Toyota Yaris: Gf1a (transfer / 4wd / Awd) / 4wd Control Switch

Components

COMPONENTS

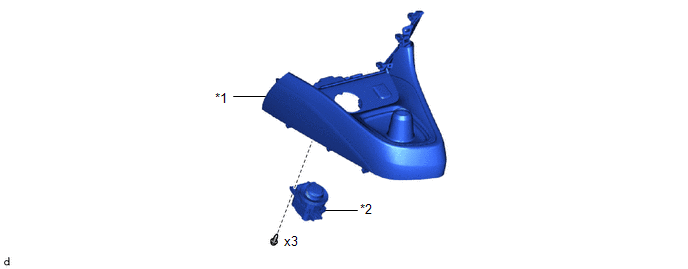

ILLUSTRATION

| *1 | CONSOLE BOX ASSEMBLY | *2 | 4WD CONTROL SWITCH (NO. 2 COMBINATION SWITCH ASSEMBLY) |

Removal

REMOVAL

PROCEDURE

1. REMOVE CONSOLE BOX ASSEMBLY

Click here

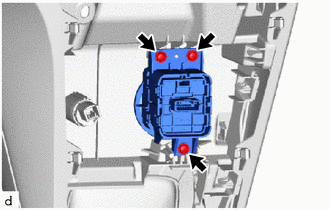

2. REMOVE 4WD CONTROL SWITCH (NO. 2 COMBINATION SWITCH ASSEMBLY)

| (a) Remove the 3 screws and 4WD control switch (No. 2 combination switch assembly). |

|

Inspection

INSPECTION

PROCEDURE

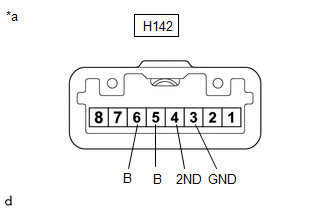

1. INSPECT 4WD CONTROL SWITCH (NO. 2 COMBINATION SWITCH ASSEMBLY)

(a) Inspect the resistance:

| (1) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

(2) If the result is not as specified, replace the 4WD control switch (No. 2 combination switch assembly).

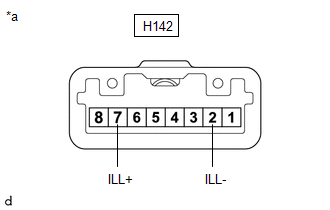

| (b) Inspect the illumination: (1) Apply battery voltage to the integration control and panel assembly (multi-terrain select switch) and check that the switch illuminates. OK:

(2) If the result is not as specified, replace the 4WD control switch (No. 2 combination switch assembly). |

|

Installation

INSTALLATION

PROCEDURE

1. INSTALL 4WD CONTROL SWITCH (NO. 2 COMBINATION SWITCH ASSEMBLY)

(a) Install the 4WD Control switch (No. 2 combination switch assembly) with the 3 screws.

2. INSTALL CONSOLE BOX ASSEMBLY

Click here

4wd Control Ecu

4wd Control Ecu

ComponentsCOMPONENTS ILLUSTRATION

*1 DECK TRIM SIDE PANEL ASSEMBLY RH *2 4WD ECU ASSEMBLY

N*m (kgf*cm, ft.*lbf): Specified torque - - RemovalREMOVAL CAUTION / NOTICE / HINT The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during the 4WD ECU removal/installation are shown below...

Other information:

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Removal

REMOVAL CAUTION / NOTICE / HINT HINT: Use the same procedure for the RH side and LH side. The following procedure is for the LH side. PROCEDURE 1. REMOVE REAR WHEEL Click here 2. REMOVE REAR AXLE SHAFT NUT (a) Using SST and a hammer, release the staked part of the rear axle shaft nut...

Toyota Yaris XP210 (2020-2026) Owner's Manual: Activation/Deactivation

To activate the system, press the ON switch. The cruise main indication (white) is displayed. To deactivate the system, press the OFF/CAN switch. The cruise main indication (white) turns off. When the ignition is switched OFF, the system status before it was turned off is maintained...

Categories

- Manuals Home

- Toyota Yaris Owners Manual

- Toyota Yaris Service Manual

- Brake System Control Module "A" System Voltage System Voltage Low (C137BA2)

- Engine & Hybrid System

- Immobilizer System

- New on site

- Most important about car

Front Seat Belt Pretensioners

The front seat belt pretensioners are designed to deploy in moderate or severe frontal, near frontal collisions.

In addition, the pretensioners operate when a side collision or a rollover accident is detected. The pretensioners operate differently depending on what types of air bags are equipped. For more details about the seat belt pretensioner operation, refer to the SRS Air Bag Deployment Criteria.