Toyota Yaris: How To Troubleshoot Ecu Controlled Systems / General Information

GENERAL INFORMATION

- A large number of ECU controlled systems are used in this vehicle. In general, ECU controlled systems are considered to be very intricate, requiring a high level of technical knowledge to troubleshoot. However, most problem checking procedures only involve inspecting the ECU controlled system circuits one by one. An adequate understanding of the system and a basic knowledge of electricity is enough to perform effective troubleshooting, accurate diagnosis and necessary repairs.

-

When using the GTS

- Before using the GTS, read the operator's manual thoroughly.

-

If the GTS cannot communicate with the ECU controlled systems when connected to the DLC3 with the ignition switch ON and the GTS on, there is a problem on the vehicle side or the GTS side.

- If communication is possible when the GTS is connected to another vehicle, inspect the diagnosis data link line (bus (+) line), CANH and CANL lines, and the power source circuits of the vehicle ECUs.

- If communication is still not possible when the GTS is connected to another vehicle, the problem is probably in the GTS itself. Perform the Self Test procedure outlined in the GTS operator's manual.

TROUBLESHOOTING PROCEDURES

-

The troubleshooting procedures consist of diagnostic procedures for when a DTC is stored and diagnostic procedures for when no DTCs are stored. The basic idea is explained in the following table.

Procedure Type

Details

Troubleshooting Method

DTC Based Diagnosis

The diagnostic procedure is based on the DTC that is stored.

The malfunctioning part is identified based on the DTC detection conditions using a process of elimination.

The possible trouble areas are eliminated one-by-one using the GTS and inspection of related parts.

Symptom Based Diagnosis

(No DTCs stored)

The diagnostic procedure is based on problem symptoms.

The malfunctioning part is identified based on the problem symptoms using a process of elimination.

The possible trouble areas are eliminated one-by-one using the GTS and inspection of related parts.

- Vehicle systems are complex and use many ECUs that are difficult to inspect independently. Therefore, a process of elimination is used, where components that can be inspected individually are inspected, and if no problems are found in these components, the related ECU is identified as the problem and replaced.

- It is extremely important to ask the customer about the environment and the conditions present when the problem occurred (Customer Problem Analysis). This makes it possible to simulate the conditions and confirm the symptom. If the symptom cannot be confirmed or the DTC does not recur, the malfunctioning part may not be identified using the troubleshooting procedure, and the ECU for the related system may be replaced even though it is not defective. If this happens, the original problem will not be solved.

- In order to prevent endless expansion of troubleshooting procedures, the troubleshooting procedures are written with the assumption that multiple malfunctions do not occur simultaneously for a single problem symptom.

- To identify the malfunctioning part, troubleshooting procedures narrow down the target by separating components, ECUs and wire harnesses during the inspection. If the wire harness is identified as the cause of the problem, it is necessary to inspect not only the connections to components and ECUs but also all of the wire harness connectors between the component and the ECU.

DESCRIPTION

(a) The data of each system and Diagnostic Trouble Codes (DTCs) can be read from the Data Link Connector 3 (DLC3) of the vehicle. When the system seems to be malfunctioning, use the GTS to check for malfunctions and perform repairs.

CHECK DLC3

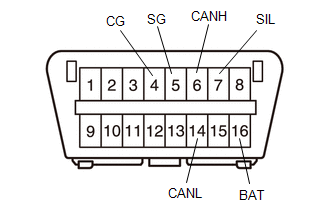

(a) The vehicle ECUs use ISO 15765-4 communication protocol. The terminal arrangement of the DLC3 complies with SAE J1962 and matches the ISO 15765-4 format.

| Terminal No. (Symbol) | Terminal Description | Condition | Specified Condition |

|---|---|---|---|

| 7 (SIL) - 5 (SG) | Bus "+" line | During transmission | Pulse generation |

| 4 (CG) - Body ground | Chassis ground | Always | Below 1 Ω |

| 5 (SG) - Body ground | Signal ground | Always | Below 1 Ω |

| 16 (BAT) - Body ground | Auxiliary battery positive | Always | 11 to 14 V |

| 6 (CANH) - 14 (CANL) | CAN bus line | Ignition switch off* | 54 to 69 Ω |

| 6 (CANH) - 4 (CG) | HIGH-level CAN bus line | Ignition switch off* | 200 Ω or higher |

| 14 (CANL) - 4 (CG) | LOW-level CAN bus line | Ignition switch off* | 200 Ω or higher |

| 6 (CANH) - 16 (BAT) | HIGH-level CAN bus line | Ignition switch off* | 6 kΩ or higher |

| 14 (CANL) - 16 (BAT) | LOW-level CAN bus line | Ignition switch off* | 6 kΩ or higher |

NOTICE:

*: Before measuring the resistance, leave the vehicle as is for at least 1 minute and do not operate the ignition switch, any other switches or the doors.

If the result is not as specified, the DLC3 may be malfunctioning. Repair or replace the harness or connector.

Electronic Circuit Inspection Procedure

Electronic Circuit Inspection Procedure

ELECTRONIC CIRCUIT INSPECTION PROCEDURE BASIC INSPECTION (a) WHEN MEASURING RESISTANCE OF ELECTRONIC PARTS (1) Unless otherwise stated, all resistance measurements are standard values measured at an ambient temperature of 20°C (68°F)...

Other information:

Toyota Yaris XP210 (2020-2026) Owner's Manual: Headlights

Without auto-light control Turn the headlight switch to turn the headlights, other exterior lights and dashboard illumination on or off. * 1: The lights are turned on while the vehicle is driven. * 2: The lights are turned on for the specified period by the auto headlight off function...

Toyota Yaris XP210 (2020-2026) Reapir and Service Manual: Customize Parameters

CUSTOMIZE PARAMETERS CUSTOMIZE AIR CONDITIONING SYSTEM (a) Customizing with the GTS. NOTICE: When the customer requests a change in a function, first make sure that the function can be customized. Be sure to make a note of the current settings before customizing...

Categories

- Manuals Home

- Toyota Yaris Owners Manual

- Toyota Yaris Service Manual

- Engine & Hybrid System

- Brake System Control Module "A" System Voltage System Voltage Low (C137BA2)

- Headlights

- New on site

- Most important about car

Fuel-Filler Lid and Cap

WARNING

When removing the fuel-filler cap, loosen the cap slightly and wait for any hissing to stop, then remove it

Fuel spray is dangerous. Fuel can burn skin and eyes and cause illness if ingested. Fuel spray is released when there is pressure in the fuel tank and the fuel-filler cap is removed too quickly.