Toyota Yaris: Fuel Main Valve / Removal

REMOVAL

CAUTION / NOTICE / HINT

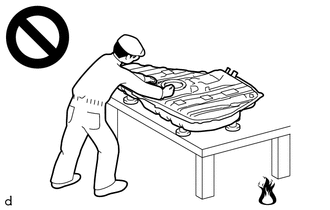

CAUTION:

-

Never perform work on fuel system components near any possible ignition sources.

- Vaporized fuel could ignite, resulting in a serious accident.

-

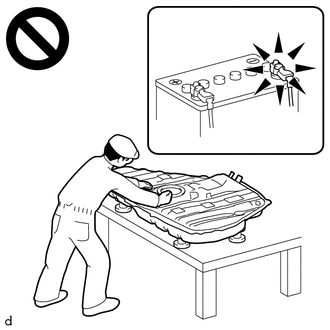

Do not perform work on fuel system components without first disconnecting the cable from the negative (-) auxiliary battery terminal.

- Sparks could cause vaporized fuel to ignite, resulting in a serious accident.

NOTICE:

- After the ignition switch is turned off, the radio and display receiver assembly records various types of memory and settings. As a result, after turning the ignition switch off, make sure to wait at least 120 seconds before disconnecting the cable from the negative (-) auxiliary battery terminal.

-

This procedure includes the removal of small-head bolts. Refer to Small-Head Bolts of Basic Repair Hint to identify the small-head bolts.

Click here

HINT:

When the cable is disconnected/reconnected to the auxiliary battery terminal, systems temporarily stop operating. However, each system has a function that completes learning the first time the system is used.

-

Learning completes when vehicle is driven

Effect/Inoperative Function When Necessary Procedures are not Performed

Necessary Procedures

Link

Lane tracing assist system

Drive the vehicle straight ahead at 35 km/h (22 mph) or more for 5 second or more.

Pre-collision system

Stop and start system

Drive the vehicle until stop and start control is permitted (approximately 5 to 60 minutes)

-

Learning completes when vehicle is operated normally

Effect/Inoperative Function When Necessary Procedures are not Performed

Necessary Procedures

Link

Power door lock control system

- Back door opener

Perform door unlock operation with door control switch or electrical key transmitter sub-assembly switch.

Air conditioning system

After the ignition switch is turned to ON, the servo motor standard position is recognized.

-

PROCEDURE

1. REMOVE FUEL SUCTION WITH PUMP AND GAUGE TUBE ASSEMBLY

Click here

2. REMOVE FUEL SENDER GAUGE ASSEMBLY

Click here

3. REMOVE FUEL MAIN VALVE ASSEMBLY

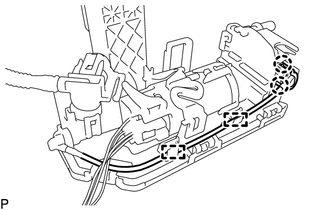

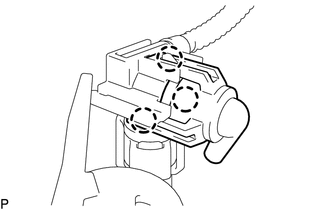

| (a) Detach the 2 claws and 2 clamps and disconnect the fuel suction tube from the fuel suction with pump and gauge tube assembly. |

|

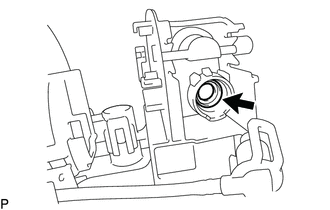

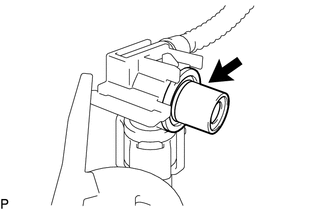

| (b) Remove the O-ring from the fuel suction with pump and gauge tube assembly. |

|

| (c) Detach the 4 claws and disconnect the sub-assembly support from the fuel suction with pump and gauge tube assembly. |

|

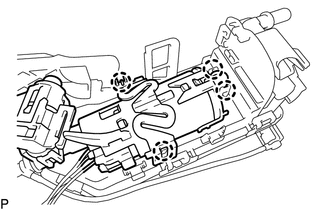

| (d) Detach the 3 claws and remove the No. 3 fuel suction support from the fuel suction with pump and gauge tube assembly. |

|

| (e) Remove the fuel main valve assembly from the fuel suction with pump and gauge tube assembly. |

|

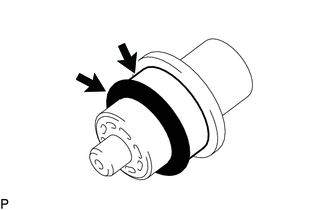

| (f) Remove the O-ring and spacer from the fuel main valve assembly. |

|

Components

Components

COMPONENTS ILLUSTRATION

*1 FUEL MAIN VALVE ASSEMBLY *2 FUEL SENDER GAUGE ASSEMBLY *3 FUEL SUCTION WITH PUMP AND GAUGE TUBE ASSEMBLY *4 NO...

Installation

Installation

INSTALLATION PROCEDURE 1. INSTALL FUEL MAIN VALVE ASSEMBLY (a) Apply gasoline to a new O-ring. (b) Install the spacer and O-ring to the fuel main valve assembly...

Other information:

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Inspection

INSPECTION PROCEDURE 1. INSPECT AUTO HIGH BEAM SWITCH (a) Check the resistance. (1) Measure the resistance according to the value(s) in the table below. Standard Resistance: Tester Connection Condition Specified Condition H47-5 (+B) - H47-2 (E) Auto high beam switch off 10 kΩ or higher H47-5 (+B) - H47-2 (E) Auto high beam switch on Below 1 Ω If the result is not as specified, replace the auto high beam switch...

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Invalid Data Received from ECM/PCM "A" Invalid Serial Data Received (U040181)

DESCRIPTION If the ECM cannot recognize the millimeter wave radar sensor assembly. DTC U040181 is stored. DTC No. Detection Item DTC Detection Condition Trouble Area DTC Output from U040181 Invalid Data Received from ECM/PCM "A" Invalid Serial Data Received Approximately 17 seconds or more after the ignition switch is turned to ON, the ECM cannot recognize the millimeter wave radar sensor assembly for approximately 5 seconds or more...

Categories

- Manuals Home

- Toyota Yaris Owners Manual

- Toyota Yaris Service Manual

- Fuse Panel Description

- Headlights

- G16e-gts (engine Mechanical)

- New on site

- Most important about car

Break-In Period

No special break-in is necessary, but a few precautions in the first 600 miles (1,000 km) may add to the performance, economy, and life of the vehicle.

Do not race the engine. Do not maintain one constant speed, either slow or fast, for a long period of time. Do not drive constantly at full-throttle or high engine rpm for extended periods of time. Avoid unnecessary hard stops. Avoid full-throttle starts.