Toyota Yaris: G16e-gts (emission Control) / Fuel Tank Cap

Inspection

INSPECTION

PROCEDURE

1. INSPECT FUEL TANK CAP ASSEMBLY

| (a) Visually check that the fuel tank cap assembly and gasket are not deformed or damaged. If the result is not as specified, replace the fuel tank cap assembly. |

|

Emission Control System

Emission Control System

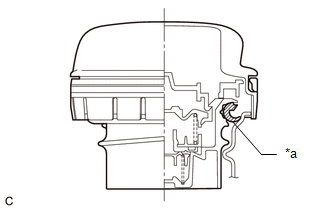

Parts LocationPARTS LOCATION ILLUSTRATION

*1 CANISTER (CHARCOAL CANISTER ASSEMBLY) *2 VACUUM REGULATING VALVE ASSEMBLY *3 FUEL TANK CAP ASSEMBLY *4 PCV VALVE (VENTILATION VALVE SUB-ASSEMBLY) *5 PURGE VALVE (PURGE VSV) *6 E...

Other information:

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Components

COMPONENTS ILLUSTRATION *1 REAR SEATBACK ASSEMBLY *2 BENCH TYPE REAR SEAT CUSHION ASSEMBLY *3 REAR SEAT CUSHION LOCK HOOK - - Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping" : N*m (kgf*cm, ft...

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Steering Lock does not Lock

DESCRIPTION The steering lock ECU (steering lock actuator or upper bracket assembly) activates the steering lock motor and moves the lock bar into the steering column to lock the steering. When the steering lock is operating, the steering may not lock when the lock bar is not aligned with the lock hole of the steering column...

Categories

- Manuals Home

- Toyota Yaris Owners Manual

- Toyota Yaris Service Manual

- How to use USB mode

- Key Battery Replacement

- Opening and Closing the Liftgate/Trunk Lid

- New on site

- Most important about car

Turning the Engine Off

Stop the vehicle completely. Manual transaxle: Shift into neutral and set the parking brake.Automatic transaxle: Shift the selector lever to the P position and set the parking brake.

Press the push button start to turn off the engine. The ignition position is off.

Copyright © 2026 www.toyaris4.com