Toyota Yaris: Smart Key System (for Entry Function) / Terminals Of Ecu

TERMINALS OF ECU

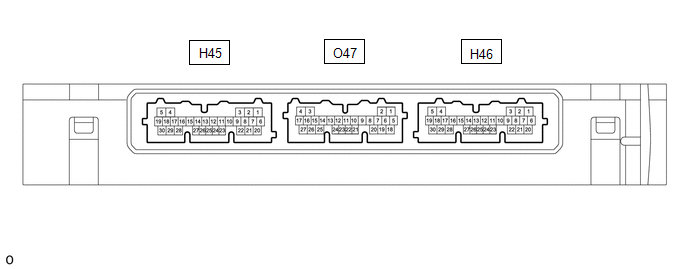

CHECK CERTIFICATION ECU (SMART KEY ECU ASSEMBLY)

(a) Disconnect the H46 certification ECU (smart key ECU assembly) connector.

(b) Measure the voltage and resistance according to the value(s) in the table below.

| Tester Connection | Terminal Description | Condition | Specified Condition | Related Data List Item |

|---|---|---|---|---|

| H46-29 (E) - Body ground | Ground | Always | Below 1 Ω | - |

| H46-6 (+B) - H46-29 (E) | Power supply | Always | 11 to 14 V | - |

| H45-22 (CUTB) - H46-29 (E) | Dark current cut pin* | Ignition switch off | 11 to 14 V | - |

- *: In order to prevent the vehicle auxiliary battery from being depleted when the vehicle is shipped long distances, a fuse that cuts unnecessary electrical load while the vehicle is being shipped is installed in the circuit. If the fuse is removed, the circuit becomes open. If the fuse that is between the vehicle auxiliary battery and terminal CUTB is removed and the circuit is open, the certification ECU (smart key ECU assembly) changes to a certain control mode (example: the transmission of radio waves every 0.25 seconds, which form the detection area, stops).

(c) Reconnect the H46 certification ECU (smart key ECU assembly) connector.

(d) Measure the voltage and check for pulses according to the value(s) in the table below.

| Tester Connection | Terminal Description | Condition | Specified Condition | Related Data List Item |

|---|---|---|---|---|

| H45-24 (IGPD) - H46-29 (E) | IG power supply | Ignition switch off → ON | Below 1 V → 9 V or higher | Power source control

|

| H45-11 (IGRD) - H46-29 (E) | IG power supply | Ignition switch off → ON | Below 1 V → 9 V or higher | Power source control

|

| H46-21 (ACCD) - H46-29 (E) | ACC power supply | Ignition switch off → ACC | Below 1 V → 8.5 V or higher | Power source control

|

| H46-16 (CLG1) - H46-29 (E) | Output to driver door electrical key antenna (request signal (challenge) is sent to door electrical key antenna from certification ECU (smart key ECU assembly) to form detection area) | Procedure:

| Pulse generation (See waveform 1) | - |

| Procedure:

| Pulse generation (See waveform 2) | - | ||

| H46-16 (CLG1) - H46-29 (E) | Input to driver door lock sensor (front door outside handle assembly LH lock sensor on signal is sent to the certification ECU (smart key ECU assembly)) | Procedure:

| Pulse generation (See waveform 3) | Smart Key

|

| H46-16 (CLG1) - H46-29 (E) | Input to driver door unlock sensor (when system is in unlock standby mode and unlock sensor is touched, door electrical key antenna sends unlock sensor input signal (sensing) to certification ECU (smart key ECU assembly)) | Procedure:

| Pulse generation (See waveform 4) | Smart Key

|

| H46-15 (CG1B) - H46-29 (E) | Output to driver door electrical key antenna (terminal on opposite side of component from CLG1 output terminal) | Procedure:

| Pulse generation (See waveform 5) | - |

| Procedure:

| Pulse generation (See waveform 6) | - | ||

| H46-10 (CLG2) - H46-29 (E) | Output to front passenger door electrical key antenna (request signal (challenge) is sent to door electrical key antenna from certification ECU (smart key ECU assembly) to form detection area) | Procedure:

| Pulse generation (See waveform 1) | - |

| Procedure:

| Pulse generation (See waveform 2) | - | ||

| H46-10 (CLG2) - H46-29 (E) | Input to front passenger door lock sensor (front door outside handle assembly LH lock sensor on signal is sent to the certification ECU (smart key ECU assembly)) | Procedure:

| Pulse generation (See waveform 3) | Smart Key

|

| H46-10 (CLG2) - H46-29 (E) | Input to front passenger door unlock sensor (when system is in unlock standby mode and unlock sensor is touched, door electrical key antenna sends unlock sensor input signal (sensing) to certification ECU (smart key ECU assembly)) | Procedure:

| Pulse generation (See waveform 4) | Smart Key

|

| H46-9 (CG2B) - H46-29 (E) | Output to front passenger door electrical key antenna (terminal on opposite side of component from CLG2 output terminal) | Procedure:

| Pulse generation (See waveform 5) | - |

| Procedure:

| Pulse generation (See waveform 6) | - | ||

| O47-4 (CLG8) - H46-29 (E) | Output to electrical key antenna (outside luggage compartment) | Procedure:

| Pulse generation (See waveform 7) | - |

| O47-3 (CG8B) - H46-29 (E) | Output to electrical key antenna (outside luggage compartment) (terminal on opposite side of component from CLG8 output terminal) | Procedure:

| Pulse generation (See waveform 8) | - |

| O47-16 (TSW5) - H46-29 (E) | Back door opener switch assembly (open switch) signal input | Back door opener switch assembly (open switch) off → on | Pulse generation (See waveform 9) | Smart Key

|

| O47-17 (TSW6) - H46-29 (E) | Back door opener switch assembly (lock switch) signal input | Back door opener switch assembly (lock switch) off → on | Pulse generation (See waveform 9) | Smart Key

|

| O47-21 (RCO) - H46-29 (E) | Output to smart door control receiver assembly (Power supply for smart door control receiver assembly. Certification ECU (smart key ECU assembly) outputs 5 V when receiver starts operating.) | Procedure:

| Pulse generation (See waveform 10) | - |

| O47-11 (RDAM) - H46-29 (E) | Smart door control receiver assembly verifies data received from electrical key transmitter sub-assembly. Smart door control receiver assembly sends data from electrical key transmitter sub-assembly to certification ECU (smart key ECU assembly) (Smart door control receiver assembly intermittently grounds 12 V signal from certification ECU (smart key ECU assembly)). | Proceed:

| Pulse generation (See waveform 11) | - |

| O47-12 (CSEL) - H46-29 (E) | Communication channel switching circuit | Procedure:

| Below 1 V → Pulse generation | - |

-

*1: For details about the entry function detection area, refer to Operation Check.

Click here

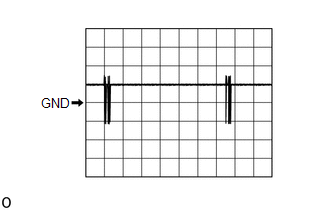

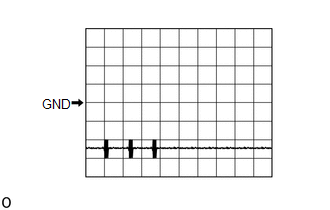

(e) Using an oscilloscope, check waveform 1.

NOTICE:

The oscilloscope waveform shown in the illustration is an example for reference only. Noise, chattering, etc. are not shown.

Waveform 1 (Reference)

Waveform 1 (Reference) | Item | Content |

|---|---|

| Tester Connection | H46-16 (CLG1) - H46-29 (E) H46-10 (CLG2) - H46-29 (E) |

| Tool Setting | 5 V/DIV., 500 ms./DIV. |

| Condition | Procedure:

|

-

*: For details about the entry function detection area, refer to Operation Check.

Click here

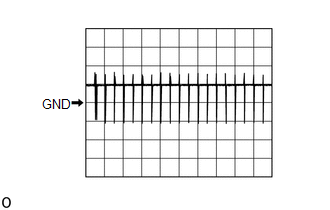

(f) Using an oscilloscope, check waveform 2.

NOTICE:

The oscilloscope waveform shown in the illustration is an example for reference only. Noise, chattering, etc. are not shown.

Waveform 2 (Reference)

Waveform 2 (Reference) | Item | Content |

|---|---|

| Tester Connection | H46-16 (CLG1) - H46-29 (E) H46-10 (CLG2) - H46-29 (E) |

| Tool Setting | 5 V/DIV., 500 ms./DIV. |

| Condition | Procedure:

|

-

*: For details about the entry function detection area, refer to Operation Check.

Click here

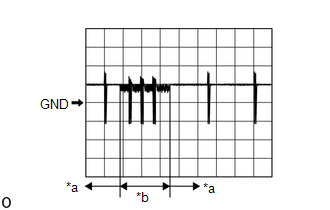

(g) Using an oscilloscope, check waveform 3.

NOTICE:

The oscilloscope waveform shown in the illustration is an example for reference only. Noise, chattering, etc. are not shown.

| *a | Lock sensor not touched |

| *b | Lock sensor touched |

| Item | Content |

|---|---|

| Tester Connection | H46-16 (CLG1) - H46-29 (E) |

| Tool Setting | 5 V/DIV., 100 ms./DIV. |

| Condition | Procedure:

|

| Item | Content |

|---|---|

| Tester Connection | H46-10 (CLG2) - H46-29 (E) |

| Tool Setting | 5 V/DIV., 100 ms./DIV. |

| Condition | Procedure:

|

-

*: For details about the entry function detection area, refer to Operation Check.

Click here

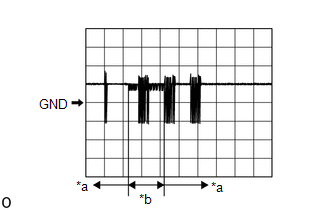

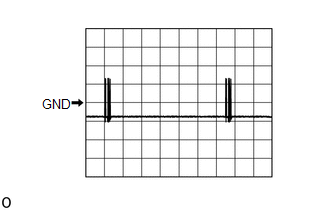

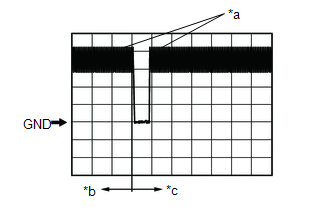

(h) Using an oscilloscope, check waveform 4.

NOTICE:

The oscilloscope waveform shown in the illustration is an example for reference only. Noise, chattering, etc. are not shown.

| *a | Unlock sensor not touched |

| *b | Unlock sensor touched |

| Item | Content |

|---|---|

| Tester Connection | H46-16 (CLG1) - H46-29 (E) |

| Tool Setting | 5 V/DIV., 100 ms./DIV. |

| Condition | Procedure:

|

| Item | Content |

|---|---|

| Tester Connection | H46-10 (CLG2) - H46-29 (E) |

| Tool Setting | 5 V/DIV., 100 ms./DIV. |

| Condition | Procedure:

|

(i) Using an oscilloscope, check waveform 5.

NOTICE:

The oscilloscope waveform shown in the illustration is an example for reference only. Noise, chattering, etc. are not shown.

Waveform 5 (Reference)

Waveform 5 (Reference) | Item | Content |

|---|---|

| Tester Connection | H46-15 (CG1B) - H46-29 (E) H46-9 (CG2B) - H46-29 (E) |

| Tool Setting | 5 V/DIV., 500 ms./DIV. |

| Condition | Procedure:

|

-

*: For details about the entry function detection area, refer to Operation Check.

Click here

(j) Using an oscilloscope, check waveform 6.

NOTICE:

The oscilloscope waveform shown in the illustration is an example for reference only. Noise, chattering, etc. are not shown.

Waveform 6 (Reference)

Waveform 6 (Reference) | Item | Content |

|---|---|

| Tester Connection | H46-15 (CG1B) - H46-29 (E) H46-9 (CG2B) - H46-29 (E) |

| Tool Setting | 5 V/DIV., 500 ms./DIV. |

| Condition | Procedure:

|

-

*: For details about the entry function detection area, refer to Operation Check.

Click here

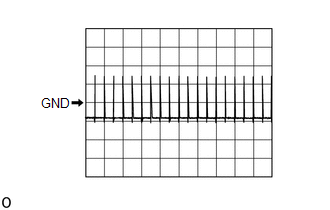

(k) Using an oscilloscope, check waveform 7.

NOTICE:

The oscilloscope waveform shown in the illustration is an example for reference only. Noise, chattering, etc. are not shown.

Waveform 7 (Reference)

Waveform 7 (Reference) | Item | Content |

|---|---|

| Tester Connection | O47-4 (CLG8) - H46-29 (E) |

| Tool Setting | 5 V/DIV., 50 ms./DIV. |

| Condition | Procedure:

|

(l) Using an oscilloscope, check waveform 8.

NOTICE:

The oscilloscope waveform shown in the illustration is an example for reference only. Noise, chattering, etc. are not shown.

Waveform 8 (Reference)

Waveform 8 (Reference) | Item | Content |

|---|---|

| Tester Connection | O47-3(CG8B) - H46-29(E) |

| Tool Setting | 5 V/DIV., 50 ms./DIV. |

| Condition | Procedure:

|

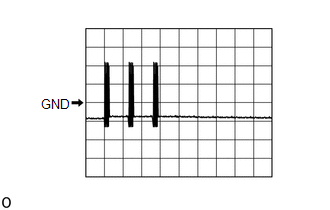

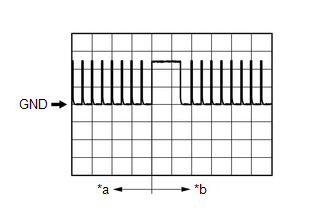

(m) Using an oscilloscope, check waveform 9.

NOTICE:

The oscilloscope waveform shown in the illustration is an example for reference only. Noise, chattering, etc. are not shown.

| *a | Checking for switch on signal at short intervals |

| *b | Before Back door opener switch assembly (open switch) pressed |

| *c | After Back door opener switch assembly (open switch) pressed |

| Item | Content |

|---|---|

| Tester Connection | O47-16 (TSW5) - H46-29 (E) |

| Tool Setting | 2 V/DIV., 500 ms./DIV. |

| Condition | Back door opener switch assembly off (open switch) → on |

| Item | Content |

|---|---|

| Tester Connection | O47-17 (TSW6) - H46-29 (E) |

| Tool Setting | 2 V/DIV., 500 ms./DIV. |

| Condition | Back door opener switch assembly (lock switch) off → on |

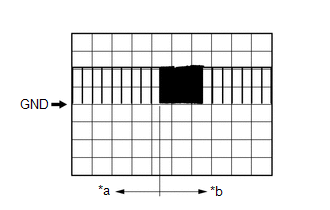

(n) Using an oscilloscope, check waveform 10.

NOTICE:

The oscilloscope waveform shown in the illustration is an example for reference only. Noise, chattering, etc. are not shown.

| *a | Before lock or unlock switch of electrical key transmitter sub-assembly pressed |

| *b | After lock or unlock switch of electrical key transmitter sub-assembly pressed |

| Item | Content |

|---|---|

| Tester Connection | O47-21 (RCO) - H46-29 (E) |

| Tool Setting | 2 V/DIV., 500 ms./DIV. |

| Condition | Procedure:

|

(o) Using an oscilloscope, check waveform 11.

NOTICE:

The oscilloscope waveform shown in the illustration is an example for reference only. Noise, chattering, etc. are not shown.

| *a | Before lock or unlock switch of electrical key transmitter sub-assembly pressed |

| *b | After lock or unlock switch of electrical key transmitter sub-assembly pressed |

| Item | Content |

|---|---|

| Tester Connection | O47-11 (RDAM) - H46-29 (E) |

| Tool Setting | 5 V/DIV., 500 ms./DIV. |

| Condition | Procedure:

|

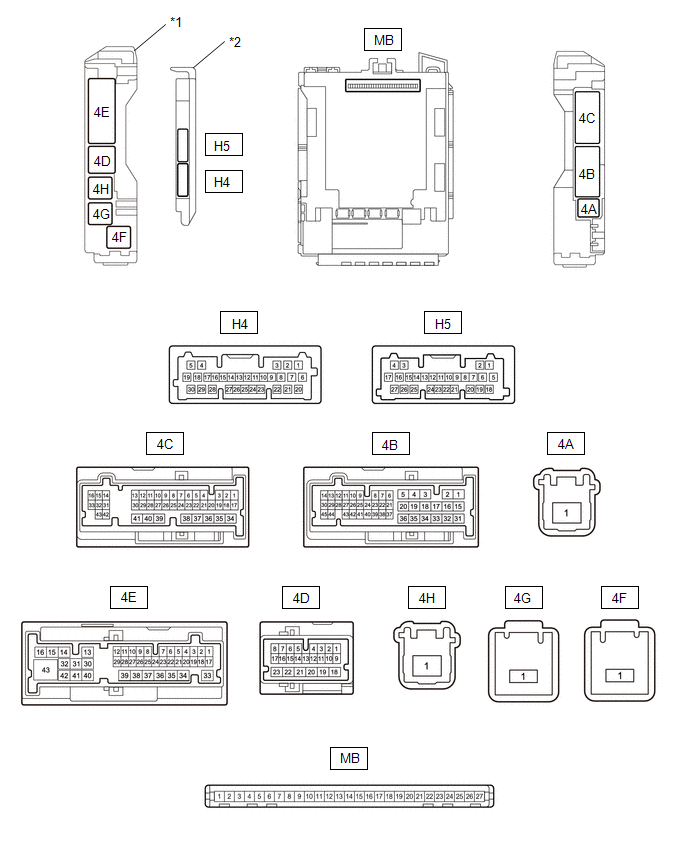

| *1 | Power Distribution Box Assembly | *2 | Main Body ECU (Multiplex Network Body ECU) |

CHECK POWER DISTRIBUTION BOX ASSEMBLY AND MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU)

(a) Remove the main body ECU (multiplex network body ECU) from the power distribution box assembly.

Click here

(b) Measure the voltage and resistance according to the value(s) in the table below.

| Tester Connection | Terminal Description | Condition | Specified Condition |

|---|---|---|---|

| MB-13 (GND1) - Body ground | Ground | Always | Below 1 Ω |

| MB-26 (BECU) - Body ground | Auxiliary battery power supply (for CPU) | Always | 11 to 14 V |

(c) Install the main body ECU (multiplex network body ECU) to the power distribution box assembly.

Click here

(d) Measure the voltage and check for pulses according to the value(s) in the table below.

| Tester Connection | Terminal Description | Condition | Specified Condition |

|---|---|---|---|

| 4D-7 (BZR) - Body ground | Wireless buzzer signal output | Procedure:

| Below 1 V → pulse generation |

SMART KEY SYSTEM (for Start Function)

Click here

POWER DOOR LOCK CONTROL SYSTEM

Click here

WIRELESS DOOR LOCK CONTROL SYSTEM

Click here

Problem Symptoms Table

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE HINT:

If a problem occurs in certain locations or at certain times of day, check for the possibility of wave interference.

When the electrical key transmitter sub-assembly is brought near a smart door control receiver assembly (RF band), door outside handle assembly (LF band), indoor electrical key antenna (LF band) or any of the electrical key antennas (LF band), the possibility of wave interference decreases...

Data List / Active Test

Data List / Active Test

DATA LIST / ACTIVE TEST NOTICE:

In the table below, the values listed under "Normal Condition" are reference values. Do not depend solely on these reference values when deciding whether a part is faulty or not...

Other information:

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Inspection

INSPECTION PROCEDURE 1. INSPECT STEERING PAD SWITCH ASSEMBLY (w/ Dynamic Radar Cruise Control System) (a) Check the resistance. (1) Measure the resistance according to the value(s) in the table below. *a Component without harness connected (Steering Pad Switch Assembly) *b Up *c Down *d Right *e Left *f OK *g Back *h On/off Hook *i Voice *j Volume+ *k Volume- *l Seek+ *m Seek- *n MODE *o +RES *p -SET *q CANCEL *r Lane Tracing Assist *s Distance Control *t Cruise Control Main Standard Resistance: Tester Connection Condition Specified Condition 3 (AU1) - 10 (EAU) No switch pushed 95 to 105 kΩ 3 (AU1) - 10 (EAU) Seek+ switch pushed Below 2...

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Removal

REMOVAL PROCEDURE 1. RECOVER REFRIGERANT FROM REFRIGERATION SYSTEM Click here 2. REMOVE HEADLIGHT ASSEMBLY LH Click here 3. REMOVE HEADLIGHT ASSEMBLY RH HINT: Use the same procedure as for the LH side. 4. REMOVE NO. 1 AIR CLEANER INLET Click here 5...

Categories

- Manuals Home

- Toyota Yaris Owners Manual

- Toyota Yaris Service Manual

- G16e-gts (engine Mechanical)

- Opening and Closing the Liftgate/Trunk Lid

- Brake System Control Module "A" System Voltage System Voltage Low (C137BA2)

- New on site

- Most important about car

Front Seat Belt Pretensioners

The front seat belt pretensioners are designed to deploy in moderate or severe frontal, near frontal collisions.

In addition, the pretensioners operate when a side collision or a rollover accident is detected. The pretensioners operate differently depending on what types of air bags are equipped. For more details about the seat belt pretensioner operation, refer to the SRS Air Bag Deployment Criteria.