with sodium can be identified by confirming the "NA" identification mark.

(a) Waste disposal preparation

CAUTION:

Always carry out the following when performing the disposal procedure.

(1) Have a fire extinguisher close by.

(2) Wear safety glasses.

(3) Wear rubber gloves.

(b) Waste disposal

(1) Put on rubber gloves and remove the damaged exhaust valve from the cylinder head.

(2) Add 10 L of water or more to a large receptacle (a bucket, oil can, etc.) in a well-ventilated area.

(3) Hold the damaged exhaust valve upright with pliers or large pair of tweezers and submerge it into the water.

CAUTION:

- Fully submerge the damaged exhaust valve in water.

- Do not allow any sparks or other flames near the receptacle as hydrogen gas is generated by the chemical reaction.

- Stay 2 or 3 m or more away from the receptacle as a strong chemical reaction occurs.

Components

Components

COMPONENTS ILLUSTRATION

*1 INTAKE VALVE GUIDE BUSH *2 EXHAUST VALVE GUIDE BUSH *3 SPARK PLUG TUBE *4 RING PIN *5 STUD BOLT *6 VALVE SPRING RETAINER LOCK *7 NO...

Inspection

Inspection

INSPECTION PROCEDURE 1. INSPECT CYLINDER HEAD SUB-ASSEMBLY (a) Using a precision straightedge and feeler gauge, measure the warpage of the contact surfaces where the cylinder head sub-assembly contacts the cylinder block sub-assembly, intake manifold and exhaust manifold...

Other information:

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Back Door Entry Lock Function does not Operate

DESCRIPTION If the entry lock function does not operate for the back door only, but the entry unlock function operates, the request code is being transmitted properly from the back door. In this case, there may be a problem related to the lock switch (connection between the back door opener switch assembly and certification ECU (smart key ECU assembly))...

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Disassembly

DISASSEMBLY PROCEDURE 1. REMOVE SELECTING BELL CRANK ASSEMBLY (a) Remove the 2 bolts and selecting bell crank assembly from the manual transmission case. 2. REMOVE CONTROL SHIFT LEVER BUSHING (a) Remove the control shift lever bushing from the selecting bell crank assembly...

Categories

- Manuals Home

- Toyota Yaris Owners Manual

- Toyota Yaris Service Manual

- Diagnostic Trouble Code Chart

- Opening and Closing the Liftgate/Trunk Lid

- Headlights

- New on site

- Most important about car

Fuel-Filler Lid and Cap

WARNING

When removing the fuel-filler cap, loosen the cap slightly and wait for any hissing to stop, then remove it

Fuel spray is dangerous. Fuel can burn skin and eyes and cause illness if ingested. Fuel spray is released when there is pressure in the fuel tank and the fuel-filler cap is removed too quickly.