Toyota Yaris: Clutch System / Bleeding

BLEEDING

CAUTION / NOTICE / HINT

NOTICE:

Wash off clutch fluid immediately if it comes in contact with any painted surface.

HINT:

- If any work is performed on the clutch system or if air in the clutch lines is suspected, bleed air from the clutch hydraulic system.

- In case of clutch fluid replacement, make sure that the old fluid is replaced in the clutch line between the reservoir and the bleeder before bleeding.

PROCEDURE

1. REMOVE CENTER COWL TOP VENTILATOR LOUVER

Click here

2. REMOVE BRAKE MASTER CYLINDER RESERVOIR FILLER CAP ASSEMBLY

Click here

3. FILL RESERVOIR WITH BRAKE FLUID

Click here

4. BLEED CLUTCH LINE

| (a) Remove the bleeder plug cap. |

|

(b) Connect a vinyl tube to the bleeder plug.

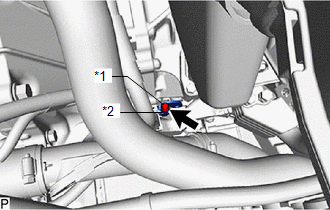

(c) Depress the clutch pedal 5 times, and then loosen the bleeder plug while the pedal is depressed.*1

(d) When fluid no longer comes out, tighten the bleeder plug, and then release the clutch pedal.*2

(e) Repeat steps *1 and *2 until all the air in the brake fluid is completely bled out.

NOTICE:

Add brake fluid to keep the level between the MIN and MAX lines of the reservoir while replacing the brake fluid.

(f) Check that all the air has been bled from the clutch line.

(g) Tighten the bleeder plug.

Torque:

8.4 N·m {86 kgf·cm, 74 in·lbf}

(h) Depress the clutch pedal 10 times or more and confirm its operation.

NOTICE:

This must be performed before the engine is started.

(i) Install the bleeder plug cap.

5. INSPECT FOR BRAKE FLUID LEAK

6. INSPECT BRAKE FLUID LEVEL IN RESERVOIR

Click here

7. INSTALL BRAKE MASTER CYLINDER RESERVOIR FILLER CAP ASSEMBLY

Click here

8. INSTALL CENTER COWL TOP VENTILATOR LOUVER

Click here

Problem Symptoms Table

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE HINT: Use the table below to help determine the cause of problem symptoms. If multiple suspected areas are listed, the potential causes of the symptoms are listed in order of probability in the "Suspected Area" column of the table...

Clutch Unit

Clutch Unit

..

Other information:

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Removal

REMOVAL CAUTION / NOTICE / HINT HINT: When the cable is disconnected / reconnected to the auxiliary battery terminal, systems temporarily stop operating. However, each system has a function that completes learning the first time the system is used. Learning completes when vehicle is driven Effect/Inoperative Function When Necessary Procedures are not Performed Necessary Procedures Link Lane tracing assist system Drive the vehicle straight ahead at 35 km/h (22 mph) or more for 5 second or more...

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: How To Proceed With Troubleshooting

HOW TO PROCEED WITH TROUBLESHOOTING OPERATION FLOW HINT: Perform troubleshooting in accordance with the procedure below. The following is an outline of basic troubleshooting procedure. Confirm the troubleshooting procedure for the circuit you are working on before beginning troubleshooting...

Categories

- Manuals Home

- Toyota Yaris Owners Manual

- Toyota Yaris Service Manual

- Power Integration No.1 System Missing Message (B235287,B235587,B235787-B235987)

- Immobilizer System

- Engine & Hybrid System

- New on site

- Most important about car

Front Seat Belt Pretensioners

The front seat belt pretensioners are designed to deploy in moderate or severe frontal, near frontal collisions.

In addition, the pretensioners operate when a side collision or a rollover accident is detected. The pretensioners operate differently depending on what types of air bags are equipped. For more details about the seat belt pretensioner operation, refer to the SRS Air Bag Deployment Criteria.