Toyota Yaris: Fuel System / Precaution

PRECAUTION

CAUTION:

-

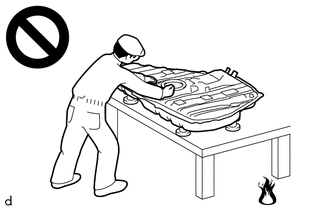

Never perform work on fuel system components near any possible ignition sources.

- Vaporized fuel could ignite, resulting in a serious accident.

-

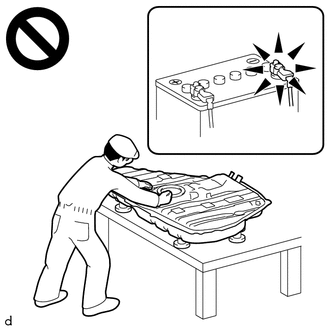

Do not perform work on fuel system components without first disconnecting the cable from the negative (-) auxiliary battery terminal.

- Sparks could cause vaporized fuel to ignite, resulting in a serious accident.

-

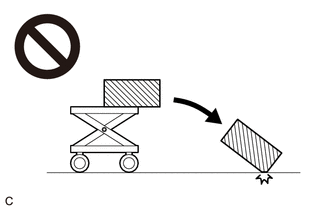

The fuel tank assembly is very heavy. Be sure to follow the procedure described in the repair manual, or the fuel tank assembly may fall off the engine lifter.

-

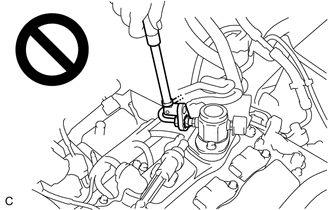

To prevent serious injury due to fuel spray from the high-pressure fuel lines, always discharge fuel system pressure before removing any fuel system components.

BEFORE WORKING ON FUEL SYSTEM

(a) Before inspecting and repairing the fuel system, disconnect the cable from the negative (-) auxiliary battery terminal.

NOTICE:

After turning the ignition switch off, waiting time may be required before disconnecting the cable from the negative (-) auxiliary battery terminal.

Click here

(b) Do not smoke or work near fire when handling the fuel system.

(c) Keep fuel away from rubber or leather parts.

DISCHARGE FUEL SYSTEM PRESSURE

CAUTION:

- Make sure the engine coolant temperature is 60°C (140°F) or less when performing this procedure.

- Perform the following procedure to prevent fuel from spraying before removing any fuel system parts.

- Pressure will still remain in the fuel lines even after performing the following procedure. When disconnecting a fuel line, cover it with a piece of cloth to prevent fuel from spraying or coming out.

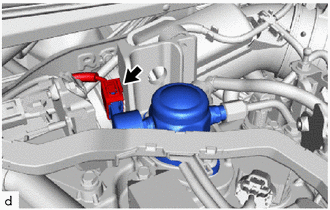

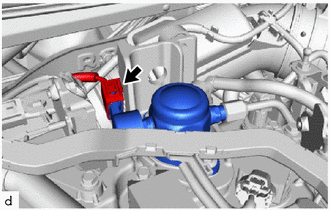

(a) When discharging fuel system pressure by disconnecting the EFI MAIN NO. 2 relay:

(1) Remove the deck board assembly

(2) Remove the deck floor box RH

(3) Remove the deck floor box LH.

(4) Remove the No.3 lower relay block cover.

(5) Remove the EFI MAIN NO. 2 relay.

(6) Start the engine and stop it after 1 minute.

(7) Disconnect the fuel pump assembly connector.

(8) Start the engine. After the engine has stopped on its own, turn the ignition switch off.

NOTICE:

Do not increase the engine speed or drive the vehicle while waiting for the engine to stop on its own.

(9) Crank the engine again and make sure that the engine does not start.

HINT:

DTC P008700 (Fuel Rail / System Pressure - Too Low) and P017100 (System Too Lean Bank 1) may be stored. Clear the DTCs before proceeding to the next step.

Click here

(10) Remove the fuel tank cap assembly and discharge the pressure from the fuel tank assembly.

(11) Disconnect the cable from the negative (-) auxiliary battery terminal.

Click here

(12) Connect the fuel pump assembly connector.

(13) Install the EFI MAIN NO. 2 relay.

(14) Install the No.3 lower relay block cover.

(15) Install the deck floor box LH.

(16) Install the deck floor box RH.

(17) Install the deck board assembly.

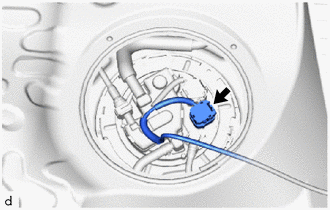

(b) When discharging fuel system pressure by disconnecting the fuel pump connector:

(1) Remove the bench type rear seat cushion assembly.

Click here

(2) Remove the rear floor service hole cover.

Click here

(3) Disconnect the fuel suction tube with pump and gauge assembly connector.

(4) Start the engine and stop it after 1 minute.

(5) Disconnect the fuel pump assembly connector.

(6) Start the engine. After the engine has stopped on its own, turn the ignition switch off.

NOTICE:

Do not increase the engine speed or drive the vehicle while waiting for the engine to stop on its own.

(7) Crank the engine again and make sure that the engine does not start.

HINT:

DTC P008700 (Fuel Rail / System Pressure - Too Low) and P017100 (System Too Lean Bank 1) may be stored. Clear the DTCs before proceeding to the next step.

Click here

(8) Remove the fuel tank cap assembly and discharge the pressure from the fuel tank sub-assembly.

(9) Disconnect the cable from the negative (-) auxiliary battery terminal.

Click here

(10) Connect the fuel suction tube with pump and gauge assembly connector.

(11) Connect the fuel pump assembly connector.

(12) Install the rear floor service hole cover.

Click here

(13) Install the bench type rear seat cushion assembly.

Click here

FUEL LINE

(a) When disconnecting a high-pressure fuel line, a large amount of fuel will spray. Perform the following procedure:

(1) Discharge fuel system pressure.

(2) Disconnect the fuel tube.

(3) Drain the fuel remaining inside the fuel tube into a container.

(4) Cover the disconnected fuel pipe and fuel tube connector with plastic bags to prevent damage and contamination.

(b) Quick Type A:

Perform the following procedure when disconnecting a fuel tube connector.

NOTICE:

Remove any dirt or foreign matter on the fuel tube connector and fuel pipe before performing this work.

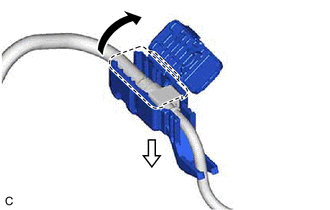

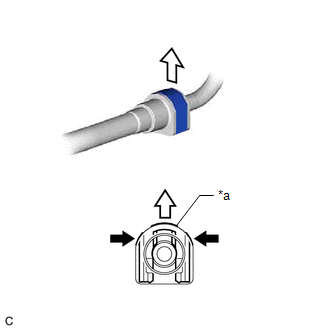

(1) Clamp Type A (No. 1 Fuel Pipe Clamp):

| Open |

| Pull |

Open the cover of the fuel pipe clamp and remove the fuel pipe clamp from the fuel tube connector.

(2) Check that there is no dirt or other foreign matter around the fuel tube connector before disconnecting it. Clean the joint if necessary.

(3) While holding the retainer at the positions shown in the illustration, pull up the retainer to disengage the lock claws.

NOTICE:

Be sure to disconnect the fuel tube connector by hand.

| *a | Retainer |

| Retainer Holding Position |

| Pull out |

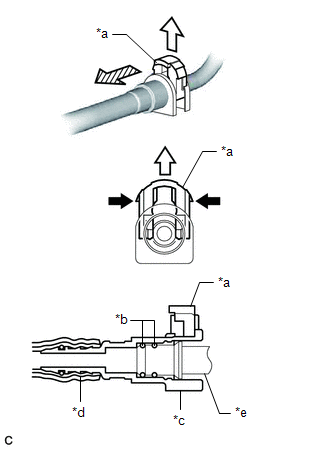

(4) Pull up the retainer while holding it at the positions shown in the illustration and pull off the fuel tube connector.

| *a | Retainer |

| *b | O-ring |

| *c | Fuel Tube Connector |

| *d | Nylon Tube |

| *e | Fuel Pipe |

| Retainer Holding Position |

| Pull out |

| Pull off |

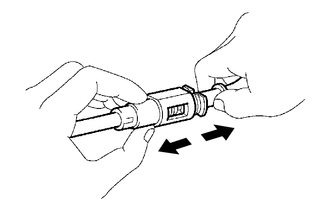

(5) If the fuel tube connector and fuel pipe are stuck, push and pull the fuel tube connector to release it. Pull the fuel tube connector off of the fuel pipe carefully.

NOTICE:

- Do not scratch or allow any foreign matter to get on the parts when disconnecting them as the fuel tube connector has O-rings that seal the pipe (fuel pipe).

- Do not bend, twist, pinch or kink the nylon tube.

(6) Check that there is no foreign matter on the sealing surfaces of the disconnected fuel lines. Clean them if necessary.

(7) Cover the disconnected fuel pipe and fuel tube connector with plastic bags to prevent damage and contamination.

(c) Quick Type A:

Perform the following procedure when connecting a fuel tube connector.

NOTICE:

Check that there is no damage or foreign matter on the connecting parts of the fuel lines.

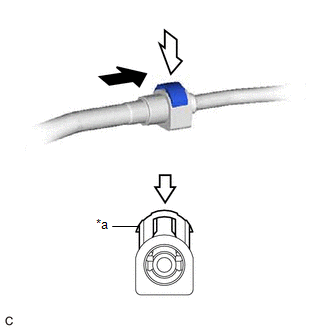

(1) Align the fuel tube connector with the fuel pipe, push the fuel tube connector onto the fuel pipe, then push in the retainer to secure the connection.

NOTICE:

Confirm that the retainer makes a "click" sound when pushed.

HINT:

If it is difficult to push the fuel tube connector onto the fuel pipe, apply a small amount of clean gasoline to the tip of the fuel pipe.

| *a | Retainer |

| Push |

| Push in |

(2) After connecting the fuel lines, check that the fuel pipe and fuel tube connector are securely connected by pulling on them.

(3) Clamp Type A (No. 1 Fuel Pipe Clamp):

Install the EFI fuel pipe clamp to the fuel tube connector and close the cover of the EFI fuel pipe clamp.

(4) Inspect for fuel leaks.

Click here

(d) Quick Type B:

Perform the following procedure when disconnecting a fuel tube connector.

NOTICE:

Remove any foreign matter on the fuel tube connector and fuel pipe before performing this work.

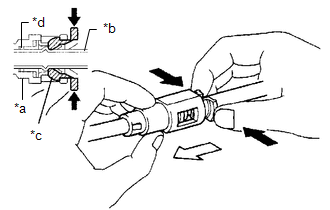

(1) Pinch the retainer of the fuel tube connector, and then pull the fuel tube connector off of the fuel pipe.

| *a | Fuel Tube Connector |

| *b | Fuel Pipe |

| *c | Retainer |

| *d | O-ring |

| Pinch |

| Pull |

NOTICE:

Be sure to disconnect the fuel tube connector by hand.

(2) If the fuel tube connector and fuel pipe are stuck, push and pull the fuel tube connector to release it. Pull the fuel tube connector off of the fuel pipe carefully.

NOTICE:

- Be sure to disconnect the fuel tube connector by hand.

- Do not scratch or allow any foreign matter to get on the parts when disconnecting them as the fuel tube connector has an O-ring that seals the pipe (fuel pipe).

(3) Check that there is no foreign matter on the sealing surfaces of the disconnected fuel lines. Clean them if necessary.

(4) Cover the disconnected fuel pipe and fuel tube connector with plastic bags to prevent damage and contamination.

(e) Quick Type B:

Perform the following procedure when connecting a fuel tube connector.

NOTICE:

Check that there is no damage or foreign matter on the connecting parts of the fuel lines.

(1) Align the fuel tube connector with the fuel pipe, and push them together until the fuel tube connector makes a "click" sound. If it is difficult to push the fuel pipe into the fuel tube connector, apply a small amount of clean gasoline to the tip of the fuel pipe and reinsert it.

| Pull |

(2) After connecting the fuel lines, check that the fuel pipe and fuel tube connector are securely connected by pulling on them.

(3) Inspect for fuel leaks.

Click here

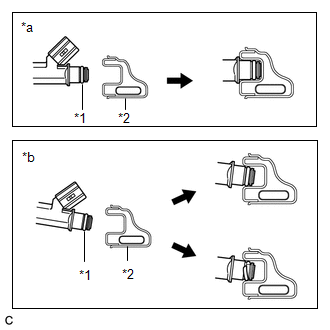

(f) Quick Type C:

Perform the following procedure when disconnecting a fuel tube connector.

NOTICE:

Check that there is no damage or foreign matter on the connecting parts of the fuel lines.

(1) Check if there is any foreign matter on the fuel pipe around the fuel tube connector before disconnecting it. Clean it if necessary.

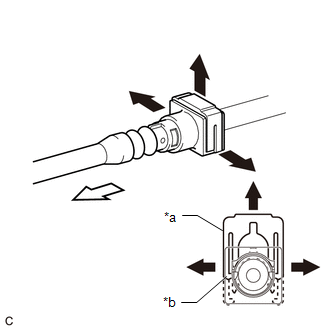

(2) Pull the retainer to disengage the 2 claws and then pull the retainer up as shown in the illustration.

| *a | Retainer |

| *b | Claw |

| Pull |

| Pull |

NOTICE:

Be sure to disconnect the fuel tube connector by hand.

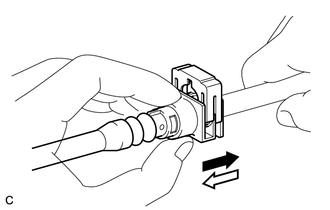

(3) If the fuel tube connector and the fuel pipe are stuck, push and pull the fuel tube connector to release it. Pull the fuel tube connector off of the fuel pipe carefully.

| Push |

| Pull |

NOTICE:

Be sure to disconnect the fuel tube connector by hand.

(4) Check if there is any foreign matter on the sealing surfaces of the disconnected fuel lines. Clean them if necessary.

(5) Cover the disconnected fuel pipe and fuel tube connector with plastic bags to prevent damage and contamination.

(g) Quick Type C:

Perform the following procedure when connecting a fuel tube connector.

NOTICE:

Check that there is no damage or foreign matter on the connecting parts of the fuel lines.

(1) Check if there is any damage or foreign matter on the connecting parts of the fuel pipes.

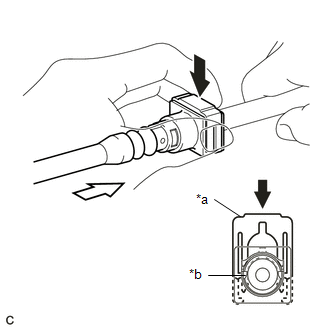

(2) Align the fuel tube connector with the fuel pipe, and them together until they are fully seated. Next, push the retainer into the fuel tube connector until its claws lock. If the fuel pipe is difficult to push into the fuel tube connector, apply a small amount of clean engine oil to the tip of the fuel pipe and reinsert it.

| *a | Retainer |

| *b | Claw |

| Push |

| Push In |

(3) After connecting the fuel lines, check that the fuel pipe and fuel tube connector are securely connected by pulling on them.

(4) Inspect for fuel leaks.

Click here

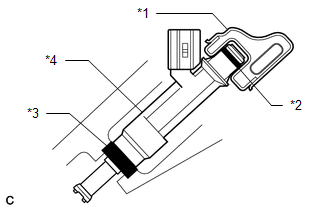

FUEL INJECTOR ASSEMBLY

(a) Observe the following precautions when removing and installing the fuel injector assemblies:

| *1 | O-ring |

| *2 | Fuel Delivery Pipe Sub-assembly |

| *a | Correct |

| *b | Incorrect |

(1) Do not reuse the O-ring or injector vibration insulator.

(2) When placing a new O-ring onto the fuel injector assembly, do not damage the O-ring.

(3) Coat a new O-ring with gasoline or spindle oil before installing it.

NOTICE:

Do not use engine oil, gear oil or brake fluid.

(b) Install the fuel injector assembly into the fuel delivery pipe sub-assembly and cylinder head sub-assembly as shown in the illustration.

| *1 | Fuel Delivery Pipe Sub-assembly |

| *2 | O-ring |

| *3 | Injector Vibration Insulator |

| *4 | Fuel Injector Assembly |

NOTICE:

Apply gasoline or spindle oil to the contact surfaces of the fuel delivery pipe sub-assembly and fuel injector assembly before installing it.

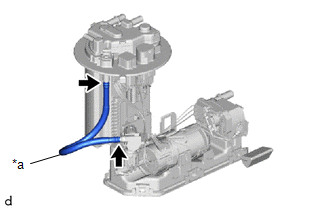

FUEL SUCTION TUBE WITH PUMP AND GAUGE ASSEMBLY

NOTICE:

-

Do not disconnect the tube shown in the illustration when disassembling the fuel suction tube with pump and gauge assembly. Doing so will cause reassembly of the fuel suction tube with pump and gauge assembly to be impossible as the tube is pressed into the fuel suction plate sub-assembly.

*a

Tube

- When replacing the fuel filter, replace it together with the fuel suction plate sub-assembly.

INSPECT FOR FUEL LEAK

(a) Check that there are no fuel leaks from the fuel system after doing any maintenance or repairs.

Click here

Fuel System

Fuel System

..

Parts Location

Parts Location

PARTS LOCATION ILLUSTRATION

*1 FUEL PUMP *2 FUEL SENDER GAUGE ASSEMBLY *3 NO. 2 FUEL SENDER GAUGE ASSEMBLY *4 FUEL PUMP CONTROL ECU *5 FUEL TANK ASSEMBLY *6 FUEL TANK VENT TUBE WITH SENDER GAUGE ASSEMBLY *7 FUEL SUCTION TUBE WITH PUMP AND GAUGE ASSEMBLY *8 FUEL MAIN VALVE ASSEMBLY *9 NO...

Other information:

Toyota Yaris XP210 (2020-2026) Owner's Manual: Fuel-Filler Cap

OpenTo remove the fuel-filler cap, turn it counterclockwise. Attach the removed cap to the inner side of the fuel lid. CloseTo close the fuel-filler cap, turn it clockwise until a click is heard. NOTICE If the check fuel cap warning light illuminates, the fuel-filler cap may not be properly installed...

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Components

COMPONENTS ILLUSTRATION *1 NO. 1 ENGINE UNDER COVER ASSEMBLY *2 CENTER NO. 4 ENGINE UNDER COVER *3 ENGINE UNDER COVER LH *4 ENGINE UNDER COVER RH N*m (kgf*cm, ft.*lbf): Specified torque - - ILLUSTRATION *1 FRONT FENDER LINER LH *2 FRONT FENDER LINER RH ILLUSTRATION *1 NO...

Categories

- Manuals Home

- Toyota Yaris Owners Manual

- Toyota Yaris Service Manual

- Maintenance

- Immobilizer System

- Diagnostic Trouble Code Chart

- New on site

- Most important about car

Turning the Engine Off

Stop the vehicle completely. Manual transaxle: Shift into neutral and set the parking brake.Automatic transaxle: Shift the selector lever to the P position and set the parking brake.

Press the push button start to turn off the engine. The ignition position is off.