Toyota Yaris: Front Wheel Alignment / Adjustment

ADJUSTMENT

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after completing the front wheel alignment procedure are shown below.

Necessary Procedures After Procedure Performed| Replacement Part or Procedure | Necessary Procedure | Effect/Inoperative when not Performed | Link |

|---|---|---|---|

| Front wheel alignment adjustment | ECU Data Initialization | Active torque split AWD system |

|

| Calibration |

|

|

PROCEDURE

1. INSPECT TIRES

Click here

2. MEASURE VEHICLE HEIGHT

NOTICE:

- Before inspecting the wheel alignment, first inspect the vehicle height.

- Be sure to perform measurement on a level surface.

- If it is necessary to go under the vehicle for measurement, confirm that the parking brake is applied and the vehicle is secured with chocks.

- Inspect while the vehicle is unloaded.

- The standard value shown here is a value that is used for performing a wheel alignment and does not indicate the height of an actual vehicle.

(a) Bounce the vehicle up and down at the corners to stabilize the suspension.

| (b) Measure the vehicle height. Measurement Points:

Vehicle Height (Unloaded Vehicle):

|

| |||||||

3. INSPECT CAMBER, CASTER AND STEERING AXIS INCLINATION

NOTICE:

Inspect while the vehicle is unloaded.

| (a) Install a camber-caster-kingpin gauge and place the front wheels on the center of a turning radius gauge. |

|

(b) Inspect the camber, caster and steering axis inclination.

Camber (Unloaded Vehicle):

| Camber Inclination | Right-left Difference |

|---|---|

| -1°23' +/- 0°45' (-1.38° +/- 0.75°) | 0°45' (0.75°) or less |

Caster (Unloaded Vehicle):

| Caster Inclination | Right-left Difference |

|---|---|

|

*1: w/ Brake Air Duct

*2: w/o Brake Air Duct | |

| 6°04' +/- 0°45' (6.07° +/- 0.75°)*1 6°03' +/- 0°45' (6.05° +/- 0.75°)*2 | 0°45' (0.75°) or less |

Steering Axis Inclination (Unloaded Vehicle):

| Steering Axis Inclination Reference |

|---|

|

*1: w/ Brake Air Duct

*2: w/o Brake Air Duct |

| 14°34' (14.57°)*1 14°33' (14.55°)*2 |

4. ADJUST CAMBER

NOTICE:

Inspect toe-in after the camber has been adjusted.

(a) Remove the front wheel.

Click here

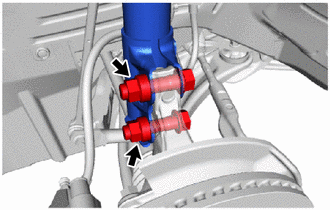

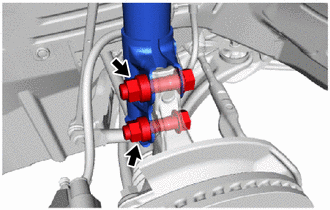

| (b) Remove the 2 nuts on the lower side of the front shock absorber. NOTICE: Keep the bolts inserted. |

|

(c) Remove the top and bottom bolts one at a time and confirm that the steering knuckle can move freely in the front shock absorber assembly.

HINT:

- Reinstall each bolt after removing it and confirming steering knuckle movement.

- If the steering knuckle does not move freely in the front shock absorber, clean the installation surfaces of the front shock absorber and the steering knuckle.

(d) Temporarily install the 2 nuts. (Step A)

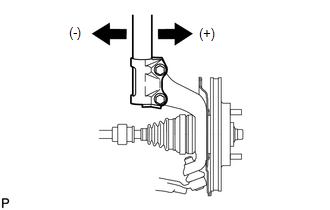

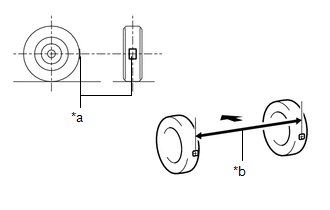

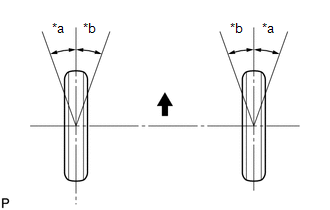

| (e) Fully push or pull the front axle hub in the direction of the required adjustment. (Step B) |

|

| (f) Tighten the 2 nuts. NOTICE: Keep the bolts from rotating when tightening the nuts. Torque: 270 N·m {2753 kgf·cm, 199 ft·lbf} |

|

(g) Install the front wheel.

Click here

(h) Bounce the vehicle up and down at the corners to stabilize the suspension.

(i) Check the camber.

Camber (Unloaded Vehicle):

| Camber Inclination | Right-left Difference |

|---|---|

| -1°23' +/- 0°45' (-1.38° +/- 0.75°) | 0°45' (0.75°) or less |

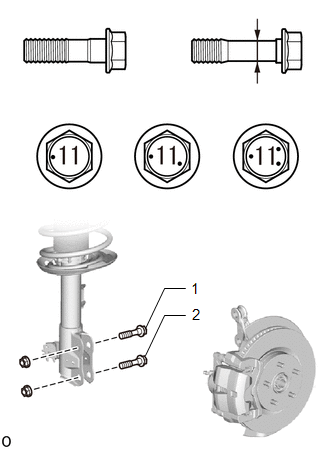

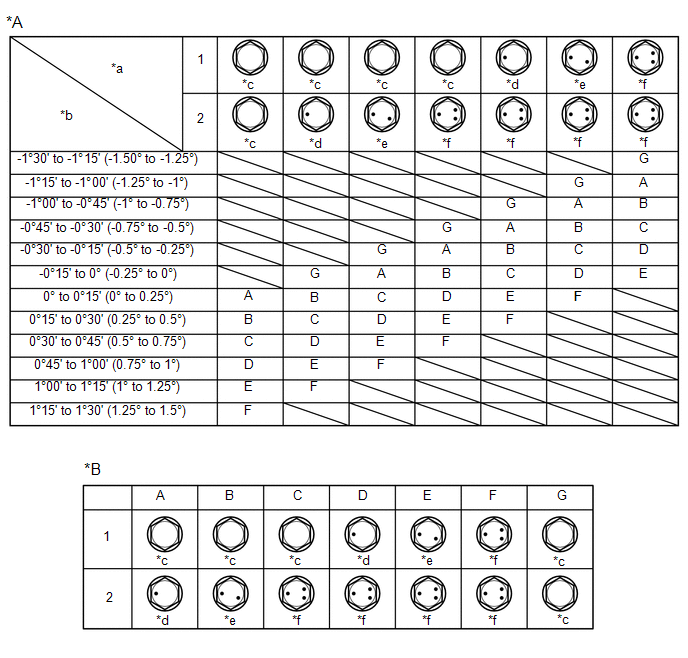

| (1) If the measured value is not within the specification, calculate the required adjustment amount using the formula below. Camber adjustment amount = center of the specified range - measured value Check the combination of the installed bolts. Select appropriate bolts from the tables below to adjust the camber to the specified values. HINT:

The vehicle body and suspension may be damaged if the camber cannot be correctly adjusted according to the table above. NOTICE: Replace the nut with a new one when replacing the bolt. |

|

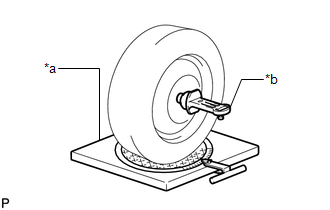

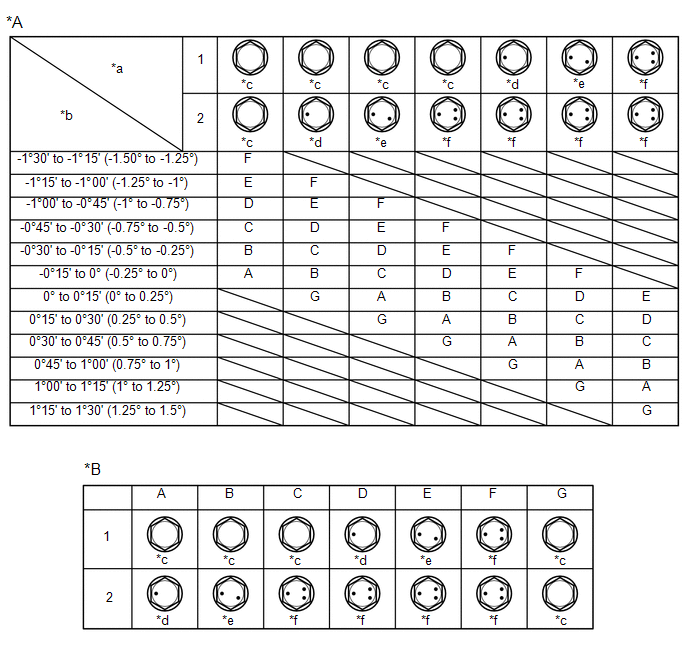

(2) Table (1) (To move the axle hub toward the positive side)

| *A | Table (1) (To move the axle hub toward the positive side) | *B | Selected Bolt Combination |

| *a | Installed Bolt | *b | Adjusting Value |

| *c | Standard Bolt | *d | 90105-17013 |

| *e | 90105-17014 | *f | 90105-17015 |

(3) Table (2) (To move the axle hub toward the negative side)

| *A | Table (2) (To move the axle hub toward the negative side) | *B | Selected Bolt Combination |

| *a | Installed Bolt | *b | Adjusting Value |

| *c | Standard Bolt | *d | 90105-17013 |

| *e | 90105-17014 | *f | 90105-17015 |

(j) If the camber was out of adjustment in the previous step, perform the adjust camber steps mentioned above. In step A, replace the existing bolts with the selected bolts.

HINT:

Replace one bolt at a time when replacing both bolts.

5. INSPECT TOE-IN

NOTICE:

Inspect while the vehicle is unloaded.

(a) Bounce the vehicle up and down at the corners to stabilize the suspension.

(b) Release the parking brake and move the shift lever to neutral.

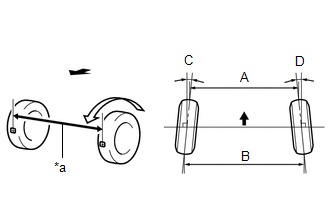

(c) Push the vehicle straight ahead approximately 5 m (16.4 ft.). (Step C)

(d) Put tread center marks on the rearmost points of the front wheels and measure the distance between the marks (dimension B).

| *a | Tread Center Mark |

| *b | Dimension B |

| Front of the Vehicle |

(e) Slowly push the vehicle straight ahead to cause the front wheels to rotate 180°. Use the front tire valve as a reference point.

HINT:

Do not allow the wheels to rotate more than 180°. If the wheels rotate more than 180°, perform the procedure from step C again.

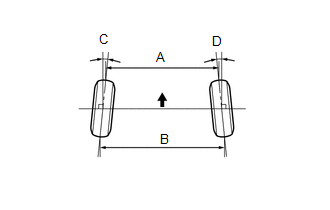

(f) Measure the distance between the tread center marks on the front of the wheels (dimension A).

| *a | Dimension A |

| Front of the Vehicle |

Toe-in (Unloaded Vehicle):

| Specified Condition |

|---|

|

*1: w/ Brake Air Duct

*2: w/o Brake Air Duct |

| C + D: 0°08' +/- 0°11' (0.14° +/- 0.18°)*1 C + D: 0°10' +/- 0°11' (0.16° +/- 0.18°)*2 |

| B - A: 1.6 +/- 2.0 mm (0.0630 +/- 0.0787 in.)*1 B - A: 1.8 +/- 2.0 mm (0.0709 +/- 0.0787 in.)*2 |

HINT:

Measure "B - A" only when "C + D" cannot be measured.

If the toe-in is not within the specified range, adjust it at the rack ends.

6. ADJUST TOE-IN

(a) Separate the steering rack boot clips from the steering rack boot.

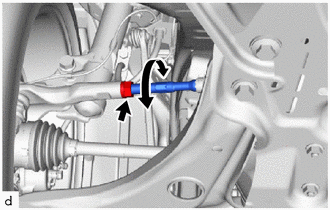

| (b) Loosen the tie rod end lock nuts. |

|

(c) Turn the right and left steering rack ends by an equal amount to adjust the toe-in.

HINT:

- If the toe-in measurement is more than the specified range, shorten the left and right steering rack ends until the measurement is within the specified range.

- If the toe-in measurement is less than the specified range, extend the left and right steering rack ends until the measurement is within the specified range.

Toe-in (Unloaded Vehicle):

| Specified Condition |

|---|

|

*1: w/ Brake Air Duct

*2: w/o Brake Air Duct |

| C + D: 0°08' +/- 0°11' (0.14° +/- 0.18°)*1 C + D: 0°10' +/- 0°11' (0.16° +/- 0.18°)*2 |

| B - A: 1.6 +/- 2.0 mm (0.0630 +/- 0.0787 in.)*1 B - A: 1.8 +/- 2.0 mm (0.0709 +/- 0.0787 in.)*2 |

HINT:

Perform adjustments so that the value is as close as possible to the median of the specified range.

| Front of the Vehicle |

(d) Tighten the tie rod end sub-assembly lock nuts.

(1) for LH side:

Click here

(2) for RH side:

HINT:

Perform the same procedure as for the LH side.

(e) Place the steering rack boots on the seats and install the steering rack boot clips.

(1) for LH side:

Click here

(2) for RH side:

HINT:

Perform the same procedure as for the LH side.

7. INSPECT WHEEL ANGLE

(a) Put tread center marks on the rearmost points of a turning radius gauge.

| *a | Inside |

| *b | Outside |

| Front of the Vehicle |

(b) Turn the steering wheel fully to the left and right and measure the turning angle.

NOTICE:

Inspect while the vehicle is unloaded.

Wheel Turning Angle (Unloaded Vehicle):

| Inside Wheel | Outside Wheel |

|---|---|

|

*1: w/ Brake Air Duct

*2: w/o Brake Air Duct | |

| 37°44' +/- 2°00' (37.73° +/- 2.00°)*1 37°46' +/- 2°00' (37.77° +/- 2.00°)*2 | 31°5' (31.08°)*1 31°6' (31.10°)*2 |

If the right and left inside wheel angles differ from the specified value, check and adjust the right and left rack end lengths.

8. ALIGN FRONT WHEELS FACING STRAIGHT AHEAD

9. INSPECT AND ADJUST HEADLIGHT AIMING

HINT:

These procedures are to be performed when suspension or tires components have been removed or replaced.

Click here

10. PERFORM CALIBRATION

Click here

11. PERFORM ECU DATA INITIALIZATION

Click here

Other information:

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Adjustment

ADJUSTMENT CAUTION / NOTICE / HINT *a Centering Bolt *b Standard Bolt HINT: Use the same procedure for the LH side and RH side. The following procedure is for the LH side. Centering bolts are used to install the door hinges to the vehicle body and door...

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Installation

INSTALLATION CAUTION / NOTICE / HINT HINT: Use the same procedure for the RH side and LH side. The following procedure is for the LH side. PROCEDURE 1. INSTALL ROOF DRIP SIDE FINISH MOULDING CLIP NOTICE: When installing a new roof drip side finish moulding clip, remove any double-sided tape remaining where the roof drip side finish moulding clips will be installed on the vehicle body and clean the vehicle body with a non-residue solvent...

Categories

- Manuals Home

- Toyota Yaris Owners Manual

- Toyota Yaris Service Manual

- To Set Speed

- Power Integration No.1 System Missing Message (B235287,B235587,B235787-B235987)

- Diagnostic Trouble Code Chart

- New on site

- Most important about car

Refueling

Before refueling, close all the doors, windows, and the liftgate/trunk lid, and switch the ignition OFF.

To open the fuel-filler lid, pull the remote fuel-filler lid release.