Toyota Yaris: Front Speed Sensor / Removal

REMOVAL

CAUTION / NOTICE / HINT

HINT:

- Use the same procedure for the RH side and LH side.

- The following procedure is for the LH side.

- The front speed sensor rotor is a component of the front axle hub sub-assembly. If the front speed sensor rotor is malfunctioning, replace the front axle hub sub-assembly.

PROCEDURE

1. REMOVE FRONT WHEEL

Click here

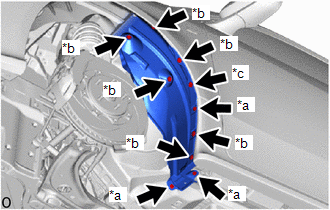

2. SEPARATE FRONT FENDER LINER

| (a) Remove the 6 clips, 3 screws and grommet to separate the front fender liner. |

|

3. REMOVE FRONT SPEED SENSOR

(a) Turn back the front fender liner.

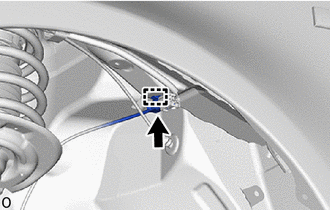

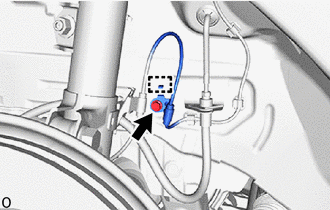

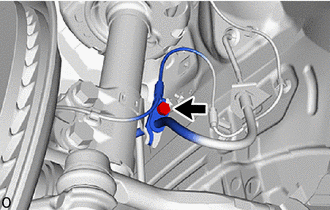

| (b) Disconnect the connector. |

|

(c) Disengage the clamp from the vehicle body.

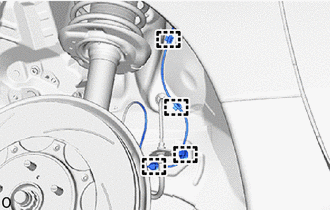

| (d) Disengage the 4 clamps from the vehicle body. |

|

| (e) Remove the bolt and hook to separate the front speed sensor. |

|

| (f) Remove the bolt and separate the front flexible hose and front speed sensor clamp from the front shock absorber assembly. |

|

| (g) Disengage the clamp from the front shock absorber assembly. |

|

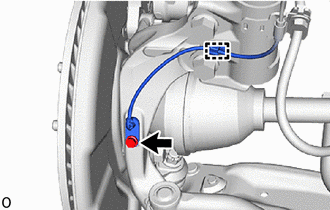

(h) Remove the bolt and front speed sensor from the steering knuckle.

NOTICE:

- Keep the tip of the front speed sensor and installation hole free of foreign matter.

- Do not rotate or apply excessive force to the front speed sensor when removing it from the steering knuckle. Rotating or applying excessive force may result in damage to the front speed sensor.

Installation

Installation

INSTALLATION CAUTION / NOTICE / HINT HINT:

Use the same procedure for the RH side and LH side.

The following procedure is for the LH side.

The front speed sensor rotor is a component of the front axle hub sub-assembly...

Other information:

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Data List / Active Test

DATA LIST / ACTIVE TEST DATA LIST NOTICE: In the table below, the values listed under Normal Condition are reference values. Do not depend solely on these reference values when deciding whether a part is faulty or not. HINT: Using the GTS to read the Data List allows the values or states of switches, sensors, actuators and other items to be read without removing any parts...

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Power Distribution Box System Internal Failure (B235504)

DESCRIPTION This DTC is output when the power distribution box assembly detects a Internal circuit error. DTC No. Detection Item DTC Detection Condition Trouble Area B235504 Power Distribution Box System Internal Failure Microcomputer abnormality AD circuit trouble The load drive output open or short trouble Power distribution box assembly WIRING DIAGRAM Click here CAUTION / NOTICE / HINT NOTICE: When using the GTS with the ignition switch off to troubleshoot: Connect the GTS to the vehicle, and turn a courtesy switch on and off at 1...

Categories

- Manuals Home

- Toyota Yaris Owners Manual

- Toyota Yaris Service Manual

- To Set Speed

- Removal

- Diagnostic Trouble Code Chart

- New on site

- Most important about car

Fuel Gauge

The fuel gauge shows approximately how much fuel is remaining in the tank when the ignition is switched ON. We recommend keeping the tank over 1/4 full.