Toyota Yaris: Sfi System / HO2S Heater Control Circuit Bank 1 Sensor 2 Circuit Short to Battery (P003612,P003613,P102A9E)

DESCRIPTION

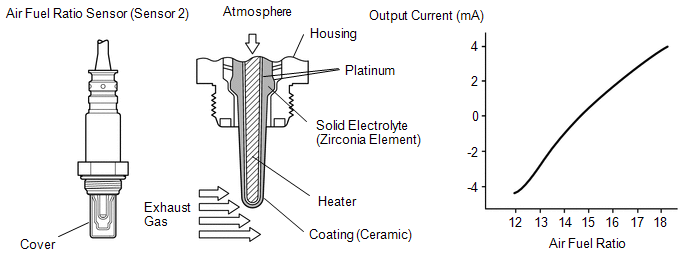

The air fuel ratio sensor (sensor 2) generates current that corresponds to the actual air fuel ratio. This sensor current is used to provide the ECM with feedback so that it can control the air fuel ratio. The ECM determines the deviation from the stoichiometric air fuel ratio level, and regulates the fuel injection duration. If the air fuel ratio sensor (sensor 2) malfunctions, the ECM is unable to control the air fuel ratio accurately.

The air fuel ratio sensor (sensor 2) is a cup type sensor and uses a zirconia element for the sensor element. The zirconium element is made of platinum coated zirconium and includes an integrated heating element. The inner surface of the zirconia element is exposed to the outside air and the outer surface of it is exposed to the exhaust gas. The zirconia element generates a voltage according to the oxygen concentration of the exhaust gas and outside air. The air fuel ratio sensor (sensor 2) becomes very efficient when heated. When the exhaust gas temperature is low, the sensor does not generate useful voltage signals without supplementary heating. Therefore, the air fuel ratio sensor (sensor 2) includes a heater to heat the zirconia element.

In order to obtain a high purification rate of the carbon monoxide (CO), hydrocarbon (HC) and nitrogen oxide (NOx) components in the exhaust gas, a three-way catalytic converter is used. For the most efficient use of the three-way catalytic converter, the air fuel ratio must be precisely controlled so that it is always close to the stoichiometric air fuel ratio.

HINT:

- When any of these DTCs are stored, the ECM enters fail-safe mode. The ECM turns off the air fuel ratio sensor (sensor 2) heater in fail-safe mode. Fail-safe mode continues until the ignition switch is turned off.

- Although the DTC titles say oxygen sensor, these DTCs relate to the air fuel ratio sensor (sensor 2).

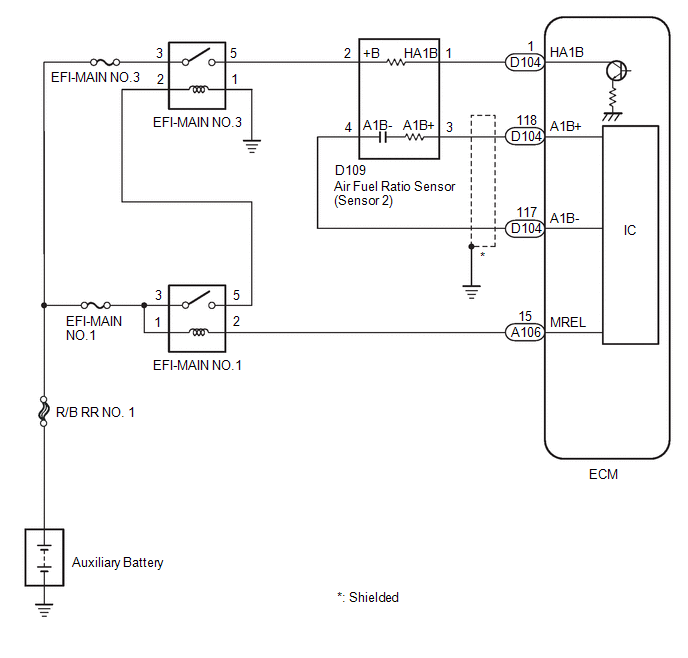

- The ECM has a pulse width modulated control circuit to adjust the current through the heater. The air fuel ratio sensor (sensor 2) heater circuit uses a relay on the +B side of the circuit.

| DTC No. | Detection Item | DTC Detection Condition | Trouble Area | MIL | Note |

|---|---|---|---|---|---|

| P003612 | HO2S Heater Control Circuit Bank 1 Sensor 2 Circuit Short to Battery | The air fuel ratio sensor (sensor 2) heater current is more than the specified value while the heater is operating (1 trip detection logic). |

| Comes on | SAE: P0038 |

| P003613 | A/F (O2) Heater Control Circuit Bank 1 Sensor 2 Circuit Open | The air fuel ratio sensor (sensor 2) heater current is less than the specified value while the heater is operating (1 trip detection logic). |

| Comes on | SAE: P0037 |

| P102A9E | O2 Sensor Heater Performance Bank 1 Sensor 2 Stuck On | The air fuel ratio sensor (sensor 2) heater voltage is the specified value or less while the heater is not operating (1 trip detection logic). |

| Comes on | SAE: P102D |

MONITOR DESCRIPTION

The air fuel ratio sensor (sensor 2) detects oxygen levels in the exhaust gas and transmits the information to the ECM. The inner surface of the sensor element is exposed to the outside air. The outer surface of the sensor element is exposed to the exhaust gas. The sensor element is made of platinum-coated zirconia and includes an integrated heating element.

The zirconia element generates a small voltage when there is a large difference in the oxygen concentrations between the exhaust gas and outside air. The platinum coating amplifies this voltage generation.

The air fuel ratio sensor (sensor 2) is more efficient when heated. When the exhaust gas temperature is low, the sensor cannot generate useful current signals without supplementary heating. The ECM regulates the supplementary heating using a duty-cycle approach to adjust the average current in the sensor heater element. If the heater current is outside the normal range, the signal transmitted by the air fuel ratio sensor (sensor 2) becomes inaccurate. As a result, the ECM is unable to regulate the air fuel ratio properly.

Air Fuel Ratio Sensor (Sensor 2) Heater Range Check (P003612 and P003613):-

The ECM monitors the current applied to the air fuel ratio sensor (sensor 2) heater to check the heater for malfunctions.

If the heater current is outside the normal range, the signal transmitted by the air fuel ratio sensor (sensor 2) becomes inaccurate. When the current in the air fuel ratio sensor (sensor 2) heater is outside the normal operating range, the ECM interprets this as a malfunction in the sensor heater and stores a DTC.

- When the air fuel ratio sensor (sensor 2) heater terminal voltage is the specified value or less while the heater is not operating, the ECM determines that there is a malfunction in the sensor heater and stores DTC.

MONITOR STRATEGY

| Frequency of Operation | Continuous |

TYPICAL ENABLING CONDITIONS

P0037| Output duty cycle | 30% or higher |

| Output duty cycle | Higher than 5% |

| Output duty cycle | Less than 95% |

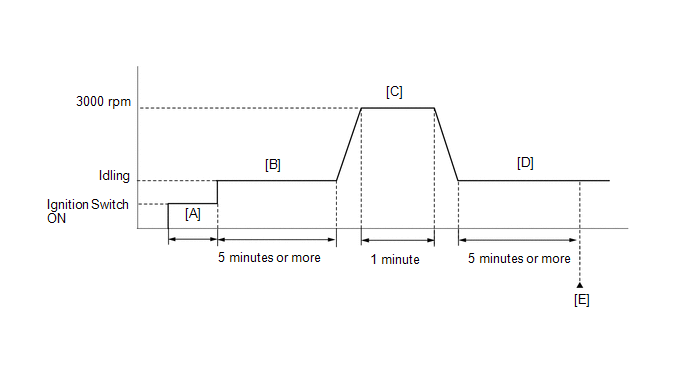

CONFIRMATION DRIVING PATTERN

- Connect the GTS to the DLC3.

- Turn the ignition switch to ON.

- Turn the GTS on.

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

- Turn the ignition switch off and wait for at least 30 seconds.

- Turn the ignition switch to ON [A].

- Turn the GTS on.

- Start the engine and idle it for 5 minutes or more [B].

- With the vehicle stationary, depress the accelerator pedal and maintain an engine speed of 3000 rpm for 1 minute [C].

- Idle the engine for 5 minutes or more [D].

- Enter the following menus: Powertrain / Engine / Trouble Codes [E].

-

Read the pending DTCs.

HINT:

- If a pending DTC is output, the system is malfunctioning.

- If a pending DTC is not output, perform the following procedure.

- Enter the following menus: Powertrain / Engine / Utility / All Readiness.

- Input the DTC: P003612, P003613 or P102A9E

-

Check the DTC judgment result.

GTS Display

Description

NORMAL

- DTC judgment completed

- System normal

ABNORMAL

- DTC judgment completed

- System abnormal

INCOMPLETE

- DTC judgment not completed

- Perform driving pattern after confirming DTC enabling conditions

HINT:

- If the judgment result is NORMAL, the system is normal.

- If the judgment result is ABNORMAL, the system has a malfunction.

- If the judgment result is INCOMPLETE, perform steps [B] through [E] again.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for circuits related to this system before performing the following procedure.

HINT:

-

Refer to "Data List / Active Test" [A/F Sensor Heater Duty B1S2].

Click here

-

Change the fuel injection volume using the Control the Injection Volume for A/F Sensor function provided in the Active Test and monitor the air fuel ratio sensor (sensor 2) output current (Click here

). If the sensor output current does not change (almost no reaction) while performing the Active Test, the sensor may be malfunctioning.

). If the sensor output current does not change (almost no reaction) while performing the Active Test, the sensor may be malfunctioning.

- Read Freeze Frame Data using the GTS. The ECM records vehicle and driving condition information as Freeze Frame Data the moment a DTC is stored. When troubleshooting, Freeze Frame Data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, if the air fuel ratio was lean or rich, and other data from the time the malfunction occurred.

- Sensor 1 refers to the sensor closest to the engine assembly.

- Sensor 2 refers to the sensor farthest away from the engine assembly.

PROCEDURE

| 1. | INSPECT AIR FUEL RATIO SENSOR (SENSOR 2) (HEATER RESISTANCE) |

Click here

HINT:

Perform "Inspection After Repair" after replacing the air fuel ratio sensor (sensor 2).

Click here

| NG |

| REPLACE AIR FUEL RATIO SENSOR (SENSOR 2) |

|

| 2. | CHECK TERMINAL VOLTAGE (POWER SOURCE OF AIR FUEL RATIO SENSOR (SENSOR 2)) |

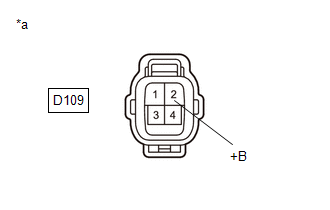

(a) Disconnect the air fuel ratio sensor (sensor 2) connector.

(b) Turn the ignition switch to ON.

| (c) Measure the voltage according to the value(s) in the table below. Standard Voltage:

|

|

| NG |

| GO TO STEP 6 |

|

| 3. | CHECK HARNESS AND CONNECTOR (AIR FUEL RATIO SENSOR (SENSOR 2) - ECM) |

(a) Disconnect the air fuel ratio sensor (sensor 2) connector.

(b) Disconnect the ECM connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| D109-1(HA1B) - D104-1(HA1B) | Always | Below 1 Ω |

| D109-1(HA1B) or D104-1(HA1B) - Body ground and other terminals | Always | 10 kΩ or higher |

| NG |

| REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 4. | CLEAR DTC |

(a) Clear the DTCs.

Powertrain > Engine > Clear DTCs(b) Turn the ignition switch off and wait for at least 30 seconds.

|

| 5. | CHECK WHETHER DTC OUTPUT RECURS (DTC P003612, P003613 OR P102A9E) |

(a) Drive the vehicle in accordance with the driving pattern described in Confirmation Driving Pattern.

(b) Read the DTCs.

Powertrain > Engine > Trouble Codes| Result | Proceed to |

|---|---|

| DTCs are not output | A |

| P003612, P003613 or P102A9E is output | B |

| A |

| CHECK FOR INTERMITTENT PROBLEMS |

| B |

| REPLACE ECM |

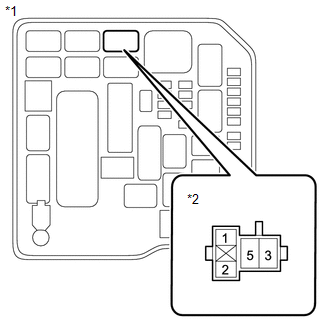

| 6. | INSPECT EFI-MAIN NO.3 RELAY |

Click here

| NG |

| REPLACE EFI-MAIN NO.3 RELAY |

|

| 7. | CHECK TERMINAL VOLTAGE (POWER SOURCE OF EFI-MAIN NO.3 RELAY) |

| (a) Remove the EFI-MAIN NO.3 relay from the No. 1 engine room relay block assembly. |

|

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| 3(EFI-MAIN NO.3 relay) - Body ground | Always | 11 to 14 V |

| NG |

| REPAIR OR REPLACE HARNESS OR CONNECTOR (AUXILIARY BATTERY - EFI-MAIN NO.3 RELAY) |

|

| 8. | CHECK HARNESS AND CONNECTOR (EFI-MAIN NO.3 RELAY - BODY GROUND) |

(a) Remove the EFI-MAIN NO.3 relay from the No. 1 engine room relay block assembly.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| 1(EFI-MAIN NO.3 relay) - Body ground | Always | Below 1 Ω |

| NG |

| REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 9. | CHECK HARNESS AND CONNECTOR (EFI-MAIN NO.3 RELAY - AIR FUEL RATIO SENSOR (SENSOR 2)) |

(a) Remove the EFI-MAIN NO.3 relay from the No. 1 engine room relay block assembly.

(b) Disconnect the air fuel ratio sensor (sensor 2) connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| 5(EFI-MAIN NO.3 relay) - D109-2(+B) | Always | Below 1 Ω |

| 5(EFI-MAIN NO.3 relay) or D109-2(+B) - Body ground and other terminals | Always | 10 kΩ or higher |

| OK |

| REPAIR OR REPLACE HARNESS OR CONNECTOR (EFI-MAIN NO. 1 RELAY - EFI-MAIN NO. 3 RELAY) |

| NG |

| REPAIR OR REPLACE HARNESS OR CONNECTOR |

Turbocharger / Supercharger Bypass Valve "A" Control Circuit Short to Ground or Open (P003314)

Turbocharger / Supercharger Bypass Valve "A" Control Circuit Short to Ground or Open (P003314)

DESCRIPTION Refer to DTC P003312. Click here

DTC No. Detection Item DTC Detection Condition Trouble Area MIL Note P003314 Turbocharger / Supercharger Bypass Valve "A" Control Circuit Short to Ground or Open Open or short in air by-pass valve assembly circuit (1 trip detection logic)...

Barometric Pressure - Turbocharger/Supercharger Inlet Pressure Correlation Bank 1 Signal Compare Failure (P006D62)

Barometric Pressure - Turbocharger/Supercharger Inlet Pressure Correlation Bank 1 Signal Compare Failure (P006D62)

DESCRIPTION The E.F.I. vacuum sensor assembly is installed upstream of the turbocharger compressor and measures the air inlet duct internal pressure with a built-in sensor...

Other information:

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Components

COMPONENTS ILLUSTRATION *1 FRONT FENDER LINER *2 FRONT SPEED SENSOR *3 FRONT FLEXIBLE HOSE - - Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping" : N*m (kgf*cm, ft.*lbf) N*m (kgf*cm, ft...

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Removal

REMOVAL CAUTION / NOTICE / HINT The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed, installed, or replaced during the engine stop and start ECU removal/installation are shown below...

Categories

- Manuals Home

- Toyota Yaris Owners Manual

- Toyota Yaris Service Manual

- Maintenance

- To Set Speed

- Key Battery Replacement

- New on site

- Most important about car

Keys

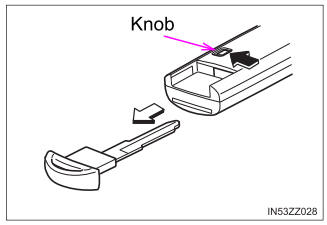

To use the auxiliary key, press the knob and pull out the auxiliary key from the smart key.