Toyota Yaris: Propeller Shaft Assembly / Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during the propeller shaft with center bearing assembly removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced| Replaced Part or Performed Procedure | Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed | Link |

|---|---|---|---|

| Gas leak from exhaust system is repaired | Inspection After Repair |

|

|

PROCEDURE

1. REMOVE FRONT EXHAUST PIPE ASSEMBLY

Click here

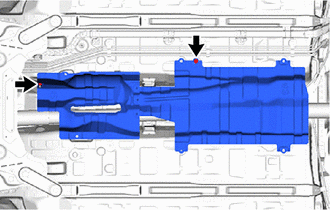

2. REMOVE FRONT FLOOR COVER LH

| (a) Remove the bolt and 3 clips. |

|

(b) Disengage the 6 clamps to remove the front floor cover LH from the vehicle body.

3. REMOVE FRONT FLOOR COVER RH

HINT:

Use the same procedure as for the LH side.

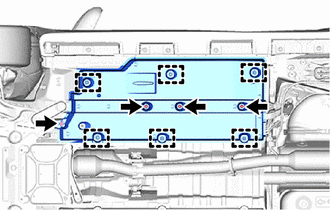

4. REMOVE FRONT NO. 1 FLOOR HEAT INSULATOR SUB-ASSEMBLY

| (a) Remove the 2 nuts and front No. 1 floor heat insulator sub-assembly from the vehicle body. |

|

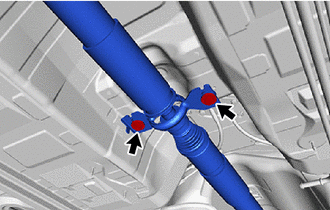

5. REMOVE PROPELLER SHAFT WITH CENTER BEARING ASSEMBLY

| (a) Remove the 2 bolts and 2 center No. 2 support bearing washers, and separate the center support bearing. |

|

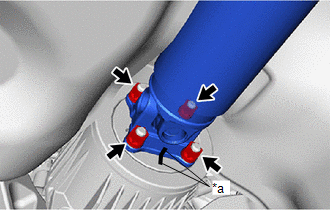

| (b) Place matchmarks on the rear differential carrier assembly and propeller shaft with center bearing assembly. |

|

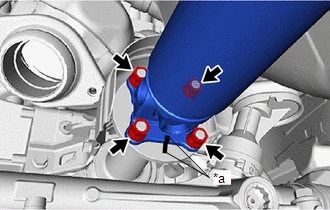

(c) Remove the 4 nuts and 4 washers, and separate the propeller shaft with center bearing assembly from the rear differential carrier assembly.

| (d) Place matchmarks on the transfer assembly and propeller shaft with center bearing assembly. |

|

(e) Remove the 4 nuts and 4 washers, and separate the propeller shaft with center bearing assembly from the transfer assembly.

Components

Components

COMPONENTS ILLUSTRATION

*1 FRONT FLOOR COVER LH *2 FRONT FLOOR COVER RH *3 FRONT NO. 1 FLOOR HEAT INSULATOR SUB-ASSEMBLY - -

N*m (kgf*cm, ft...

Inspection

Inspection

INSPECTION PROCEDURE 1. INSPECT PROPELLER SHAFT WITH CENTER BEARING ASSEMBLY (a) Using a dial indicator, measure the propeller shaft runout for the front side...

Other information:

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Actuator Supply Voltage "A" Circuit Short to Ground or Open (P065714)

DESCRIPTION The electronic throttle control system has a dedicated power supply circuit. The voltage (+BM, +BM2) is monitored and when it is low (less than 4 V), the ECM determines that there is a malfunction in the electronic throttle control system and cuts off the current to the throttle actuator...

Toyota Yaris XP210 (2020-2026) Owner's Manual: To Decrease Cruising Speed

Press the SET/- switch and hold it. The vehicle will gradually slow. Release the switch at the desired speed. Press the SET/- switch and release it immediately to adjust the preset speed. Multiple operations will decrease the preset speed according to the number of times it is operated...

Categories

- Manuals Home

- Toyota Yaris Owners Manual

- Toyota Yaris Service Manual

- Immobilizer System

- Diagnostic Trouble Code Chart

- Fuse Panel Description

- New on site

- Most important about car

Break-In Period

No special break-in is necessary, but a few precautions in the first 600 miles (1,000 km) may add to the performance, economy, and life of the vehicle.

Do not race the engine. Do not maintain one constant speed, either slow or fast, for a long period of time. Do not drive constantly at full-throttle or high engine rpm for extended periods of time. Avoid unnecessary hard stops. Avoid full-throttle starts.