Toyota Yaris: Steering Gear / Inspection

INSPECTION

PROCEDURE

1. INSPECT TIE ROD END SUB-ASSEMBLY LH

(a) Secure the tie rod end sub-assembly LH in a vise between aluminum plates.

NOTICE:

Do not overtighten the vise.

(b) Install the nut to the stud bolt.

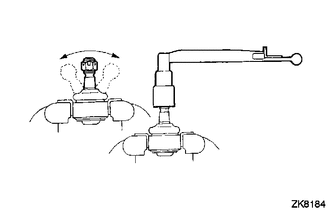

(c) Flip the ball joint back and forth 5 times.

| (d) Using a torque wrench and the nut, turn the stud bolt continuously at a rate of 2 to 4 seconds per turn, and check the turning torque on the 5th turn. Standard Turning Torque: 0.49 to 3.43 N*m (5 to 34 kgf*cm, 5 to 30 in.*lbf) HINT: If the turning torque is not within the specified range, replace the tie rod end sub-assembly LH with a new one. |

|

(e) Check that the dust cover is not cracked and that there is no grease on it.

HINT:

If the dust cover is cracked or there is grease on it, replace the tie rod end sub-assembly LH with a new one.

2. INSPECT TIE ROD END SUB-ASSEMBLY RH

HINT:

Perform the same procedure as for the LH side.

3. INSPECT TOTAL PRELOAD

NOTICE:

Inspect the total preload in a no-load condition by removing the tie rod end sub-assemblies RH and LH, and steering rack boots.

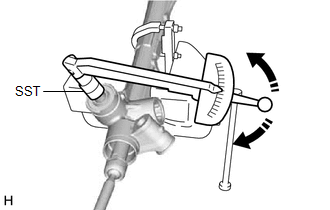

(a) Install SST to the pinion shaft and turn it left and right 5 times or more.

SST: 09616-00020

| Turn |

(b) Using SST and a torque wrench, turn the pinion shaft continuously at a rate of 4 to 6 seconds per turn to inspect the total preload of the steering gear assembly.

Standard Preload:

1.55 to 2.65 N*m (16 to 27 kgf*cm, 14 to 23 in.*lbf)

NOTICE:

Inspect the total preload around the steering rack center position.

HINT:

If the total preload is not within the specified range, replace the steering gear assembly with a new one.

Disassembly

Disassembly

DISASSEMBLY PROCEDURE 1. REMOVE STEERING RACK BOOT CLIP (for LH Side) (a) Using pliers, remove the steering rack boot clip. 2. REMOVE STEERING RACK BOOT CLIP (for RH Side) HINT: Perform the same procedure as for the LH side...

Reassembly

Reassembly

REASSEMBLY PROCEDURE 1. INSTALL NO. 2 STEERING RACK BOOT (a) Apply lithium soap base glycol grease to the inside of the small opening of a new No. 2 steering rack boot...

Other information:

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: How To Proceed With Troubleshooting

CAUTION / NOTICE / HINT HINT: Use the following procedure to troubleshoot the pre-collision system. *: Use the GTS. PROCEDURE 1. VEHICLE BROUGHT TO WORKSHOP NEXT 2. CUSTOMER PROBLEM ANALYSIS AND SYMPTOM CHECK Pre-collision System Customer Problem Analysis Vehicle Brought to Workshop Year Month Day Dealer name Person in charge at headquarters Telephone number Shop name Person in charge at shop Frame type Frame No...

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: ABS Pump Motor Actuator Stuck (C142771)

DESCRIPTION DTC No. Detection Item DTC Detection Condition Trouble Area DTC Output from C142771 ABS Pump Motor Actuator Stuck Actuator pump motor does not operate properly. Wire harness and connector Brake actuator assembly (Pump motor) Brake actuator assembly (Pump motor circuit) Brake WIRING DIAGRAM Refer to DTC C052C13...

Categories

- Manuals Home

- Toyota Yaris Owners Manual

- Toyota Yaris Service Manual

- Removal

- Auto Lock/Unlock Function

- Diagnostic Trouble Code Chart

- New on site

- Most important about car

Break-In Period

No special break-in is necessary, but a few precautions in the first 600 miles (1,000 km) may add to the performance, economy, and life of the vehicle.

Do not race the engine. Do not maintain one constant speed, either slow or fast, for a long period of time. Do not drive constantly at full-throttle or high engine rpm for extended periods of time. Avoid unnecessary hard stops. Avoid full-throttle starts.