Toyota Yaris: Engine / On-vehicle Inspection

ON-VEHICLE INSPECTION

CAUTION / NOTICE / HINT

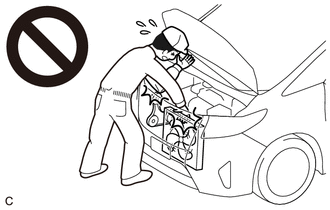

CAUTION:

-

When working near the engine room while the engine has started or the power source mode is engine switch on (IG), do not touch the fan and generator V belt or rotating components such as the fan, etc.

- Touching the fan and generator V belt or rotating components such as the fan, etc. could result in your hand or clothing getting caught and pulled in.

PROCEDURE

1. INSPECT ENGINE COOLANT

Click here

2. INSPECT ENGINE OIL

Click here

3. INSPECT AUXILIARY BATTERY CONDITION

Click here

4. INSPECT SPARK PLUG

Click here

5. INSPECT AIR CLEANER FILTER ELEMENT SUB-ASSEMBLY

(a) Remove the air cleaner filter element sub-assembly.

Click here

(b) Visually check that the air cleaner filter element sub-assembly is not damaged or excessively oily. If necessary, replace the air cleaner filter element sub-assembly.

HINT:

- If there is any dirt or clogs in the air cleaner filter element sub-assembly, clean it with compressed air.

- If any dirt or clogs remain even after cleaning the air cleaner filter element sub-assembly with compressed air, replace it.

(c) Install the air cleaner filter element sub-assembly.

Click here

6. INSPECT FAN AND GENERATOR V BELT

Click here

7. INSPECT V-RIBBED BELT TENSIONER ASSEMBLY

(a) Remove the fan and generator V belt.

Click here

(b) Turn the V-ribbed belt tensioner assembly clockwise and counterclockwise and check that it turns smoothly and does not catch.

HINT:

If the V-ribbed belt tensioner assembly does not turn smoothly or catches, replace the V-ribbed belt tensioner assembly.

(c) Install the fan and generator V belt.

Click here

8. INSPECT VALVE LASH ADJUSTER ASSEMBLY NOISE

(a) Rev up the engine several times. Check that the engine does not emit unusual noises.

(b) If unusual noises occur, warm up the engine and idle it for 30 minutes or more, then perform the inspection.

HINT:

If any defects or problems are found during the inspection, perform the valve lash adjuster assembly inspection.

Click here

9. INSPECT IGNITION TIMING

NOTICE:

- Check the ignition timing with the cooling fan off.

- Turn off all electrical systems and the A/C.

- When checking the ignition timing, the transaxle should be in neutral or park.

(a) Warm up and stop the engine.

(b) Connect the GTS to the DLC3.

(c) Start the engine and run it at idle.

(d) Turn the GTS on.

(e) Enter the following menus: Powertrain / Engine / Data List / Ignition Timing Cylinder #1.

Powertrain > Engine > Data List| Tester Display |

|---|

| Ignition Timing Cylinder #1 |

Standard Ignition Timing:

| Condition | Specified Condition |

|---|---|

| Idle speed | -5 to 15°CA BTDC |

(f) Enter the following menus: Powertrain / Engine / Active Test / Activate the TC Terminal / ON.

Powertrain > Engine > Active Test| Active Test Display |

|---|

| Activate the TC Terminal |

| Data List Display |

|---|

| Ignition Timing Cylinder #1 |

(g) Monitor Ignition Timing Cylinder #1 of the Data List.

Standard Ignition Timing:

| Condition | Specified Condition |

|---|---|

| Idle speed | 8 to 12°CA BTDC |

(h) Enter the following menus: Powertrain / Engine / Active Test / Activate the TC Terminal / OFF.

(i) Check that the ignition timing advances immediately when the engine speed is increased.

10. INSPECT ENGINE IDLE SPEED

NOTICE:

- Check the ignition timing with the cooling fan off.

- Turn off all electrical systems and the A/C.

- When checking the ignition timing, the transaxle should be in neutral or park.

(a) Warm up and stop the engine.

(b) Connect the GTS to the DLC3.

(c) Start the engine and run it at idle.

(d) Turn the GTS on.

(e) Enter the following menus: Powertrain / Engine / Data List / Engine Speed.

Powertrain > Engine > Data List| Tester Display |

|---|

| Engine Speed |

(f) Read the value displayed on the tester.

Standard Idle Speed:

| Condition | Specified Condition |

|---|---|

| N Position | 950 to 1050 rpm |

11. INSPECT COMPRESSION

NOTICE:

Keep the spark plug holes free of foreign matter when measuring the compression pressure.

(a) Warm up and stop the engine.

(b) Check for DTCs.

Click here

(c) Remove the 3 spark plugs.

Click here

(d) Disconnect the No. 5 engine wire connector.

(e) Disconnect the No. 6 engine wire connector.

(f) Check the cylinder compression pressure.

(1) Insert a compression gauge into the spark plug hole.

(2) Fully open the throttle.

(3) While cranking the engine, measure the compression pressure.

Standard Compression Pressure:

| Item | Minimum Compression Pressure | Standard Compression Pressure |

|---|---|---|

| No.1 Cylinder | 980 kPa 10.0 kgf/cm2 142 psi | 1300 kPa 13.3 kgf/cm2 189 psi |

| No.2 Cylinder | 980 kPa 10.0 kgf/cm2 142 psi | 1300 kPa 13.3 kgf/cm2 189 psi |

| No.3 Cylinder | 980 kPa 10.0 kgf/cm2 142 psi | 1300 kPa 13.3 kgf/cm2 189 psi |

| Pressure Difference between Each Cylinder | - | 200 kPa or less 2.0 kgf/cm2 or less 29 psi or less |

NOTICE:

- Always use a fully charged auxiliary battery to obtain an engine speed of 250 rpm or more.

- Inspect all cylinders in the same way.

- Measure the compression pressure as quickly as possible.

(4) If the cylinder compression pressure is low, pour a small amount of engine oil into the cylinder through the spark plug hole and inspect it again.

HINT:

- If adding oil increases the compression pressure, the piston rings and/or cylinder bore may be worn or damaged.

- If the compression pressure stays low, a valve may be stuck or seated improperly, or there may be leaks in the cylinder head gasket.

(g) Connect the No. 6 engine wire connector.

(h) Connect the No. 5 engine wire connector.

(i) Install the 3 spark plugs.

Click here

(j) Clear the DTCs.

Click here

NOTICE:

After the inspection, clear the DTCs, check for DTCs again and make sure the normal system code is output.

12. INSPECT CO/HC

HINT:

This check determines whether or not the idle CO/HC complies with regulations.

(a) Start the engine.

(b) Run the engine at 2500 rpm for approximately 180 seconds.

(c) Insert a CO/HC meter testing probe at least 40 cm (1.31 ft.) into the tailpipe during idle.

(d) Immediately check the CO/HC concentration during idle and when the engine is running at 2500 rpm.

HINT:

When performing a 2 mode (with the engine idling/running at 2500 rpm) test, the measurement procedures are determined by applicable local regulations.

If the CO/HC concentration does not comply with the regulations, perform troubleshooting in the order given below.

(1) Check for DTCs.

Click here

(2) See the following table for possible causes, then inspect the applicable parts and repair them if necessary.

| CO | HC | Problem | Cause |

|---|---|---|---|

| Normal | High | Rough idle |

|

| Low | High | Rough idle (Fluctuating HC reading) |

|

| High | High | Rough idle (Black smoke from exhaust) |

|

Engine

Engine

..

Other information:

Toyota Yaris XP210 (2020-2026) Owner's Manual: Operating Tips for Android™

Requires the Android Auto app on Google Play and an Android compatible smartphone running Android™ 5.0 Lollipop or higher. Google, Android, Android Auto and other related marks are trademarks of Google LLC. To prevent loss or damage of stored data, we recommend that you always back up your data...

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Reassembly

REASSEMBLY PROCEDURE 1. INSTALL ANTENNA CORD SUB-ASSEMBLY Click here 2. INSTALL INSTRUMENT PANEL PASSENGER WITHOUT DOOR AIRBAG ASSEMBLY Click here 3. INSTALL NO. 2 INSTRUMENT PANEL WIRE Click here 4. INSTALL INSTRUMENT CLUSTER FINISH PANEL ORNAMENT (a) Engage the guide and claws to install the instrument cluster finish panel ornament...

Categories

- Manuals Home

- Toyota Yaris Owners Manual

- Toyota Yaris Service Manual

- Fuse Panel Description

- Maintenance

- Adjustment

- New on site

- Most important about car

Fuel Gauge

The fuel gauge shows approximately how much fuel is remaining in the tank when the ignition is switched ON. We recommend keeping the tank over 1/4 full.