Toyota Yaris: Propeller Shaft Assembly / Inspection

INSPECTION

PROCEDURE

1. INSPECT PROPELLER SHAFT WITH CENTER BEARING ASSEMBLY

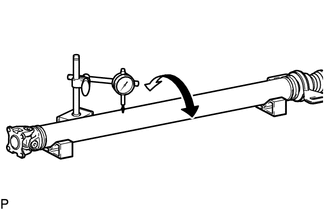

| (a) Using a dial indicator, measure the propeller shaft runout for the front side. Maximum Runout: 0.4 mm (0.0157 in.) If the runout is more than the maximum, replace the propeller shaft with center bearing assembly. NOTICE: Place the dial indicator on the center of the shaft, and perpendicular to the shaft. |

|

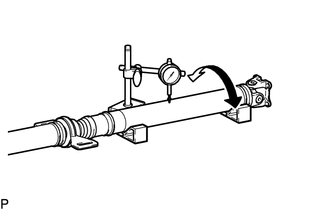

| (b) Using a dial indicator, measure the propeller shaft runout for the rear side. Maximum Runout: 0.4 mm (0.0157 in.) If the runout is more than the maximum, replace the propeller shaft with center bearing assembly. NOTICE: Place the dial indicator on the center of the shaft, and perpendicular to the shaft. |

|

Removal

Removal

REMOVAL CAUTION / NOTICE / HINT The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during the propeller shaft with center bearing assembly removal/installation are shown below...

Installation

Installation

INSTALLATION PROCEDURE 1. TEMPORARILY INSTALL PROPELLER SHAFT WITH CENTER BEARING ASSEMBLY (a) Completely remove any oil or the like and clean the contact surfaces of the transfer assembly and propeller shaft with center bearing assembly...

Other information:

Toyota Yaris XP210 (2020-2026) Owner's Manual: Warning Sound is Activated

Lights-On Reminder The lights-on reminder is operable when the time setting* 1 of the auto headlight off function is off. If lights are on and the ignition is switched to ACC or the ignition is switched off, a continuous beep sound will be heard when the driver’s door is opened...

Toyota Yaris XP210 (2020-2026) Owner's Manual: Storage Compartments

WARNING Keep storage boxes closed when driving Driving with the storage boxes open is dangerous. To reduce the possibility of injury in an accident or a sudden stop, keep the storage boxes closed when driving. Do not put articles in storage spaces with no lid Putting articles in storage spaces with no lid is dangerous as they could be thrown around the cabin if the vehicle is suddenly accelerated and cause injury depending on how the article is stored...

Categories

- Manuals Home

- Toyota Yaris Owners Manual

- Toyota Yaris Service Manual

- Headlights

- Battery Monitor Module General Electrical Failure (P058A01)

- Fuse Panel Description

- New on site

- Most important about car

Supplemental Restraint System (SRS) Precautions

The front and side supplemental restraint systems (SRS) include different types of air bags. Please verify the different types of air bags which are equipped on your vehicle by locating the “SRS AIRBAG” location indicators. These indicators are visible in the area where the air bags are installed.

The air bags are installed in the following locations:

The steering wheel hub (driver air bag) The front passenger dashboard (front passenger air bag) The outboard sides of the front seatbacks (side air bags) The front and rear window pillars, and the roof edge along both sides (curtain air bags)