Toyota Yaris: Rear Axle Hub / Removal

REMOVAL

CAUTION / NOTICE / HINT

HINT:

- Use the same procedure for the RH side and LH side.

- The following procedure is for the LH side.

PROCEDURE

1. REMOVE REAR WHEEL

Click here

2. REMOVE REAR AXLE SHAFT NUT

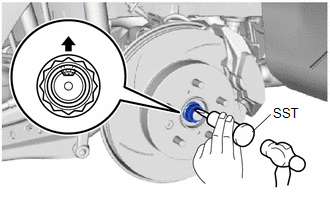

| (a) Using SST and a hammer, release the staked part of the rear axle shaft nut. SST: 09930-00010 NOTICE: Loosen the staked part of the rear axle shaft nut completely, otherwise the threads of the rear drive shaft assembly may be damaged. |

|

(b) While applying the brakes, remove the rear axle shaft nut.

3. SEPARATE REAR DISC BRAKE CALIPER ASSEMBLY

Click here

4. REMOVE PARKING BRAKE SHOE ADJUSTING HOLE PLUG

Click here

5. REMOVE REAR DISC

Click here

6. DISCONNECT REAR SPEED SENSOR

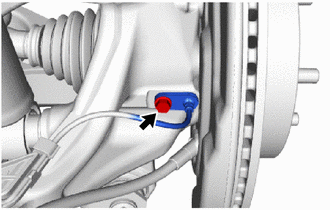

| (a) Remove the bolt and rear speed sensor from the rear axle carrier sub-assembly. NOTICE:

|

|

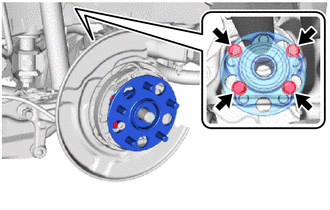

7. REMOVE REAR AXLE HUB AND BEARING ASSEMBLY

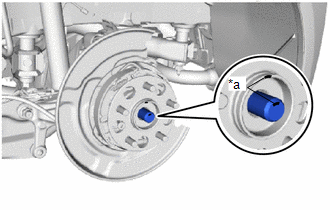

| (a) Put matchmarks on the rear drive shaft assembly and the rear axle hub and bearing assembly. |

|

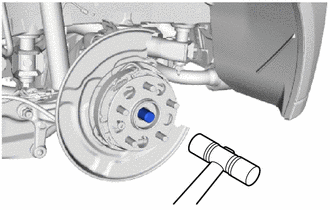

| (b) Using a plastic hammer, separate the rear drive shaft assembly from the rear axle hub and bearing assembly. NOTICE:

HINT: If it is difficult to separate the rear drive shaft assembly rear axle hub and bearing assembly, tap the end of the rear drive shaft assembly using a brass bar and a hammer. |

|

| (c) Remove the 4 bolts, rear axle hub and bearing assembly from the rear axle carrier sub-assembly. |

|

On-vehicle Inspection

On-vehicle Inspection

ON-VEHICLE INSPECTION CAUTION / NOTICE / HINT HINT:

Use the same procedure for the RH side and LH side.

The following procedure is for the LH side...

Installation

Installation

INSTALLATION CAUTION / NOTICE / HINT HINT:

Use the same procedure for the RH side and LH side.

The following procedure is for the LH side.

PROCEDURE 1...

Other information:

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Removal

REMOVAL CAUTION / NOTICE / HINT HINT: Use the same procedure for the RH and LH sides. The procedure listed below is for the LH side. PROCEDURE 1. REMOVE FRONT DOOR LOWER FRAME BRACKET GARNISH Click here 2. REMOVE MULTIPLEX NETWORK MASTER SWITCH ASSEMBLY WITH FRONT ARMREST BASE UPPER PANEL (for Driver Side) Click here 3...

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Manifold Absolute Pressure / Barometric Pressure Sensor Circuit Short to Battery or Open (P010515)

DESCRIPTION Refer to DTC P010511. Click here DTC No. Detection Item DTC Detection Condition Trouble Area MIL Note P010515 Manifold Absolute Pressure / Barometric Pressure Sensor Circuit Short to Battery or Open The No. 1 turbo pressure sensor output voltage is higher than 4...

Categories

- Manuals Home

- Toyota Yaris Owners Manual

- Toyota Yaris Service Manual

- Power Integration No.1 System Missing Message (B235287,B235587,B235787-B235987)

- How to use USB mode

- Diagnostic Trouble Code Chart

- New on site

- Most important about car

Fuel Gauge

The fuel gauge shows approximately how much fuel is remaining in the tank when the ignition is switched ON. We recommend keeping the tank over 1/4 full.