Toyota Yaris: Millimeter Wave Radar Sensor / Target Adjustment(flat Surface Target)

TARGET ADJUSTMENT(FLAT SURFACE TARGET)

PROCEDURE

1. PREPARATION FOR MILLIMETER WAVE RADAR SENSOR ASSEMBLY ADJUSTMENT

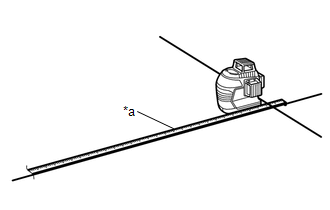

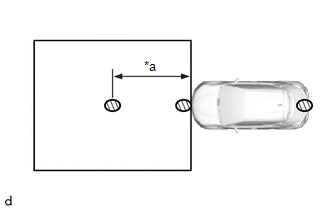

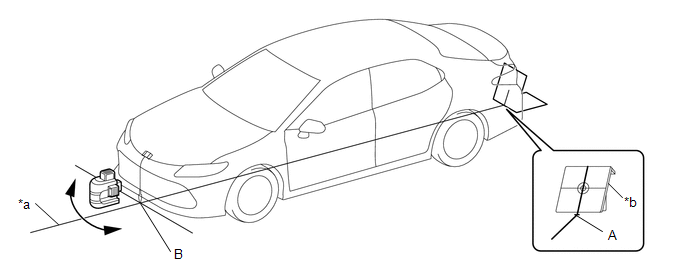

(a) Park the vehicle on a level surface where the area in front of the vehicle shown in the illustration is free of metal objects.

| *a | 2.5 m (8.2 ft.) |

| *b | 2 m (6.6 ft.) |

| Do not place any metal objects in this area |

| Do not place metal objects with a height of more than 50 mm (1.97 in.) in this area |

HINT:

Metal objects with a height of 50 mm (1.97 in.) or less placed within the area shown in the illustration will not affect the adjustment.

(b) Check the levelness of the ground.

(1) Check the levelness of the ground at the 3 points shown in the illustration.

| *a | 3 m (9.84 ft.) |

| Levelness Check Point |

(2) Place the level on each levelness check point and check that the air bubble of the level is centered.

(c) Adjust the tire inflation pressure to the specified pressure.

Click here

(d) Clean the front emblem or millimeter wave radar sensor assembly.

(e) Visually inspect the front of the vehicle.

HINT:

Confirm that there is no damage or deformation.

(f) Visually inspect the front bumper assembly, radiator grill and stays.

HINT:

Confirm that there is no damage or deformation.

2. MILLIMETER WAVE RADAR SENSOR ASSEMBLY VERTICALLY AND HORIZONTALLY

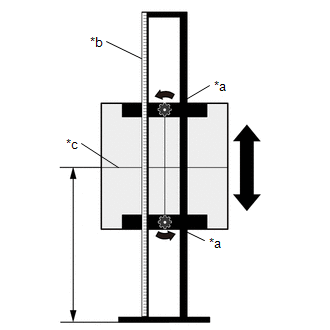

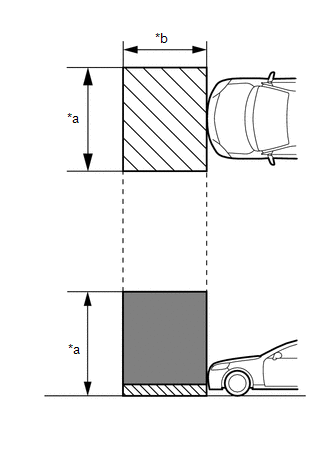

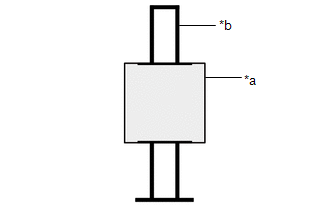

(a) Adjust SST (flat surface target) height.

| *a | SST (Flat Surface Target) |

| *b | SST (Stand) |

(1) Check that SST (flat surface target) has no damage or deformation.

SST: 09870-60100

SST: 09870-60110

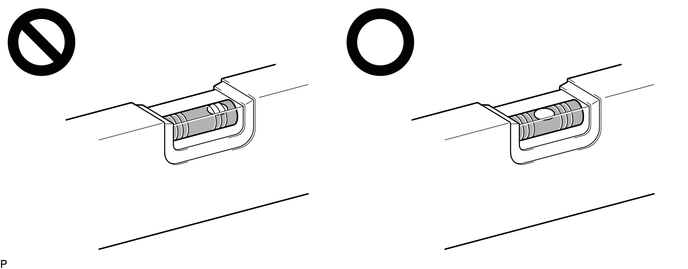

(2) Check that SST (flat surface target) is assembled correctly.

(3) Check that SST (flat surface target) has no looseness or wobble.

| (4) Loosen the top and bottom handles of SST (stand), and while checking the included scale, adjust the height of SST (flat surface target) as shown in the illustration so that its height reference line is at the same height as the millimeter wave radar sensor assembly, then re-tighten the top and bottom handles. HINT:

Reference Value: 690 mm (2.26 ft.) |

|

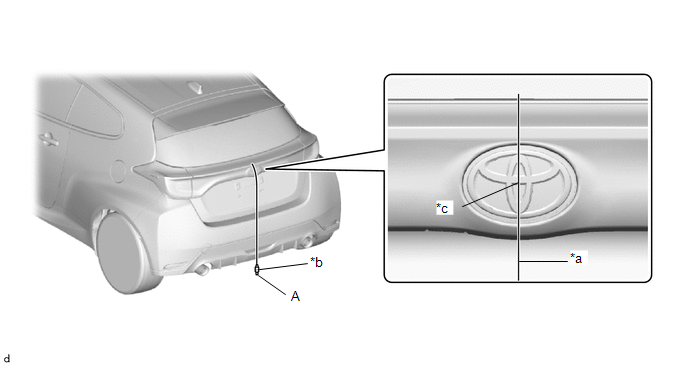

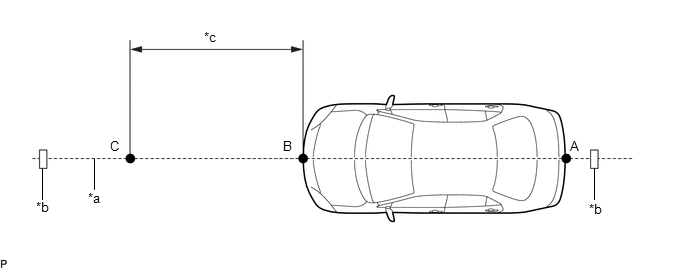

(b) Hang a weight with a pointed tip from the center of the rear emblem, and mark the rear center point of the vehicle (point A) on the ground.

| *a | String | *b | Weight |

| *c | Center | - | - |

HINT:

Lightly flick the string with your fingers several times to confirm that the string is perpendicular to the ground.

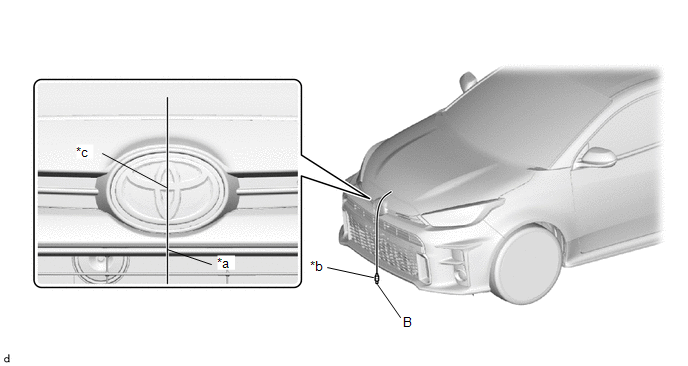

(c) Hang a weight with a pointed tip from the center of the front emblem, and mark the front center point of the vehicle (point B) on the ground.

| *a | String | *b | Weight |

| *c | Center | - | - |

HINT:

Lightly flick the string with your fingers several times to confirm that the string is perpendicular to the ground.

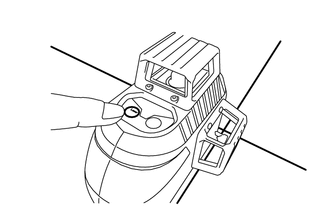

(d) When using a laser line marker:

NOTICE:

Do not look directly into the laser beam.

| (1) Press the laser mode button on the laser line marker to activate the laser line emitters. |

|

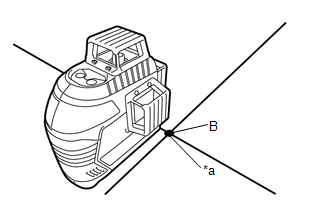

| (2) Align the laser beam ground marking point (cross portion) with point B. |

|

(3) Align the center of the target panel with point A, and set the target panel so that it faces forward.

| *a | Center Line | *b | Target Panel |

(4) Adjust the position of the laser line marker so that the laser beam is aligned with the center line of the target panel.

| (5) Extend a tape measure at least 1500 mm (4.92 ft.) in length from point B, and set the tape measure in place. |

|

| (6) Mark point C at a distance of 1500 mm (4.92 ft.) from point B, and apply a 300 mm (11.81 in.) piece of tape alongside the tape measure so that the tape extends 150 mm (5.91 in.) to the front and rear of point C. |

|

(e) When not using a laser line marker:

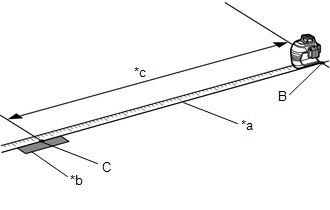

(1) Using tape and a string, create a line that connects point B to point A and extends at least 1500 mm (4.92 ft.) beyond the front center point of the vehicle.

| *a | String | *b | Tape |

| *c | 1500 mm (4.92 ft.) | - | - |

HINT:

- Make sure the string is taut when securing it with tape.

- Lightly flick the string with your fingers several times to confirm that the string is aligned with point B.

(2) Mark point C (SST (flat surface target) placement position) at a position 1500 mm (4.92 ft.) from point B.

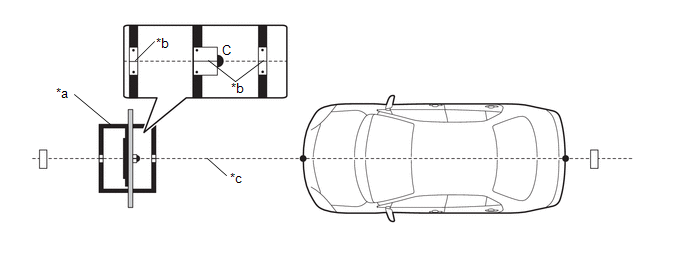

(3) Position SST (flat surface target) so that it is aligned with the target position line and the mark-off line is aligned with point C as shown in the illustration.

| *a | SST (Stand) | *b | Mark-off Line |

| *c | Reference Line | - | - |

(f) Front Beam Axis Adjustment:

NOTICE:

- Close all of the doors.

- Ensure that nobody enters the adjustment area during the adjustment.

- Do not move or shake the vehicle during adjustment (do not get in or out of the vehicle).

- Do not turn off the GTS or power switch.

- If the vehicle moves or is shaken during beam axis adjustment such as during strong winds or a door is opened or closed, perform the adjustment again.

(1) Connect the GTS to the DLC3.

(2) Turn the power switch on (IG).

(3) Turn the GTS on.

(4) Enter the following menus: Body Electrical / Front Radar Sensor / Utility / Front Beam Axis Adjustment.

Body Electrical > Front Radar Sensor > Utility| Tester Display |

|---|

| Front Beam Axis Adjustment |

(5) Press "Next".

(6) Perform the adjustment according to the display on the GTS.

NOTICE:

If an error code is displayed, perform troubleshooting according to the following table, then perform the adjustment again.

| Error No. | Error Description | Cause of Error | Action to be Taken |

|---|---|---|---|

| 1 | No target abnormality |

| Place SST (flat surface target) in the correct position. (See page 2. MILLIMETER WAVE RADAR SENSOR ASSEMBLY VERTICALLY AND HORIZONTALLY (b) Place SST (flat surface target)) |

| Clean the front emblem or millimeter wave radar sensor assembly. | |||

| Check the installation condition of the front bumper assembly and radiator grill. | |||

| Remove any reflective objects. | ||

| Ensure that nobody enters the adjustment area during the adjustment. (See page 1. PREPARATION FOR MILLIMETER WAVE RADAR SENSOR ASSEMBLY ADJUSTMENT) | |||

| Place SST (flat surface target) in the correct position. (See page 2. MILLIMETER WAVE RADAR SENSOR ASSEMBLY VERTICALLY AND HORIZONTALLY (b)Place SST (flat surface target)) | ||

| Perform adjustment in an area with no wind. | |||

| 5 | Axis adjustment |

| Optical axis adjustment. (See page 2. MILLIMETER WAVE RADAR SENSOR ASSEMBLY VERTICALLY AND HORIZONTALLY (c) Front Beam Axis Adjustment) |

| 6 | Target angle abnormality |

| Place SST (flat surface target) in the correct position. (See page 2. MILLIMETER WAVE RADAR SENSOR ASSEMBLY VERTICALLY AND HORIZONTALLY (b)Place SST (flat surface target)) |

| Check the condition of the sensor, radiator grill and front bumper assembly. | |||

| 7 | Radar abnormality |

| Replace the millimeter wave radar sensor assembly. |

| 8 | Radar dirtiness |

| Clean the front emblem or millimeter wave radar sensor assembly. |

| 9 | Temperature abnormality |

| Wait until the temperature drops to the operable range. |

| 10 | Voltage abnormality |

| Check the auxiliary battery voltage (specified condition: 10 to 16 V).

|

| 11 | External communication abnormality |

| Check the condition of the connectors and wire harness. |

| 12 | Radar axis aiming failure upward |

| Check the condition of the sensor, radiator grill and front bumper assembly. |

| Confirm road gradient. | |||

| 13 | Radar axis aiming failure downward |

| Check the condition of the sensor, radiator grill and front bumper assembly. |

| Confirm road gradient. | |||

| 14 | Vehicle speed abnormality |

| Ensure that the vehicle remains stationary. |

| 15 | Other |

| Re-do the Axis Adjustment |

| 16 | Time out |

|

|

| 17 | Target parameter abnormality |

| Perform beam axis adjustment again. |

| 18 | Vehicle information undefined |

|

|

(7) Press "Exit" to finish front beam axis adjustment.

(g) Front Beam Axis Misalignment Reading:

NOTICE:

- Close all of the doors.

- Do not move or shake the vehicle during adjustment (do not get in or out of the vehicle).

- Ensure that nobody enters the adjustment area during the adjustment.

- Do not turn off the GTS or power switch.

(1) Enter the following menus: Body Electrical / Front Radar Sensor / Utility / Front Beam Axis Misalignment Reading.

Body Electrical > Front Radar Sensor > Utility| Tester Display |

|---|

| Front Beam Axis Misalignment Reading |

(2) Press "Next".

(3) Perform the adjustment according to the display on the GTS.

Specified Condition:

| Vertical | -0.5 to 0.5 deg. |

| Horizontal | -0.5 to 0.5 deg. |

NOTICE:

If the result is not as specified, perform beam axis adjustment again.

(h) Turn the power switch off.

(i) Disconnect the GTS from the DLC3.

(j) After beam axis adjustment completes, clear the following system vehicle control history entries.

(1) Clear vehicle control history (Dynamic radar cruise control system).

Click here

(2) Clear vehicle control history (Lane Tracing Assist System).

Click here

(3) Clear vehicle control history (Front Radar Sensor system).

Click here

(4) Clear vehicle control history (Pre-collision system).

Click here

(5) Clear vehicle control history (Lighting system).

Click here

Target Adjustment(triangle Target)

Target Adjustment(triangle Target)

TARGET ADJUSTMENT(TRIANGLE TARGET) PROCEDURE 1. PREPARATION FOR MILLIMETER WAVE RADAR SENSOR ASSEMBLY ADJUSTMENT (a) Park the vehicle on a level surface where the area in front of the vehicle shown in the illustration is free of metal objects...

Other information:

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Installation

INSTALLATION CAUTION / NOTICE / HINT CAUTION: Wear protective gloves. Sharp areas on the parts may injure your hands. PROCEDURE 1. INSTALL OCCUPANT DETECTION SENSOR (SEPARATE TYPE FRONT SEAT CUSHION PAD) NOTICE: When installing a separate type front seat cushion cover, refer to Precaution in order to prevent wrinkles from forming...

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Disposal

DISPOSAL CAUTION / NOTICE / HINT CAUTION: Before performing pre-disposal deployment of any SRS part, review and closely follow all applicable environmental and hazardous material regulations. Pre-disposal deployment may be considered hazardous material treatment...

Categories

- Manuals Home

- Toyota Yaris Owners Manual

- Toyota Yaris Service Manual

- Fuel Gauge

- Diagnostic Trouble Code Chart

- G16e-gts (engine Mechanical)

- New on site

- Most important about car

Keys

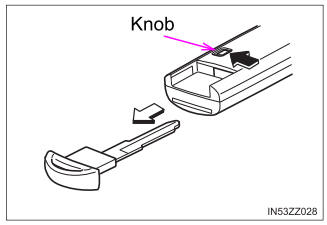

To use the auxiliary key, press the knob and pull out the auxiliary key from the smart key.