Toyota Yaris: Manual Transaxle System / Transmission Fluid Temperature Sensor "A" Circuit Short to Battery or Open (P071015)

DESCRIPTION

Refer to DTC P071015.

Click here

| DTC No. | Detection Item | DTC Detection Condition | Trouble Area | MIL | Memory | Note |

|---|---|---|---|---|---|---|

| P071015 | Transmission Fluid Temperature Sensor "A" Circuit Short to Battery or Open | Manual transaxle oil temperature sensor (temperature sensor) output voltage exceeds 4.9 V (circuit open or shorted) for 5 seconds or more. (1-trip detection logic |

| Does not come on | DTC stored | SAE Code: P0713 |

HINT:

When this DTC is output, check the manual transaxle oil temperature sensor (temperature sensor) in the Data List. Enter the following menus: Powertrain / Engine / Data List / M/T Oil Temperature.

| DTC No. | M/T Oil Temperature | Malfunction |

|---|---|---|

| P071015 | -40°C (-40°F) |

|

If the Data List values are normal it may be due to a temporary recovery from the malfunction condition. Check for intermittent problems.

Click here

MONITOR DESCRIPTION

The ECM calculates the temperature of the MT fluid based on the voltage output by the manual transaxle oil temperature sensor (temperature sensor). If the output voltage of the manual transaxle oil temperature sensor (temperature sensor) is outside the normal range, there may be a malfunction in the manual transaxle oil temperature sensor (temperature sensor), or an open or short in the circuit. In that case, the ECM will illuminate the MIL and store a DTC.

CONFIRMATION DRIVING PATTERN

HINT:

After repairs have been completed, clear the DTCs and then check that the vehicle has returned to normal by performing the following All Readiness check procedure.

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

- Turn the ignition switch off and wait for at least 30 seconds.

- Turn the ignition switch to ON and wait for 3 seconds or more.

- Enter the following menus: Powertrain / Engine / Utility / All Readiness.

- Input the DTC: P071015.

-

Check the DTC judgment result.

GTS Display

Description

NORMAL

- DTC judgment completed

- System normal

ABNORMAL

- DTC judgment completed

- System abnormal

INCOMPLETE

- DTC judgment not completed

- Perform driving pattern after confirming DTC enabling conditions

N/A

- Unable to perform DTC judgment

- Number of DTCs which do not fulfill DTC preconditions has reached ECU memory limit

HINT:

- If the judgment result shows NORMAL, the system is normal.

- If the judgment result shows ABNORMAL, the system has a malfunction.

- If the judgment result shows INCOMPLETE or N/A, perform the normal judgment procedure again.

WIRING DIAGRAM

Refer to DTC P071011.

Click here

PROCEDURE

| 1. | CHECK TERMINAL VOLTAGE (POWER SOURCE OF MANUAL TRANSAXLE OIL TEMPERATURE SENSOR (TEMPERATURE SENSOR)) |

(a) Disconnect the D100 manual transaxle oil temperature sensor (temperature sensor) connector.

(b) Turn the ignition switch to ON.

(c) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

| Tester Connection | Switch Condition | Specified Condition |

|---|---|---|

| D100-1 (THO) - Body ground | Ignition switch ON | 0 to 5.5 V |

(d) None.

| NG |

| GO TO STEP 3 |

|

| 2. | READ VALUE USING GTS (CHECK FOR OPEN IN WIRE HARNESS) |

(a) Disconnect the D100 manual transaxle oil temperature sensor (temperature sensor) connector.

(b) Connect terminals 1 (THO) and 2 (E2) of the manual transaxle oil temperature sensor (temperature sensor) connector on the wire harness side.

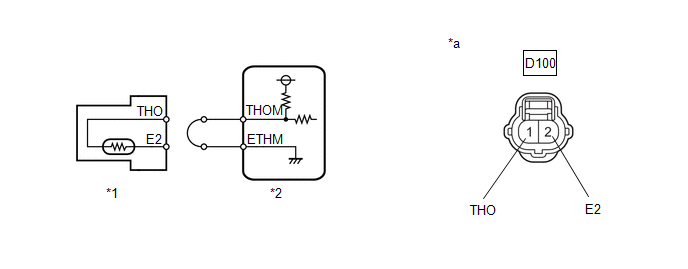

| *1 | Manual transaxle oil temperature sensor (Temperature Sensor) | *2 | ECM |

| *a | Front view of wire harness connector (to manual transaxle oil temperature sensor (Temperature Sensor)) | - | - |

(c) According to the display on the GTS, read the Data List.

Powertrain > Engine > Data List| Tester Display |

|---|

| M/T Oil Temperature |

(d) None.

| Result | Proceed to |

|---|---|

| The value of M/T Oil Temperature is higher than 135°C (275°F) | OK |

| None of the above conditions are met | NG |

| OK |

| REPLACE MANUAL TRANSAXLE OIL TEMPERATURE SENSOR (TEMPERATURE SENSOR) |

| NG |

| REPLACE ECM |

| 3. | CHECK HARNESS AND CONNECTOR (MANUAL TRANSAXLE OIL TEMPERATURE SENSOR (TEMPERATURE SENSOR) - ECM) |

(a) Disconnect the D100 manual transaxle oil temperature sensor (temperature sensor) connector.

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

| Tester Connection | Switch Condition | Specified Condition |

|---|---|---|

| D100-1 (THO) - Body ground | Ignition switch OFF | Below 1 V |

(c) None.

| NG |

| REPAIR OR REPLACE HARNESS OR CONNECTOR (MANUAL TRANSAXLE OIL TEMPERATURE SENSOR (TEMPERATURE SENSOR) - ECM) |

|

| 4. | CHECK HARNESS AND CONNECTOR (MANUAL TRANSAXLE OIL TEMPERATURE SENSOR (TEMPERATURE SENSOR) - ECM) |

(a) Disconnect the D104 ECM connector.

(b) Disconnect the D100 manual transaxle oil temperature sensor (temperature sensor) sensor connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| D100-1 (THO) - D104-104 (THOM) | Always | Below 1 Ω |

| D100-2 (E2) - D104-126 (ETHM) | Always | Below 1 Ω |

| D100-2 (E2) or D104-126 (ETHM) - Other terminals | Always | 10 kΩ or higher |

(d) Connect the D100 manual transaxle oil temperature sensor (temperature sensor) connector.

(e) Connect the D104 ECM connector.

| OK |

| REPLACE ECM |

| NG |

| REPAIR OR REPLACE HARNESS OR CONNECTOR (MANUAL TRANSAXLE OIL TEMPERATURE SENSOR (TEMPERATURE SENSOR) - ECM) |

Transmission Fluid Temperature Sensor "A" Circuit Short To Ground (P071011)

Transmission Fluid Temperature Sensor "A" Circuit Short To Ground (P071011)

DESCRIPTION The manual transaxle oil temperature sensor (temperature sensor) installed inside the manual transaxle assembly detects the temperature of the fluid in the transaxle and outputs signals to the ECM according to the fluid temperature...

Input/Turbine Speed Sensor "A" Circuit Short to Battery (P071512,P071514)

Input/Turbine Speed Sensor "A" Circuit Short to Battery (P071512,P071514)

DESCRIPTION The transmission revolution sensor is mounted on the transaxle. The ECM calculates the transaxle input shaft speed using the sensor. When the input shaft rotates, the sensor generates a pulse signal and sends the signal to the ECM...

Other information:

Toyota Yaris XP210 (2020-2025) Reapir and Service Manual: Interior Light Auto Cut Circuit

DESCRIPTION The main body ECU (multiplex network body ECU) controls operation of the DOME CUT relay in order to supply power to the interior lights. When the battery saving function operates while the interior lights are on, the main body ECU (multiplex network body ECU) opens the DOME CUT relay to turn off the lights...

Toyota Yaris XP210 (2020-2025) Reapir and Service Manual: Installation

INSTALLATION PROCEDURE 1. INSTALL HOLE PLUG (a) Install the 8 hole plugs to the rear suspension member sub-assembly. 2. INSTALL REAR SUSPENSION MEMBER HOLE COVER (a) Install the 4 rear suspension member hole covers to the rear suspension member sub-assembly...

Categories

- Manuals Home

- Toyota Yaris Owners Manual

- Toyota Yaris Service Manual

- Removal

- G16e-gts (engine Mechanical)

- Brake System Control Module "A" System Voltage System Voltage Low (C137BA2)

- New on site

- Most important about car

Front Seat Belt Pretensioners

The front seat belt pretensioners are designed to deploy in moderate or severe frontal, near frontal collisions.

In addition, the pretensioners operate when a side collision or a rollover accident is detected. The pretensioners operate differently depending on what types of air bags are equipped. For more details about the seat belt pretensioner operation, refer to the SRS Air Bag Deployment Criteria.