Toyota Yaris: Engine Coolant Temperature Sensor / Installation

INSTALLATION

PROCEDURE

1. INSTALL ENGINE COOLANT TEMPERATURE SENSOR

HINT:

Perform "Inspection After Repair" after replacing the engine coolant temperature sensor.

Click here

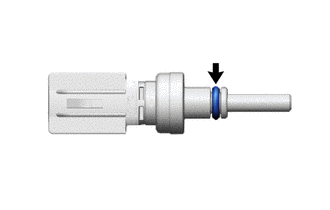

| (a) Apply a light coat of engine coolant to the O-ring of the engine coolant temperature sensor. |

|

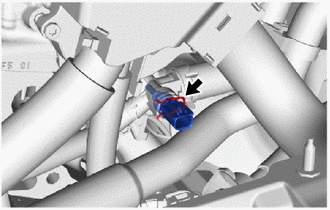

| (b) Install the engine coolant temperature sensor to the water outlet with a new clip. NOTICE:

|

|

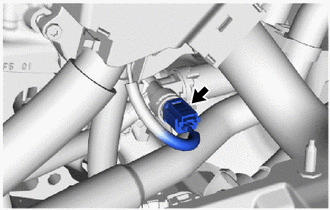

| (c) Connect the engine coolant temperature sensor connector. |

|

2. ADD ENGINE COOLANT

Click here

3. INSPECT FOR COOLANT LEAK

Click here

4. INSTALL NO. 1 ENGINE UNDER COVER ASSEMBLY

Click here

5. PERFORM INITIALIZATION

(a) Perform "Inspection After Repair" after replacing the engine coolant temperature sensor.

Click here

Removal

Removal

REMOVAL CAUTION / NOTICE / HINT The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during radiator assembly removal/installation are shown below...

Ignition Coil And Spark Plug

Ignition Coil And Spark Plug

ComponentsCOMPONENTS ILLUSTRATION

*1 SPARK PLUG *2 IGNITION COIL ASSEMBLY

N*m (kgf*cm, ft.*lbf): Specified torque - - RemovalREMOVAL CAUTION / NOTICE / HINT The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during ignition coil assembly or spark plug removal/installation are shown below...

Other information:

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Inspection

INSPECTION PROCEDURE 1. INSPECT FUEL PRESSURE SENSOR (a) Check the fuel pressure sensor output voltage. (1) Apply 5 V between terminals 1 (VC) and 2 (E2). NOTICE: Be careful when connecting the leads as the fuel pressure sensor may be damaged if the leads are connected to the wrong terminals...

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Removal

REMOVAL CAUTION / NOTICE / HINT The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during front exhaust pipe assembly and tail exhaust pipe assembly removal/installation are shown below...

Categories

- Manuals Home

- Toyota Yaris Owners Manual

- Toyota Yaris Service Manual

- Power Integration No.1 System Missing Message (B235287,B235587,B235787-B235987)

- Maintenance

- Fuel Gauge

- New on site

- Most important about car

Front Seat Belt Pretensioners

The front seat belt pretensioners are designed to deploy in moderate or severe frontal, near frontal collisions.

In addition, the pretensioners operate when a side collision or a rollover accident is detected. The pretensioners operate differently depending on what types of air bags are equipped. For more details about the seat belt pretensioner operation, refer to the SRS Air Bag Deployment Criteria.