Toyota Yaris: G16e-gts (engine Control) / Relay

Inspection

INSPECTION

PROCEDURE

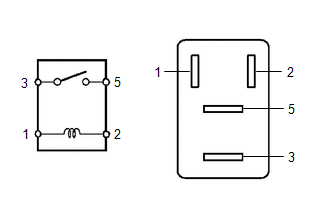

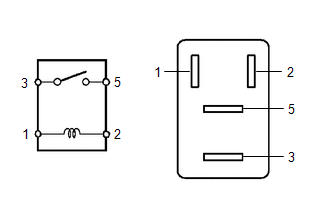

1. INSPECT NO.1 ELECTRONIC FUEL INJECTION MAIN RELAY (EFI-MAIN NO. 1)

| (a) Measure the resistance according to the value(s) in the table below. Standard Resistance:

If the result is not as specified, replace the No.1 electronic fuel injection main relay (EFI-MAIN NO. 1). |

|

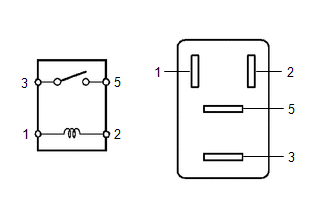

2. INSPECT NO.2 ELECTRONIC FUEL INJECTION MAIN RELAY (EFI-MAIN NO. 2)

| (a) Measure the resistance according to the value(s) in the table below. Standard Resistance:

If the result is not as specified, replace the No.2 electronic fuel injection main relay (EFI-MAIN NO. 2). |

|

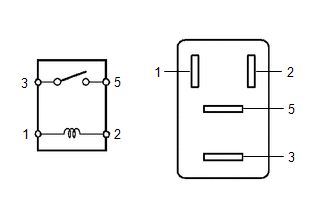

3. INSPECT NO.3 ELECTRONIC FUEL INJECTION MAIN RELAY (EFI-MAIN NO. 3)

| (a) Measure the resistance according to the value(s) in the table below. Standard Resistance:

If the result is not as specified, replace the No.3 electronic fuel injection main relay (EFI-MAIN NO. 3). |

|

4. INSPECT IGP RELAY

| (a) Measure the resistance according to the value(s) in the table below. Standard Resistance:

If the result is not as specified, replace the igp relay. |

|

Installation

Installation

INSTALLATION PROCEDURE 1. INSTALL MASS AIR FLOW METER (a) Install the mass air flow meter to the air cleaner cap sub-assembly with the 2 screws. NOTICE:

If the mass air flow meter has been struck or dropped, replace it...

Sfi System

Sfi System

..

Other information:

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Components

C..

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Fuel Pump Control Circuit Current Out of Range (P12D41D)

DESCRIPTION Refer to DTC P062712. Click here DTC No. Detection Item DTC Detection Condition Trouble Area MIL Note P12D41D Fuel Pump Control Circuit Current Out of Range When the fuel pump control ECU operation duty ratio is 3 to 65%, overcurrent in the fuel pump circuit is detected for 3 seconds or more (1 trip detection logic)...

Categories

- Manuals Home

- Toyota Yaris Owners Manual

- Toyota Yaris Service Manual

- Engine & Hybrid System

- Key Battery Replacement

- How to connect USB port/Auxiliary jack

- New on site

- Most important about car

Refueling

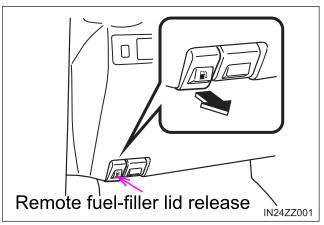

Before refueling, close all the doors, windows, and the liftgate/trunk lid, and switch the ignition OFF.

To open the fuel-filler lid, pull the remote fuel-filler lid release.