Toyota Yaris: Vehicle Stability Control System / Right Rear Wheel Speed Sensor Circuit Intermittent (C05121F)

DESCRIPTION

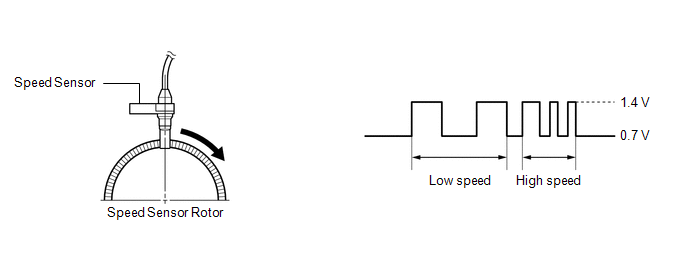

The speed sensor detects wheel speed and sends the appropriate signals to the skid control ECU (brake actuator assembly). These signals are used for brake control.

Speed sensor rotors have rows of alternating N and S magnetic poles, and their magnetic fields change when the rotors turn.

Each speed sensor detects that magnetic change and sends a pulse signal to the skid control ECU (brake actuator assembly).

HINT:

When the connectors between the speed sensor and skid control ECU (brake actuator assembly) are connected, the following waveform is output.

| DTC No. | Detection Item | DTC Detection Condition | Trouble Area | DTC Output from |

|---|---|---|---|---|

| C05121F | Right Rear Wheel Speed Sensor Circuit Intermittent | Any of the following is detected:

|

| Brake |

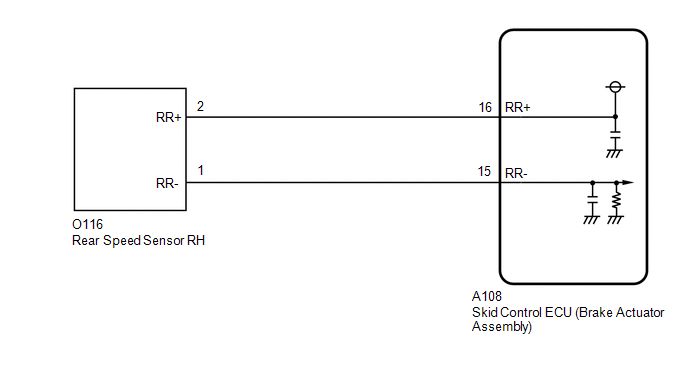

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

-

After replacing the skid control ECU (brake actuator assembly), perform "Calibration".

Click here

-

After replacing or removing and installing a speed sensor, perform Dealer Mode (Signal Check) inspection to confirm that the speed sensors are operating correctly.

Click here

-

After replacing or removing and installing a speed sensor rotor, perform Dealer Mode (Signal Check) inspection to confirm that the speed sensors are operating correctly.

Click here

PROCEDURE

| 1. | READ VALUE USING GTS (RR SPEED SENSOR VOLTAGE OPEN) |

(a) Operate the GTS to check the Data List.

Chassis > Brake > Data List| Tester Display | Measurement Item | Range | Normal Condition | Diagnostic Note |

|---|---|---|---|---|

| RR Speed Sensor Voltage Open | Rear speed sensor RH voltage open detection | Under intermittent / Normal | Under intermittent: Momentary interruption detected Normal: Momentary interruption not detected | - |

| Tester Display |

|---|

| RR Speed Sensor Voltage Open |

(b) Select the line graph display.

(c) Check for any momentary interruption in the wire harness and connector.

Click here

OK:

Normal (There are no momentary interruptions.)

NOTICE:

Perform the above inspection before removing the sensor and connector.

| NG |

| GO TO STEP 5 |

|

| 2. | READ VALUE USING GTS (RR WHEEL SPEED) |

(a) Operate the GTS to check the Data List.

Chassis > Brake > Data List| Tester Display | Measurement Item | Range | Normal Condition | Diagnostic Note |

|---|---|---|---|---|

| RR Wheel Speed | Rear wheel speed sensor RH reading | Min.: 0.0 km/h (0.0 mph) Max.: 6553.5 km/h (4072 mph) | Vehicle stopped: 0.0 km/h (0.0 mph) | When driving at constant speed: No large fluctuations |

| Tester Display |

|---|

| RR Wheel Speed |

(b) Drive the vehicle and perform a road test.

(c) Check the speed value output from the speed sensor displayed on the GTS.

HINT:

Factors that affect the indicated vehicle speed include tire size, tire pressure, and tire wear. The speed indicated on the speedometer has an allowable margin of error. This can be tested using a speedometer tester (calibrated chassis dynamometer). For details about testing and the margin of error, see the reference chart.

Click here

OK:

The speed value output from the speed sensor displayed on the GTS is similar to the speed indicated on the speedometer.

| NG |

| GO TO STEP 5 |

|

| 3. | CLEAR DTC |

(a) Operate the GTS to clear the codes.

Chassis > Brake > Clear DTCs(b) Press the DTC clear button.

(c) Turn the ignition switch off.

|

| 4. | RECONFIRM DTC |

(a) Based on the Freeze Frame Data and interview with the customer, attempt to reproduce the conditions when the malfunction occurred.

(b) Operate the GTS to read the DTCs.

Chassis > Brake > Trouble Codes(c) Check if the same DTC is output.

| Result | Proceed to |

|---|---|

| C05121F is not output | A |

| C05121F is output | B |

| A |

| USE SIMULATION METHOD TO CHECK |

| B |

| REPLACE BRAKE ACTUATOR ASSEMBLY |

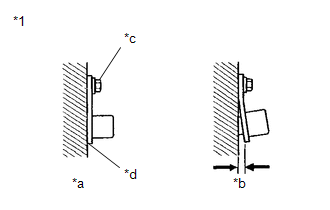

| 5. | CHECK REAR SPEED SENSOR RH INSTALLATION |

| (a) Turn the ignition switch off. |

|

(b) Check the rear speed sensor RH installation.

OK:

There is no clearance between the rear speed sensor RH and rear axle carrier sub-assembly RH.

The installation bolt is tightened properly.

Torque

8.5 N*m (87 kgf*cm, 75 in.*lbf)

| NG |

| REINSTALL OR REPLACE REAR SPEED SENSOR RH |

|

| 6. | CHECK REAR SPEED SENSOR RH AND REAR SPEED SENSOR ROTOR RH (CHECK FOR FOREIGN MATTER) |

(a) Remove the rear speed sensor RH and the component with the rear speed sensor rotor RH.

for rear speed sensor RH: Click here

for rear speed sensor rotor RH: Click here

(b) Check the rear speed sensor RH tip and rear speed sensor rotor RH.

OK:

No scratches, oil, or foreign matter on the rear speed sensor RH tip and rear speed sensor rotor RH.

NOTICE:

- If there is oil or foreign matter on the rear speed sensor RH, clean the rear speed sensor RH.

- If the rear speed sensor RH is damaged, replace the rear speed sensor RH with a new one.

- Do not use parts cleaner when cleaning the rear speed sensor rotor RH.

- If the rear speed sensor rotor RH is damaged, replace the rear speed sensor rotor RH with a new one.

HINT:

- The rear speed sensor rotor RH is incorporated into the rear axle hub and bearing assembly RH.

- If the rear speed sensor rotor RH needs to be replaced, replace it together with the rear axle hub and bearing assembly RH.

| NG |

| CLEAN OR REPLACE REAR SPEED SENSOR RH OR COMPONENT WITH REAR SENSOR ROTOR RH |

|

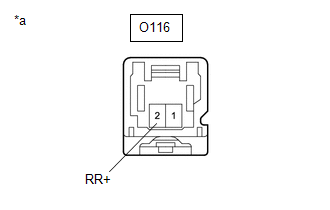

| 7. | CHECK HARNESS AND CONNECTOR (REAR SPEED SENSOR RH - BRAKE ACTUATOR ASSEMBLY) |

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors.

OK:

The connector is securely connected.

(b) Disconnect the A108 skid control ECU (brake actuator assembly) connector.

(c) Disconnect the O116 rear speed sensor RH connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| O116-2 (RR+) - A108-16 (RR+) | Always | Below 1 Ω |

| O116-2 (RR+) or A108-16 (RR+) - Body ground | Always | 10 kΩ or higher |

| O116-1 (RR-) - A108-15 (RR-) | Always | Below 1 Ω |

| O116-1 (RR-) or A108-15 (RR-) - Body ground | Always | 10 kΩ or higher |

| NG |

| REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 8. | INSPECT BRAKE ACTUATOR ASSEMBLY (SENSOR POWER SOURCE CIRCUIT) |

(a) Reconnect the A108 skid control ECU (brake actuator assembly) connector.

| (b) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

(c) Turn the ignition switch to ON.

(d) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| O116-2 (RR+) - Body ground | Ignition switch ON | 11 to 14 V |

| OK |

| REPLACE REAR SPEED SENSOR RH |

| NG |

| REPLACE BRAKE ACTUATOR ASSEMBLY |

Right Rear Wheel Speed Sensor Circuit Short to Ground or Open (C051214)

Right Rear Wheel Speed Sensor Circuit Short to Ground or Open (C051214)

DESCRIPTION Refer to DTC C05121F. Click here

DTC No. Detection Item DTC Detection Condition Trouble Area DTC Output from C051214 Right Rear Wheel Speed Sensor Circuit Short to Ground or Open An open in the speed sensor signal circuit continues for 0...

Multi-axis Acceleration Sensor Module "A" Missing Calibration (C051D54,C121054)

Multi-axis Acceleration Sensor Module "A" Missing Calibration (C051D54,C121054)

DESCRIPTION The airbag sensor assembly has a built-in yaw rate and acceleration sensor and detects the vehicle condition. The skid control ECU (brake actuator assembly) receives signals from the yaw rate and acceleration sensor (airbag sensor assembly) via CAN communication...

Other information:

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Charge Air Cooler Temperature Sensor Bank 1 Circuit Short to Battery or Open (P007A15)

DESCRIPTION Refer to DTC P007A11. Click here DTC No. Detection Item DTC Detection Condition Trouble Area MIL Note P007A15 Charge Air Cooler Temperature Sensor Bank 1 Circuit Short to Battery or Open The output voltage from the intake air temperature sensor is higher than 4...

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Turn Signal/Hazard Flasher Circuit Current Above Threshold (B150819)

DESCRIPTION This DTC is stored when the combination meter assembly detects a short in a turn signal light circuit. HINT: If there is a short in a turn signal light circuit, all of the turn signal lights in that circuit will not blink. DTC No. Detection Item DTC Detection Condition Trouble Area B150819 Turn Signal/Hazard Flasher Circuit Current Above Threshold Diagnosis Condition: Auxiliary battery voltage is 10 V or more Malfunction Status: Short in turn signal light circuit Headlight assembly Headlight unit assembly LH Headlight unit assembly RH Wire Harness LH Wire Harness RH Outer rear view mirror assembly Side turn signal light assembly LH Side turn signal light assembly RH Rear combination light assembly Rear turn signal light LED Harness or connector Combination meter assembly WIRING DIAGRAM CAUTION / NOTICE / HINT NOTICE: When replacing the combination meter assembly, always replace it with a new one...

Categories

- Manuals Home

- Toyota Yaris Owners Manual

- Toyota Yaris Service Manual

- G16e-gts (engine Mechanical)

- Power Integration No.1 System Missing Message (B235287,B235587,B235787-B235987)

- Immobilizer System

- New on site

- Most important about car

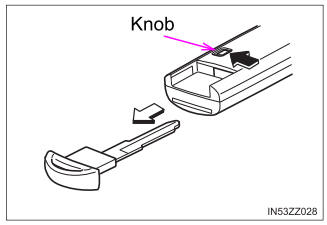

Keys

To use the auxiliary key, press the knob and pull out the auxiliary key from the smart key.