Toyota Yaris: Cooling Fan System / Cooling Fan Circuit

DESCRIPTION

The ECM calculates an appropriate cooling fan speed based on the engine coolant temperature, air conditioning switch status, refrigerant pressure, engine speed and vehicle speed, and sends a signal to the cooling fan ECU (fan with motor assembly). The cooling fan ECU (fan with motor assembly) steplessly control the speed of the cooling fan based on the duty cycle signal sent from the ECM. By sending signals to the cooling fan ECU (fan with motor assembly) in accordance with the driving conditions and by controlling the cooling fan speed optimally with the ECM, both high cooling performance and quietness are ensured.

WIRING DIAGRAM

Click here

CAUTION / NOTICE / HINT

NOTICE:

- Inspect the fuses for circuits related to this system before performing the following procedure.

-

Make sure to perform the necessary procedures (adjustment, calibration, initialization, or registration) after parts related to the cooling fan system have been removed/installed or replaced.

Click here

PROCEDURE

| 1. | PERFORM ACTIVE TEST USING GTS (CONTROL THE ENGINE COOLING FAN DUTY RATIO) |

(a) Connect the GTS to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the GTS on.

(d) Enter the following menus: Powertrain / Engine / Active Test / Control the Engine Cooling Fan Duty Ratio.

Powertrain > Engine > Active Test| Tester Display |

|---|

| Control the Engine Cooling Fan Duty Ratio |

(e) Check the operation of the cooling fan while operating it using the GTS.

OK:

| GTS Operation | Fan Operation |

|---|---|

| 30 - 100% | Cooling fan operates |

| 0% | Cooling fan stops |

| Result | Proceed to |

|---|---|

| OK | A |

| Cooling fan does not operate | B |

| Cooling fan does not stop | C |

| A |

| PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

| C |

| GO TO STEP 8 |

|

| 2. | CHECK HARNESS AND CONNECTOR (FAN WITH MOTOR ASSEMBLY - ECM) |

(a) Disconnect the A45 fan with motor assembly connector.

(b) Disconnect the A106 ECM connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| A45-3 (SI) or A106-32 (RFC) - Body ground | Always | 10 kΩ or higher |

| NG |

| REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 3. | INSPECT ECM (RFC TERMINAL) |

(a) Disconnect the A45 fan with motor assembly connector.

(b) Connect the GTS to the DLC3.

(c) Turn the ignition switch to ON.

(d) Turn the GTS on.

(e) Enter the following menus: Powertrain / Engine / Active Test / Control the Engine Cooling Fan Duty Ratio.

Powertrain > Engine > Active Test| Tester Display |

|---|

| Control the Engine Cooling Fan Duty Ratio |

(f) Operate the cooling fan motor (fan with motor assembly) using the Active Test function and measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | GTS Operation | Specified Condition |

|---|---|---|

| A45-3 (SI) - Body ground | Before Active Test (0%) → During Active Test (100%) | Before Active Test (0%): Resistance is stable → During Active Test (100%): Resistance fluctuates* |

HINT:

*: Using the Active Test, duty control of the transistors in the ECM will be performed. Due to the duty control, resistance of the RFC terminal will be unstable during the Active Test. If the resistance is stable before the Active Test and fluctuates while performing the Active Test, it can be determined that the transistor is operating. If the transistor does not operate during the Active Test, the ECM may be malfunctioning.

| NG |

| REPLACE ECM |

|

| 4. | CHECK HARNESS AND CONNECTOR (FAN WITH MOTOR ASSEMBLY POWER SOURCE) |

(a) Disconnect the A45 fan with motor assembly connector.

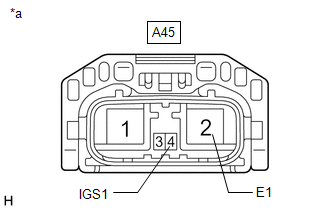

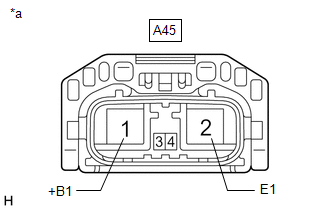

| *a | Front view of wire harness connector (to Fan with Motor Assembly) |

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| A45-1 (+B1) - A45-2 (E1) | Always | 11 to 14 V |

| NG |

| GO TO STEP 7 |

|

| 5. | CHECK HARNESS AND CONNECTOR (FAN WITH MOTOR ASSEMBLY POWER SOURCE) |

(a) Disconnect the A45 fan with motor assembly connector.

(b) Turn the ignition switch to ON.

| (c) Measure the voltage according to the value(s) in the table below. Standard Voltage:

|

|

| OK |

| REPLACE FAN |

|

| 6. | CHECK HARNESS AND CONNECTOR (FAN WITH MOTOR ASSEMBLY - EFI-MAIN NO. 1 RELAY) |

(a) Disconnect the A45 fan with motor assembly connector.

(b) Remove the EFI-MAIN NO. 1 relay from the No. 1 engine room relay block and No. 1 junction block assembly.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| A45-4 (IGS1) - 5 (EFI-MAIN NO. 1 relay) | Always | Below 1 Ω |

| OK |

| CHECK ECM POWER SOURCE CIRCUIT |

| NG |

| REPAIR OR REPLACE HARNESS OR CONNECTOR |

| 7. | CHECK HARNESS AND CONNECTOR (FAN WITH MOTOR ASSEMBLY - BODY GROUND) |

(a) Disconnect the A45 fan with motor assembly connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| A45-2 (E1) - Body ground | Always | Below 1 Ω |

| OK |

| REPAIR OR REPLACE HARNESS OR CONNECTOR (FAN WITH MOTOR ASSEMBLY - BATTERY) |

| NG |

| REPAIR OR REPLACE HARNESS OR CONNECTOR |

| 8. | INSPECT ECM (RFC TERMINAL) |

(a) Disconnect the A45 fan with motor assembly connector.

(b) Connect the GTS to the DLC3.

(c) Turn the ignition switch to ON.

(d) Turn the GTS on.

(e) Enter the following menus: Powertrain / Engine / Active Test / Control the Engine Cooling Fan Duty Ratio.

Powertrain > Engine > Active Test| Tester Display |

|---|

| Control the Engine Cooling Fan Duty Ratio |

(f) Operate the cooling fan motor (fan with motor assembly) using the Active Test function and measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | GTS Operation | Specified Condition |

|---|---|---|

| A45-3 (SI) - Body ground | Before Active Test (0%) → During Active Test (100%) | Before Active Test (0%): Resistance is stable → During Active Test (100%): Resistance fluctuates* |

HINT:

*: Using the Active Test, duty control of the transistors in the ECM will be performed. Due to the duty control, resistance of the RFC terminal will be unstable during the Active Test. If the resistance is stable before the Active Test and fluctuates while performing the Active Test, it can be determined that the transistor is operating. If the transistor does not operate during the Active Test, the ECM may be malfunctioning.

| OK |

| REPLACE FAN |

|

| 9. | CHECK HARNESS AND CONNECTOR (FAN WITH MOTOR ASSEMBLY - ECM) |

(a) Disconnect the A45 fan with motor assembly connector.

(b) Disconnect the A106 ECM connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| A45-3 (SI) - A106-32 (RFC) | Always | Below 1 Ω |

| OK |

| REPLACE ECM |

| NG |

| REPAIR OR REPLACE HARNESS OR CONNECTOR |

On-vehicle Inspection

On-vehicle Inspection

ON-VEHICLE INSPECTION PROCEDURE 1. INSPECT COOLING FAN SYSTEM CAUTION: To prevent injury due to contact with an operating cooling fan, keep your hands and clothing away from the cooling fan when inspecting the cooling fan system...

Cooling System

Cooling System

On-vehicle InspectionON-VEHICLE INSPECTION CAUTION / NOTICE / HINT CAUTION: Do not remove the radiator cap sub-assembly while the engine and radiator assembly are still hot...

Other information:

Toyota Yaris XP210 (2020-2026) Owner's Manual: Bright-Metal Maintenance

Use tar remover to remove road tar and insects. Never do this with a knife or similar tool. To prevent corrosion on bright-metal surfaces, apply wax or chrome preservative and rub it to a high luster. During cold weather or in coastal areas, cover bright-metal parts with a coating of wax or preservative heavier than usual...

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Generator Control Circuit Internal Electronic Failure (P062049)

DESCRIPTION The alternator performs self-diagnosis of its internal circuits to detect malfunctions (open or short circuits). The ECM receives the result via LIN communication and stores a DTC. DTC No. Detection Item DTC Detection Condition Trouble Area MIL Note P062049 Generator Control Circuit Internal Electronic Failure All of the following conditions are met (1 trip detection logic): Ignition switch ON...

Categories

- Manuals Home

- Toyota Yaris Owners Manual

- Toyota Yaris Service Manual

- Maintenance

- Key Battery Replacement

- Engine Start Function When Key Battery is Dead

- New on site

- Most important about car

Turning the Engine Off

Stop the vehicle completely. Manual transaxle: Shift into neutral and set the parking brake.Automatic transaxle: Shift the selector lever to the P position and set the parking brake.

Press the push button start to turn off the engine. The ignition position is off.