Toyota Yaris: Front Seat Cushion Heater / Inspection

INSPECTION

PROCEDURE

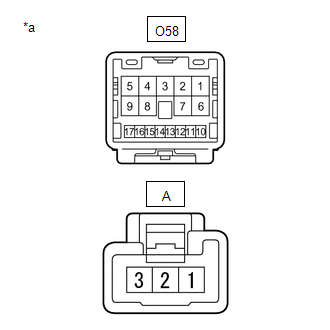

1. INSPECT FRONT SEAT CUSHION HEATER ASSEMBLY LH

| (a) Check the resistance. (1) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

| |||||||||||||||||||

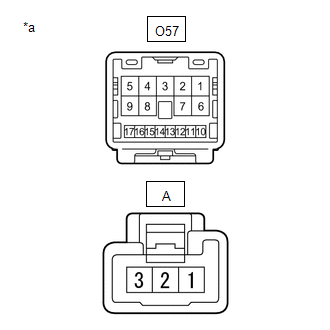

2. INSPECT FRONT SEAT CUSHION HEATER ASSEMBLY RH

| (a) Check the resistance. (1) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

| |||||||||||||||||||

Removal

Removal

REMOVAL CAUTION / NOTICE / HINT CAUTION: Wear protective gloves. Sharp areas on the parts may injure your hands.

HINT:

When the cable is disconnected / reconnected to the auxiliary battery terminal, systems temporarily stop operating...

Installation

Installation

INSTALLATION CAUTION / NOTICE / HINT CAUTION: Wear protective gloves. Sharp areas on the parts may injure your hands. HINT:

Use the same procedure for the driver side and front passenger side...

Other information:

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Back Door Courtesy Switch Circuit

DESCRIPTION The main body ECU (multiplex network body ECU) receives a back door open/closed signal from the back door courtesy light switch (back door lock assembly). WIRING DIAGRAM CAUTION / NOTICE / HINT NOTICE: Before replacing the main body ECU (multiplex network body ECU), refer to Registration...

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Right Front Wheel Speed Sensor Circuit Short to Battery (C050612)

DESCRIPTION Refer to DTC C05061F. Click here DTC No. Detection Item DTC Detection Condition Trouble Area DTC Output from C050612 Right Front Wheel Speed Sensor Circuit Short to Battery The speed sensor short signal is ON continuously for 0...

Categories

- Manuals Home

- Toyota Yaris Owners Manual

- Toyota Yaris Service Manual

- Opening and Closing the Liftgate/Trunk Lid

- Engine Start Function When Key Battery is Dead

- Maintenance

- New on site

- Most important about car

Break-In Period

No special break-in is necessary, but a few precautions in the first 600 miles (1,000 km) may add to the performance, economy, and life of the vehicle.

Do not race the engine. Do not maintain one constant speed, either slow or fast, for a long period of time. Do not drive constantly at full-throttle or high engine rpm for extended periods of time. Avoid unnecessary hard stops. Avoid full-throttle starts.