Toyota Yaris: Windshield Glass / Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during the windshield glass removal/installation are shown below.

Necessary Procedure After Parts Removed/Installed/Replaced| Replacement Part | Necessary Procedure | Effect/Inoperative Function when Necessary Procedures are not Performed | Link |

|---|---|---|---|

| Windshield glass (Including removal and installation) | Adjust forward recognition camera |

| One Time Recognition:

Sequential Recognition:

Driving Adjustment:

|

NOTICE:

- When replacing the windshield glass of a vehicle equipped with a forward recognition camera, make sure to use a Toyota genuine part. If a non-Toyota genuine part is used, the forward recognition camera may not be able to be installed due to a missing bracket. Also, the dynamic radar cruise control system, lane tracing assist system, pre-collision system, front camera system or auto high beam system may not operate properly due to a difference in the transmissivity or black ceramic border.

- Make sure to use Toyota Genuine Windshield Glass Adhesive (High Modulus Type) or equivalent.

PROCEDURE

1. REMOVE WINDSHIELD WIPER MOTOR AND LINK

Click here

.gif)

2. REMOVE FORWARD RECOGNITION WITH HEATER HOOD SUB-ASSEMBLY (w/ Pre-collision System)

Click here

.gif)

3. REMOVE RAIN SENSOR

Click here

.gif)

4. REMOVE INNER REAR VIEW MIRROR ASSEMBLY

Click here

.gif)

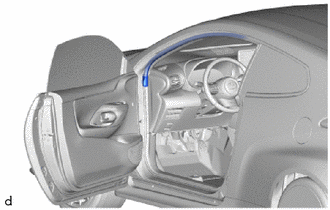

5. SEPARATE FRONT DOOR OPENING TRIM WEATHERSTRIP LH

| (a) Separate the front door opening trim weatherstrip LH. |

|

6. SEPARATE FRONT DOOR OPENING TRIM WEATHERSTRIP RH

HINT:

Use the same procedure as for the LH side.

7. REMOVE FRONT PILLAR GARNISH LH

Click here

.gif)

8. REMOVE FRONT PILLAR GARNISH RH

HINT:

Use the same procedure as for the LH side.

9. REMOVE MAP LIGHT ASSEMBLY

Click here

.gif)

10. REMOVE VISOR ASSEMBLY LH

Click here

.gif)

11. REMOVE VISOR ASSEMBLY RH

HINT:

Use the same procedure as for the LH side.

12. REMOVE VISOR HOLDER LH

Click here

.gif)

13. REMOVE VISOR HOLDER RH

HINT:

Use the same procedure as for the LH side.

14. REMOVE ASSIST GRIP COVER

Click here

.gif)

15. REMOVE ASSIST GRIP SUB-ASSEMBLY

Click here

.gif)

16. SEPARATE ROOF HEADLINING

| (a) Slightly lower the front section of the roof headlining so that the windshield glass can be removed. NOTICE: Do not damage the roof headlining or vehicle interior. HINT: It is not necessary to completely remove the roof headlining. |

|

17. REMOVE WINDSHIELD GLASS

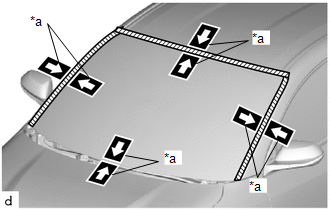

(a) Apply protective tape to the area around the installation position of the windshield glass on the vehicle body to prevent it from being scratched.

.png) | Protective Tape |

(b) When reusing the windshield glass:

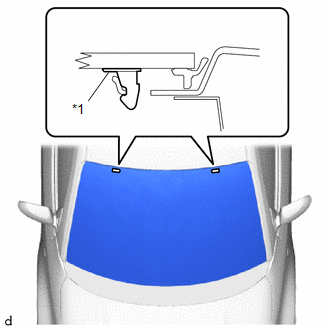

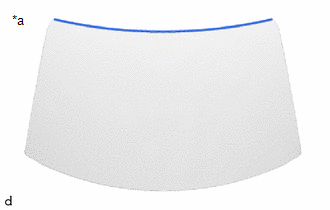

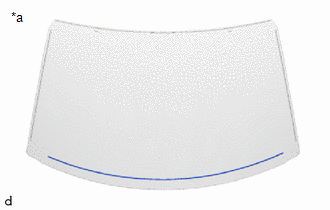

| (1) Place matchmarks on the windshield glass and vehicle body at the locations indicated in the illustration. |

|

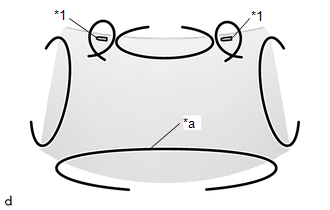

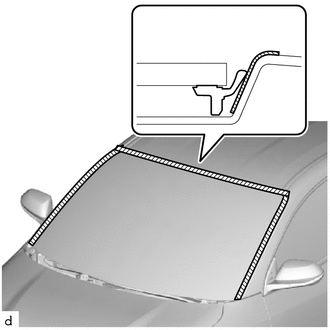

| (c) Pass a piano wire between the vehicle body and windshield glass from the interior. |

|

(d) Tie both wire ends to wooden blocks or similar objects that can serve as handles.

(e) Cut the adhesive by pulling the piano wire around the windshield glass.

NOTICE:

- When separating the windshield glass, be careful not to damage the paint or interior and exterior ornaments.

- To prevent the instrument panel safety pad sub-assembly from being scratched when removing the windshield glass, place a plastic sheet between the piano wire and instrument panel safety pad sub-assembly.

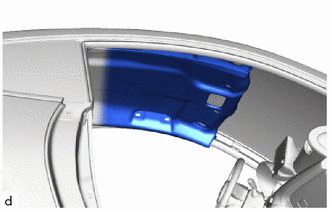

| (f) Disengage the windshield glass stoppers. NOTICE:

|

|

(g) Using suction cups, remove the windshield glass.

NOTICE:

- Be careful not to drop the windshield glass.

- Leave as much adhesive on the vehicle body as possible when removing the windshield glass.

18. REMOVE WINDSHIELD OUTSIDE MOULDING

(a) When reusing the windshield glass:

| (1) Using a scraper, remove the windshield outside moulding. NOTICE:

|

|

19. REMOVE NO. 2 WINDOW GLASS ADHESIVE DAM

(a) When reusing the windshield glass:

| (1) Using a scraper, remove the No. 2 window glass adhesive dam. NOTICE:

|

|

20. REMOVE WINDOW GLASS ADHESIVE DAM

(a) When reusing the windshield glass:

| (1) Using a scraper, remove the 2 window glass adhesive dams. NOTICE:

|

|

21. REMOVE WINDSHIELD GLASS STOPPER

(a) When reusing the windshield glass:

| (1) Using a scraper, remove the 2 windshield glass stoppers. NOTICE:

|

|

Components

Components

COMPONENTS ILLUSTRATION

*1 FRONT DOOR OPENING TRIM WEATHERSTRIP LH *2 FRONT DOOR OPENING TRIM WEATHERSTRIP RH *3 FRONT PILLAR GARNISH LH *4 FRONT PILLAR GARNISH RH *5 FRONT PILLAR GARNISH CLIP - - ● Non-reusable part - - ILLUSTRATION

*A w/ Pre-collision System - - *1 VISOR ASSEMBLY LH *2 VISOR ASSEMBLY RH *3 VISOR HOLDER LH *4 VISOR HOLDER RH *5 ASSIST GRIP COVER *6 ASSIST GRIP SUB-ASSEMBLY *7 ROOF HEADLINING *8 FORWARD RECOGNITION WITH HEATER HOOD SUB-ASSEMBLY ILLUSTRATION

*1 WINDSHIELD GLASS *2 WINDSHIELD OUTSIDE MOULDING *3 NO...

Installation

Installation

INSTALLATION CAUTION / NOTICE / HINT NOTICE:

When replacing the windshield glass of a vehicle equipped with a forward recognition camera, make sure to use a Toyota genuine part...

Other information:

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Freeze Frame Data

FREEZE FRAME DATA DESCRIPTION The ECM records vehicle and driving condition information as Freeze Frame Data the moment a DTC is stored. When troubleshooting, Freeze Frame Data can be helpful in determining whether the vehicle was moving or stationary, whether the engine was warmed up or not, whether the air fuel ratio was lean or rich, as well as other data recorded at the time of a malfunction...

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: How To Proceed With Troubleshooting

CAUTION / NOTICE / HINT HINT: Use the following procedure to troubleshoot the power steering system. *: Use the GTS. PROCEDURE 1. VEHICLE BROUGHT TO WORKSHOP NEXT 2. INSPECT AUXILIARY BATTERY (a) Turn the ignition switch off...

Categories

- Manuals Home

- Toyota Yaris Owners Manual

- Toyota Yaris Service Manual

- Key Battery Replacement

- Fuse Panel Description

- Brake System Control Module "A" System Voltage System Voltage Low (C137BA2)

- New on site

- Most important about car

Front Seat Belt Pretensioners

The front seat belt pretensioners are designed to deploy in moderate or severe frontal, near frontal collisions.

In addition, the pretensioners operate when a side collision or a rollover accident is detected. The pretensioners operate differently depending on what types of air bags are equipped. For more details about the seat belt pretensioner operation, refer to the SRS Air Bag Deployment Criteria.