Toyota Yaris: Oil Pump / Installation

INSTALLATION

PROCEDURE

1. INSTALL TIMING CHAIN COVER OIL SEAL

Click here

2. INSTALL TIMING CHAIN COVER ASSEMBLY

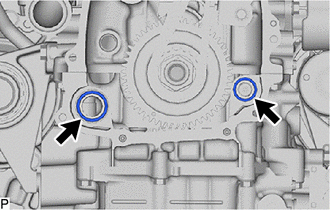

| (a) Install 2 new O-rings to the cylinder block sub-assembly. |

|

(b) Clean the contact surfaces of the timing chain cover assembly, oil pan sub-assembly and cylinder block sub-assembly, and confirm that no oil, moisture, or other foreign matter is on the surfaces.

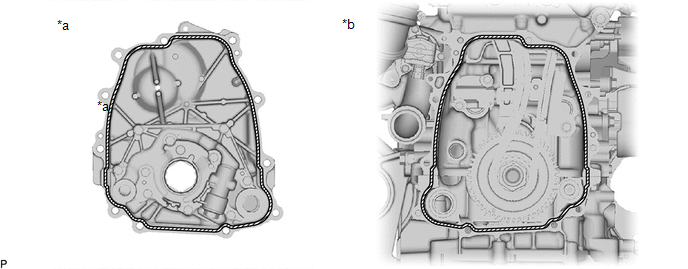

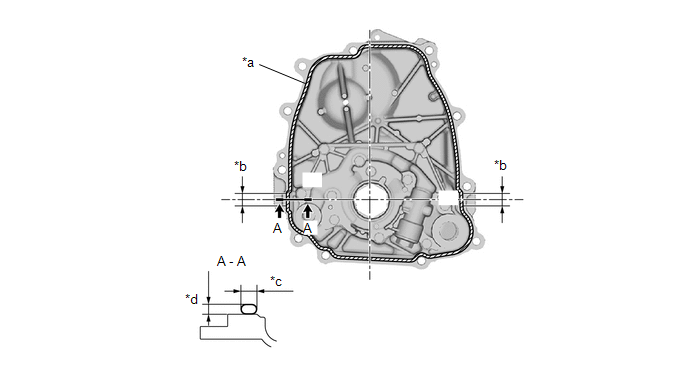

| *a | Timing Chain Cover Assembly Side | *b | Engine Assembly Side |

(c) Clean the contact surfaces of the timing chain cover assembly, oil pan sub-assembly and cylinder block sub-assembly, and confirm that no oil, moisture, or other foreign matter is on the surfaces.

| *a | 2.5 to 3.5 mm (0.0984 to 0.138 in.) | *b | 10 mm (0.394 in.) |

| *c | 4.0 to 6.0 mm (0.157 to 0.236 in.) | *d | 3.0 to 4.0 mm (0.118 to 0.157 in.) |

| Seal Packing | - | - |

Seal Packing:

Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

NOTICE:

- Clean the surfaces with non-residue solvent before applying seal packing.

- Install the timing chain cover assembly within 3 minutes and tighten the bolts within 10 minutes of applying seal packing.

- Do not add oil for at least 2 hours after installation.

- Do not start the engine for at least 2 hours after installation.

- Make sure that the diameter at the start and end of each line of seal packing is 5 +/- 2 mm (0.197 +/- 0.0787 in.).

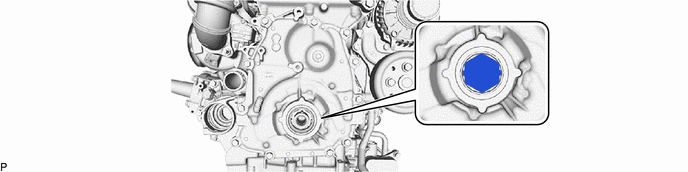

(d) Align the oil pump drive rotor groove of the timing chain cover assembly.

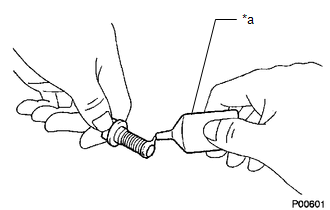

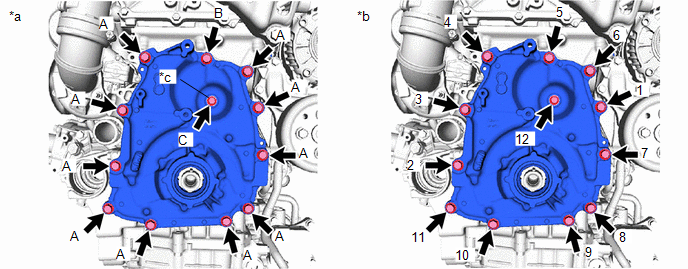

| (e) Apply adhesive to 5 and a half threads or more of the end of the bolts (A, B). Adhesive: Toyota Genuine Adhesive 1344, Three Bond 1344 or equivalent |

|

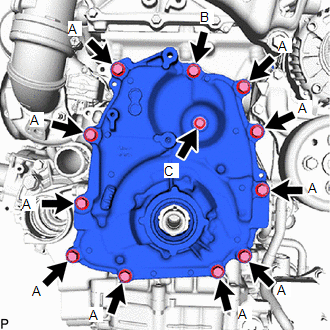

| (f) Temporarily install the timing chain cover assembly with the 11 bolts and a new bolt (C) and seal washer. Bolt Length:

|

|

(g) Install the timing chain cover assembly with the 11 bolts and a new bolt (C) and seal washer in the order shown in the illustration.

| *a | Torque | *b | Bolt Tightening Order |

| *c | Seal Washer | - | - |

Torque:

Bolt (A), (B) :

21 N·m {214 kgf·cm, 15 ft·lbf}

Bolt (C) :

10 N·m {102 kgf·cm, 7 ft·lbf}

3. INSTALL CRANKSHAFT PULLEY

Click here

4. INSTALL TIMING GEAR COVER INSULATOR

(a) Install the timing gear cover insulator to the timing chain cover assembly.

5. INSTALL V-RIBBED BELT TENSIONER ASSEMBLY

Click here

6. INSTALL ENGINE WIRE

(a) Install the engine wire to the timing chain cover assembly with the bolt.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

7. INSTALL NO. 2 AIR HOSE

(a) Install the No. 2 air hose to the turbocharger sub-assembly and tighten the hose clamp.

Torque:

6.0 N·m {61 kgf·cm, 53 in·lbf}

8. INSTALL NO. 1 AIR TUBE

(a) Install the 2 bolts.

Torque:

7.0 N·m {71 kgf·cm, 62 in·lbf}

(b) Install the No. 1 air tube to the No. 2 air hose, No. 3 air hose and tighten the hose clamp.

Torque:

6.0 N·m {61 kgf·cm, 53 in·lbf}

9. INSTALL COMPRESSOR ASSEMBLY WITH PULLEY

Click here

10. INSTALL FAN AND GENERATOR V BELT

Click here

11. INSTALL NO. 1 ENGINE UNDER COVER ASSEMBLY

Click here

12. INSTALL ENGINE UNDER COVER RH

Click here

13. INSTALL FRONT WHEELS

Click here

Removal

Removal

REMOVAL PROCEDURE 1. REMOVE FRONT WHEELS Click here

2. REMOVE ENGINE UNDER COVER RH Click here

3. REMOVE NO. 1 ENGINE UNDER COVER ASSEMBLY Click here

4...

Other information:

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: On-vehicle Inspection

ON-VEHICLE INSPECTION CAUTION / NOTICE / HINT CAUTION: To prevent burns, do not touch the engine, exhaust manifold or other high temperature components while the engine is hot. To prevent burns, do not remove the oil pressure and temperature sensor while the engine is hot...

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Removal

REMOVAL CAUTION / NOTICE / HINT CAUTION: Never perform work on fuel system components near any possible ignition sources. Vaporized fuel could ignite, resulting in a serious accident. Do not perform work on fuel system components without first disconnecting the cable from the negative (-) auxiliary battery terminal...

Categories

- Manuals Home

- Toyota Yaris Owners Manual

- Toyota Yaris Service Manual

- Removal

- Brake System Control Module "A" System Voltage System Voltage Low (C137BA2)

- Immobilizer System

- New on site

- Most important about car

Front Seat Belt Pretensioners

The front seat belt pretensioners are designed to deploy in moderate or severe frontal, near frontal collisions.

In addition, the pretensioners operate when a side collision or a rollover accident is detected. The pretensioners operate differently depending on what types of air bags are equipped. For more details about the seat belt pretensioner operation, refer to the SRS Air Bag Deployment Criteria.